Sand Test Sieve

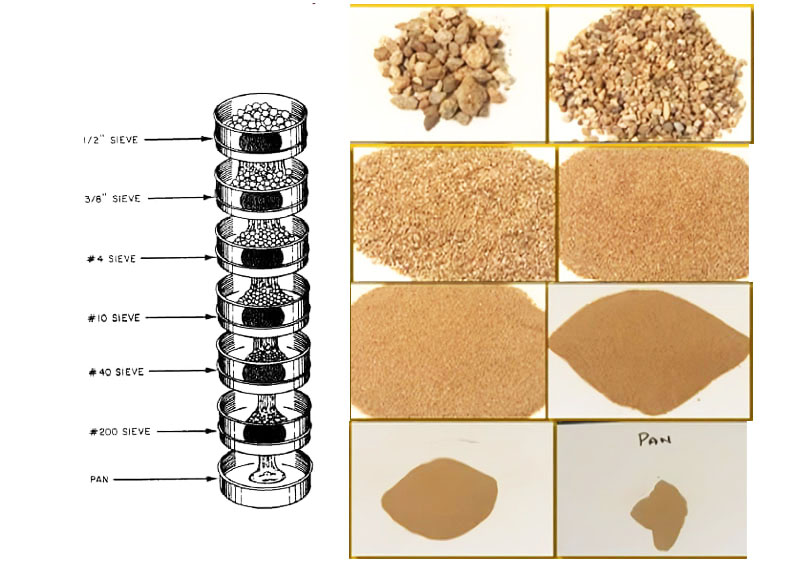

Used for particle size analysis and testing of gravel, very coarse sand, coarse sand, medium sand, fine sand, very fine sand, etc.

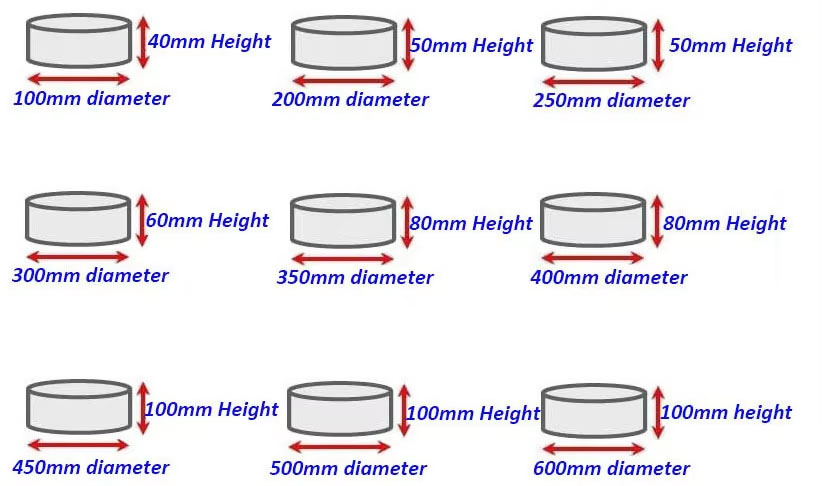

Diameter: 200mm, 300mm

Aperture: Perforated plate (>1.18mm), woven mesh (<1.18mm)

Specifications: 0.075mm, 0.15mm, 0.6mm, 1.18mm, 2.6mm, 4.75mm, 9.5mm

Material: Brass, stainless steel

What is Sand Test Sieve?

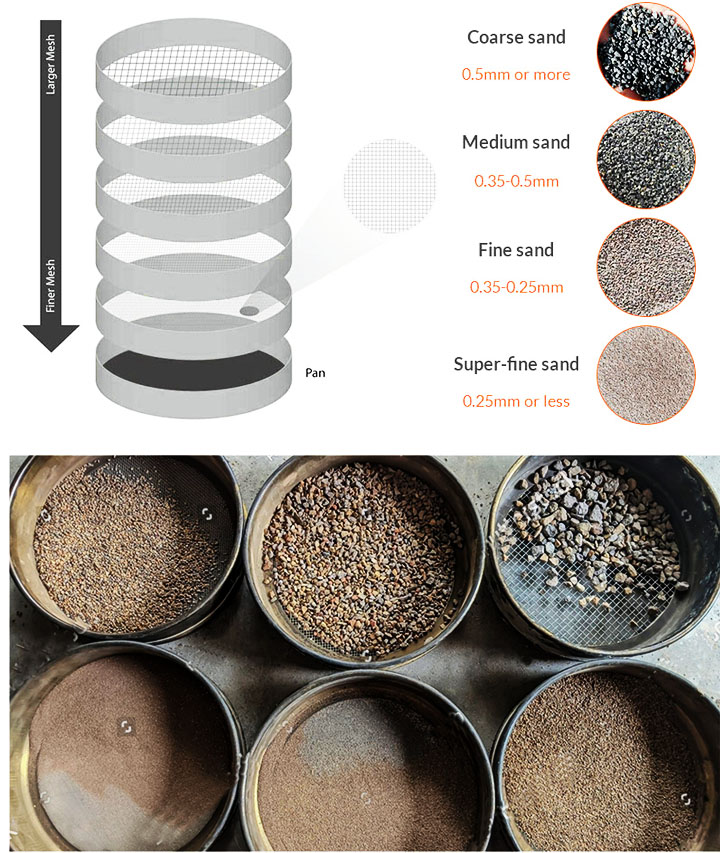

Sand Test Sieve is a standard test screening equipment used for particle size classification and analysis of sand and gravel in laboratories or production sites. It is mainly composed of a screen frame, a screen mesh and a bottom box, and adopts a wire mesh or a perforated plate structure. Its function is to accurately classify sand and gravel according to particle size through mechanical vibration or manual screening to evaluate particle distribution and determine whether the gradation meets engineering or production requirements (such as concrete aggregate, asphalt mixture, etc.). Sand Test Sieve can usually screen sand and gravel into 2~8 particle size segments, and the screening particle size range is generally 0.075mm~100mm. Common sieve hole sizes are arranged in equal proportions according to international standards (ISO/GB or ASTM), such as 0.075mm, 0.15mm, 0.3mm, 0.6mm, 1.18mm, 2.36mm, 4.75mm, 9.5mm, etc. Users can choose a specific specification of screen combination according to their needs to ensure that the screening data is accurate and reliable.

What are the applications of Sand Test Sieve?

Sand Test Sieve is mainly used for particle size analysis, quality control and grading detection of 0.075mm~100mm sand and gravel materials, and is widely used in construction, building materials, mining, geology, laboratories and other fields. Its main uses include:

Particle size classification: Screening mixed sand and gravel into different specifications according to particle size, such as gravel, coarse sand, medium sand, fine sand, etc., for optimizing the proportion of materials such as concrete, asphalt, and roadbed.

Quality control: Detect whether the sand and gravel meet industry standards (such as GB/T 14684 "Sand for Construction" and GB/T 14685 "Pebbles and Crushed Stones for Construction") to ensure that the materials meet engineering requirements.

Mud content detection: Analyze the fine powder content in sand and gravel through screening to evaluate its applicability.

| Sand and gravel category | Particle size range (mm) | Corresponding standard sieve size (example) |

| Gravel | 4.75~100 | 4.75mm、9.5mm、19mm、37.5mm |

| Extremely coarse sand | 2.36~4.75 | 2.36mm, 4.75mm |

| Coarse sand | 1.18~2.36 | 1.18mm, 2.36mm |

| China Sand | 0.6~1.18 | 0.6mm, 1.18mm |

| Fine sand | 0.3~0.6 | 0.3mm, 0.6mm |

| Extremely fine sand | 0.15~0.3 | 0.15mm, 0.3mm |

| Silty sand/mud | <0.075 | 0.075mm |

Sand Test Sieve screening method: coarse particles (>4.75mm) usually use perforated plate screens, such as Φ300mm round hole screens. Fine particles (<4.75mm) use wire woven screens, such as 0.075mm~2.36mm standard screens.

What types of Sand Test Sieve are there?

Sand Test Sieve consists of 8 sieves with different apertures and a bottom cover. The diameter of the sieve frame is usually 300mm or 200mm, which meets the requirements of GB/T14684-2011 "Sand for Construction" and GB/T14685-2011 "Pebbles and Gravel for Construction". Screen materials include:

All stainless steel 304 material: Both the screen frame and the screen are stainless steel, with strong corrosion resistance, suitable for humid environments or occasions that require frequent cleaning

Brass screen frame + phosphor bronze mesh: traditional configuration, relatively economical price

Chrome-plated iron screen frame: the lowest cost, attention should be paid to rust prevention

Why choose Sand Test Sieve?

Sand Test Sieve is an important tool for detecting the particle size distribution of sand and gravel. The traditional manual screening method is inefficient and has large errors. The mesh of our equipment is strictly produced in accordance with ISO3310-1/GB6003.1 standards, with extremely small tolerances, ensuring the comparability of test results of different batches. For example, the aperture of our 140-mesh screen is 106μm, which is highly consistent with the American Taylor sieve 150# (105μm). From coarse screen (4 mesh/4.75mm) to ultra-fine screen (500 mesh/0.025mm), a full range of options are available. A set of equipment meets the full range of screening needs from gravel to stone powder, and can simultaneously separate 2-8 sand and gravel segments of different particle sizes with an accuracy of up to ±0.001mm. In addition, the screen and the screen frame are fixed by soldering, with a wall thickness of 0.6-6mm. After stretching and polishing, it is non-deformed and non-magnetic, resistant to high temperatures of 300℃, and will not loosen after long-term use.

How does Sand Test Sieve work?

When the Sand Test Sieve is working, the sand and gravel samples are shaken manually or mechanically to make relative movement on the sieve surface. Particles smaller than the sieve holes pass through the sieve and become undersize, while particles larger than the sieve holes remain on the sieve. Through step-by-step screening from coarse to fine, the mass percentage of each particle size range is finally obtained.

Sand Test Sieve Specifications

| Parameters | Specifications | Remarks |

| Screen frame diameter | 200mm/300mm | 300mm is the standard size of sand for construction |

| Screen frame height | 50mm/75mm | Height affects sample loading |

| Number of components | 8 sieves + bottom cover | Regular configuration |

| Screen material | Stainless steel/brass/phosphor bronze | Stainless steel has the best corrosion resistance |

| Screen frame material | Stainless steel 304/chrome-plated iron/plastic | All stainless steel has the longest service life |

| Typical aperture | 10.0,5.0,2.5,1.25,0.63,0.315,0.16,0.08mm | Common series of sand for construction |

Sand Test Sieve mesh size correspondence table

The mesh size of Sand Test Sieve complies with national standards (GB/T 6003.1-1997) and international standards (ISO 3310-1). Common specifications are as follows

| Basic mesh size (mm) | Wire diameter (mm) | Screening area percentage (%) | Corresponding mesh size (approximate) |

| 4.75 | 1.4 | 49 | 4 mesh |

| 2.36 | 1.0 | 49 | 8 mesh |

| 1.18 | 0.63 | 43 | 16 mesh |

| 0.6 | 0.3 | 41 | 30 mesh |

| 0.3 | 0.15 | 38 | 50 mesh |

| 0.15 | 0.08 | 36 | 100 mesh |

| 0.075 | 0.045 | 34 | 200 mesh |

Mesh number refers to the number of sieve holes per inch (25.4mm) in length. The larger the mesh number, the finer the particles.

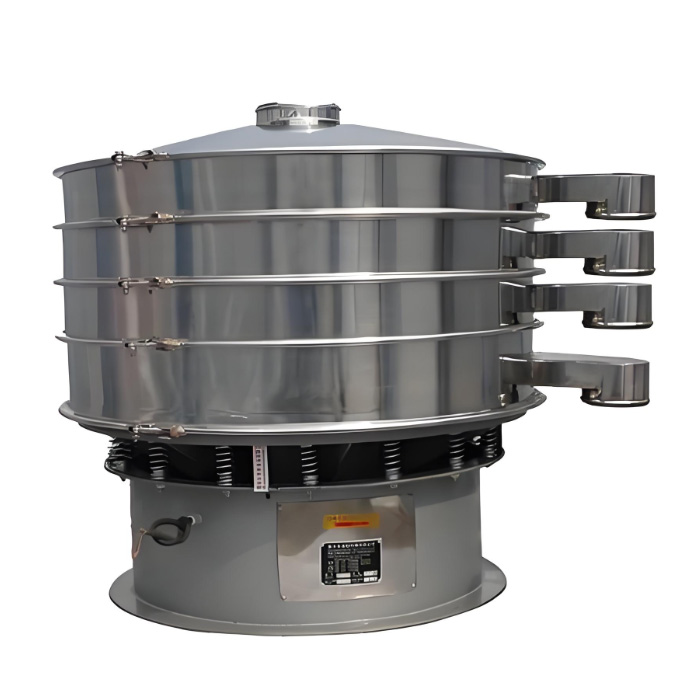

During actual screening, a vibrating screen machine (such as a slapping type) is required to improve accuracy

How to choose a suitable Sand Test Sieve?

When choosing a sand test sieve, the following factors need to be considered comprehensively:

Choose according to the type of sand and gravel

| Sand and gravel type | Recommended test sieve type | Key sieve mesh number |

| Coarse gravel (>5mm) | Square punching sieve | 5,10,20mm |

| Medium coarse sand (0.6-5mm) | Standard set sieve/vibrating sieve | 2.36,4.75mm |

| Fine sand (0.15-0.6mm) | Vibrating test sieve | 0.3,0.6mm |

| Stone powder (<0.15mm) | Slap test sieve | 100,200 mesh |

Select according to sample quantity: for small samples (<500g), choose a standard sieve with a diameter of 200mm; for medium samples (0.5-5kg), choose a standard sieve with a diameter of 300mm

Select according to accuracy requirements: for routine testing, use a standard sieve with a relative error of ±3%; for high-precision testing, choose a vibrating test sieve with an error of ±1%; for scientific research-level testing, an automated screening system equipped with an electronic balance is required.

Select according to frequency of use: for occasional use, choose an economical chrome-plated sieve frame; for daily testing, choose stainless steel 304 material.

Special needs consideration: use a full stainless steel structure for corrosive environments; add an ultrasonic screen cleaning system for ultra-fine screening

Gravel Sifting Machine

Gravel Sifting Machine Sieve For Polystyrene Pellets

Sieve For Polystyrene Pellets Gravel Separator Machine

Gravel Separator Machine Gravel Separator Machine

Gravel Separator Machine