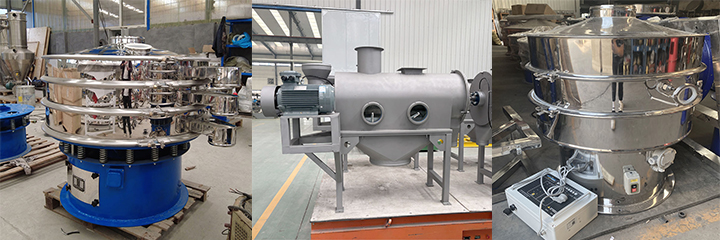

Vibrating Sieving Machine

Vibrating sieving machine play an important role in numerous industries and fields. They play an invaluable role in ensuring material purity, pre-processing for subsequent production, and improving product quality. This ensures material purity in subsequent production, improves product quality, and also increases production efficiency. Number of Screening Layers: 1-5 Screen Mesh Size: 20-600 Mesh Material: Carbon steel, stainless steel, etc. Suitable Material Forms: Powders, granules, liquids, etc.

What is a vibrating sieving machine?

A vibrating sieving machine uses vibration as its core power source, using the size of the screen mesh to classify, remove impurities, or filter material particles. By adjusting vibration parameters (amplitude and frequency) and selecting the appropriate mesh size, it can adapt to various material forms, meeting varying requirements from coarse to fine screening. It is widely used in mining, food, pharmaceutical, and chemical industries.

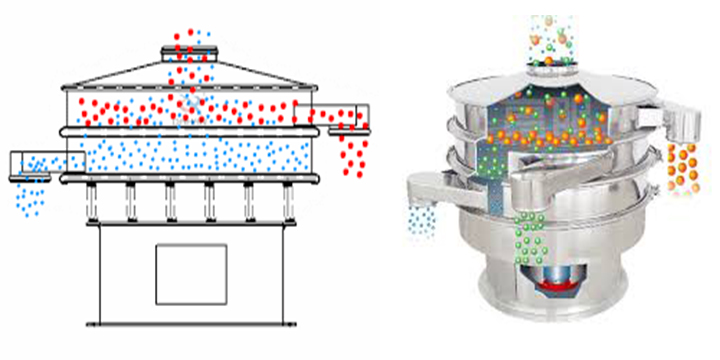

How does a vibrating sieving machine work?

A vibrating sieving machine uses a vibration motor and exciter as a vibration source to generate periodic mechanical vibrations. The vibrating screen moves along a specific trajectory (such as a straight line, circular, or elliptical path), causing the material to be tossed or slid across the surface. The varying apertures of the screen mesh allow for material separation, achieving the goals of screening, grading, and impurity removal.

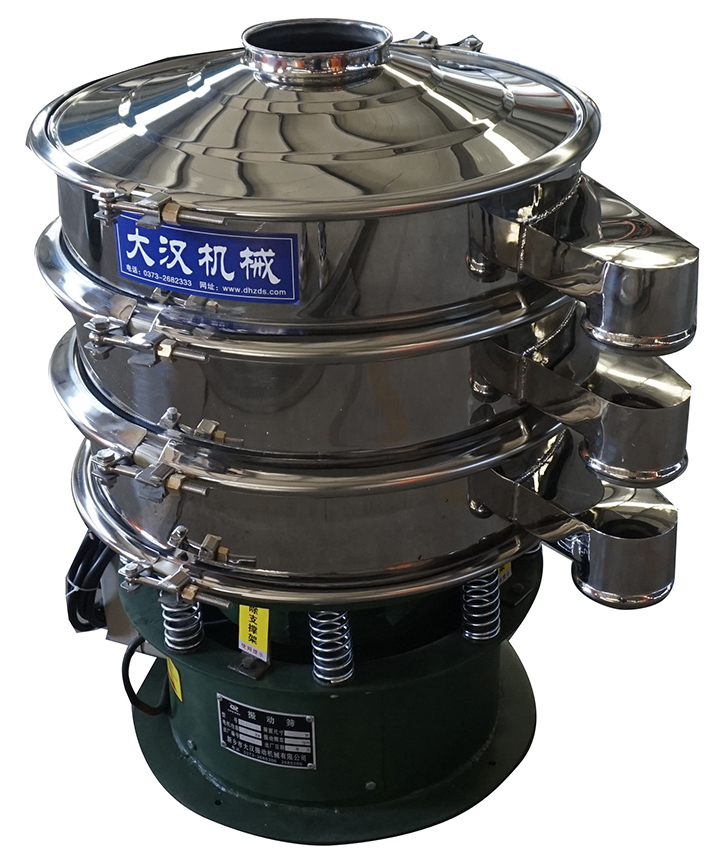

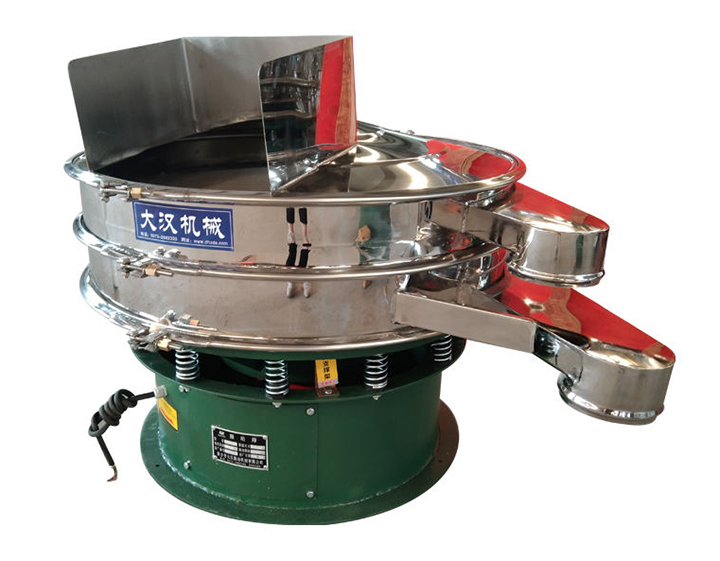

What is the structure of a vibrating sieving machine?

Screen mesh: The core component of the screening process.

Screen frame: Supports the screen mesh.

Vibrating device: A vibrating motor or exciter.

Supporting components: The frame, base, shock-absorbing springs, etc.

Inlet and outlet: The necessary components for material to enter and exit the equipment.

What are the parameters of a vibrating sieving machine?

The parameters of a vibrating sieving machine directly affect screening efficiency. For example, using a rotary vibrating screen:

| 型 号 | DH-600 | DH-800 | DH-1000 | DH-1200 | DH-1500 | DH-1800 | DH-2000 |

| 直径mm | Φ600 | Φ800 | Φ1000 | Φ1200 | Φ1500 | Φ1800 | Φ2000 |

| 筛网面积m | 0.24 | 0.45 | 0.67 | 1.0 | 1.6 | 2.43 | 3.01 |

| 筛网规格(目) | 2-500 | ||||||

| 进料粒度mm | <Φ10 | <Φ15 | <Φ20 | <Φ30 | |||

| 振次rpm | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| 有效筛面直mm | Φ560 | Φ760 | Φ930 | Φ1130 | Φ1430 | Φ1760 | Φ1960 |

| 1-5 | |||||||

| 功率Kw | 0.25 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 |

What are the advantages of a vibrating sieving machine?

Wide range of applications: A variety of vibrating screens (such as three-dimensional rotary vibrating screens, ultrasonic vibrating screens, and linear vibrating screens) can meet the screening and impurity removal needs of materials with different characteristics (such as fine powders, sticky materials, high-temperature materials, and corrosive materials), ensuring stable and accurate screening of all types of materials.

Large-Scale Screening: In large-scale production industries like mining and coal mining, vibrating screens (such as circular vibrating screens and linear screens) can rapidly grade tons of material.

High Screening Precision: In fine processing fields like pharmaceuticals and new materials, rotary vibrating screens and ultrasonic screens can achieve high-precision grading of 600 mesh and above.

High Screening Efficiency: The vibration force significantly improves material penetration, reaching over 85% screening efficiency.

Easy Operation: Adjustable vibration parameters and fast screen changing (typically 3-5 minutes).

Applications of vibrating sieving machine?

Due to their high efficiency and precision, vibrating sieving machine are widely used in material grading, impurity removal, and filtration across a variety of industries: Mining and Metallurgy (grading and screening ores, sand and gravel, etc.), Food and Pharmaceuticals (screening and removing impurities from food raw materials), Chemicals and Building Materials (screening and removing impurities from chemical raw materials and building materials), Wastewater Treatment (filtering impurities from wastewater), Agriculture and Light Industry (screening and removing impurities from grains, starch, etc.), and other sectors. with confidence.