square cone mixer

The square cone mixer is an efficient and reliable mixing equipment, especially suitable for mixing powdered and granular materials with high requirements for mixing uniformity and discharge, such as mixing of solid preparations such as drugs, foods, dairy products, chemical reagents, etc., and is particularly suitable for mass production.

Speed: 18rpm Motor power: 0.75kw Mixing time: 1-99 minutes One-time mixing: 100-6000 (kg) (if more than 6000kg can be customized as needed) Application: liquids, powders, viscous fluids, liquids, particles, powders containing suspended solids

What is a square cone mixer?

The square cone mixer is a material mixing equipment commonly used in the pharmaceutical, food, chemical and other industries, suitable for uniform mixing of powders and granular materials. The equipment consists of a square cone container, which repeatedly rolls, diffuses and convects the material in the container through rotation, thereby achieving efficient mixing.

The typical volume is between 100L and 2000L, which is suitable for different batch production needs. The material usually needs to be sieved before mixing, and the sieve mesh is generally 60 to 120 mesh to ensure the uniformity of the mixing effect. The square cone mixer has a simple structure, complete material discharge, and a mixing uniformity of more than 95%. It is suitable for process occasions with high requirements for material mixing accuracy.

What are the classifications of square cone mixers?

| Item/model | square cone mixer | high-speed mixer | horizontal plowshare mixer | horizontal ribbon mixer |

| Image |

|

|

|

|

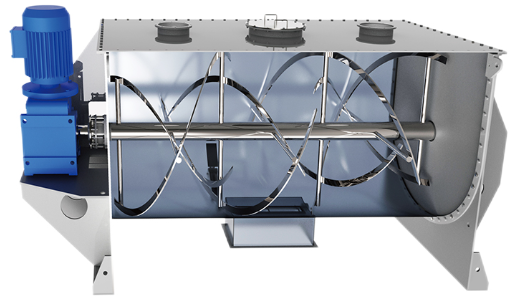

| Structural form | square cone barrel, rotating mixing | vertical with high-speed mixing blades | horizontal U-shaped barrel with plowshare + flying knife structure | horizontal U-shaped barrel with double spiral ribbon structure |

| Mixing method | overall rotation | blade high-speed shearing + bottom mixing | plowshare throwing + flying knife shearing | spiral ribbon propulsion and reverse mixing |

| Capacity range | 5L–3000L | 5L–1000L | 50L–5000L | 100L–10000L |

| Mixing time | 10–20 minutes (conventional materials) | 3–8 minutes (fast mixing) | 5–10 minutes (moderate) | 10–20 minutes (slightly longer time) |

| Mixing uniformity | High (Cv≤3%) | High (Cv≤2%) | High (Cv≤5%) | Medium (Cv≤5–10%) |

| Applicable materials | Pharmaceutical powder, food, fine chemicals | Viscous powder, granules, auxiliary material mixing | Viscous materials, additives, pastes | General powder, granules, feed, etc. |

| Applicable industries | Pharmaceuticals, food, fine chemicals, health products | Food, cosmetics, additives, medicines, etc. | Pesticides, building materials, chemicals, compound fertilizers, etc. | Feed, fertilizers, putty powder, quartz sand, etc. |

| Features | Simple structure, no dead angle, easy to disassemble and clean | Fast mixing speed, suitable for fast batch mixing | Good effect on viscous and agglomerated materials, strong dispersion | Simple structure, suitable for large-scale continuous mixing |

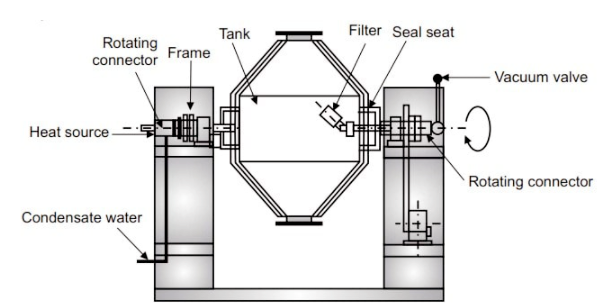

Working principle of square cone mixer

Square cone mixer usually achieves material mixing in the following ways:

①Container rotation: The square cone container rotates around an axis, so that the material in the container is constantly flipped and mixed under the action of gravity.

②Baffle function: Some square cone mixers are equipped with fixed baffles inside the container. When the container rotates, the material will be blocked and impacted by the baffle, thereby enhancing the mixing effect.

③Spiral stirring: Some designs use cantilevered spiral stirrers to rotate in the conical container, lifting the material from the bottom to the top, and then falling by gravity to form a circular flow to achieve mixing.

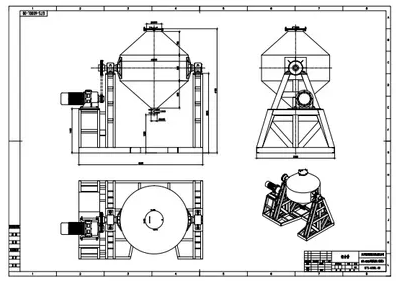

Structural composition of square cone mixer

The basic structure of the square cone mixer mainly includes:

Square cone mixing cylinder: It is the main container for mixing. It is generally made of stainless steel and the inner wall is polished to prevent material adhesion.

Transmission system: It is usually composed of a motor, a reducer and a sprocket/belt, which is used to drive the mixing cylinder to rotate.

Bracket and rotating mechanism: Support the entire mixing cylinder and provide rotational power.

Discharging device: After mixing is completed, the cylinder rotates to the bottom of the discharge port at a certain angle and discharges the material through the valve.

Control system: It is used to set functions such as mixing time, speed, automatic shutdown, etc. Some models can realize PLC control.

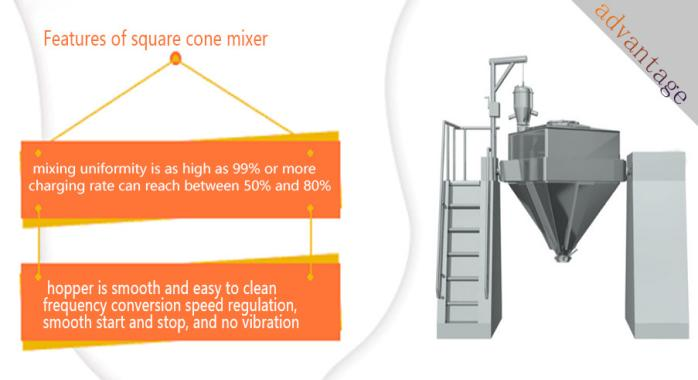

Features of square cone mixer

When the charging ratio is 0.8, the mixing uniformity is as high as 99% or more, and the charging rate can reach between 50% and 80%.

The inner wall of the hopper is smooth and easy to clean, without dead corners. The mixer mixes in a fully enclosed state, forming a dust-free production environment without cross contamination.

The square cone structure and rotational motion of the square cone mixer can effectively make the materials of different components fully contact and mix.

The bottom of the cone is conducive to the smooth discharge of the material after mixing, with less residue. The feed valve is equipped with an anti-misoperation device for easy disassembly and cleaning.

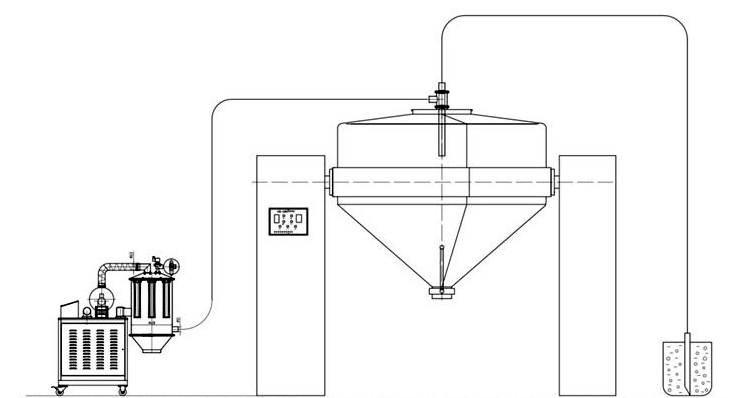

The working parameters such as mixing time and speed can be set, frequency conversion speed regulation, smooth start and stop, and no vibration. It can be customized according to different production needs, such as adding vacuum feeding, liquid spraying and other functions.

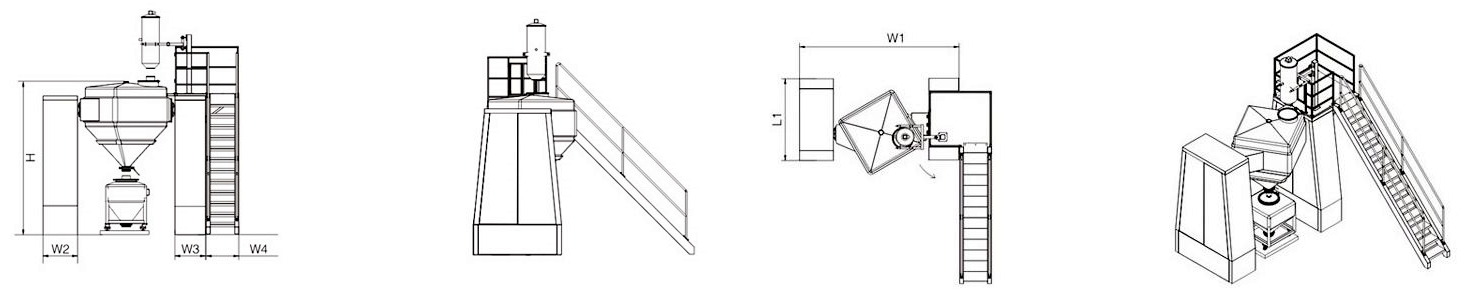

Square cone mixer product parameters

| Model | Dimension (MM) | Total | Volume | Max.loading capacity | Rotation Speed | Weight | Power | |

| L | W | H | L | KG | Rpm/min | KG | KW | |

| DH-300 | 1850 | 1280 | 1980 | 300 | 150 | 3-12 | 600 | 2.2 |

| DH-500 | 2100 | 1620 | 2420 | 500 | 250 | 3-12 | 800 | 3 |

| DH-1000 | 2750 | 2100 | 2900 | 1000 | 500 | 3-12 | 1200 | 4 |

| DH 1500 | 3000 | 2200 | 3000 | 1500 | 750 | 3-12 | 1500 | 4 |

| DH-2000 | 3200 | 2350 | 3150 | 2000 | 1000 | 3-12 | 1900 | 5.5 |

| DH-2500 | 3400 | 2500 | 3300 | 2500 | 1250 | 3-12 | 2400 | 0.5 |

| DH-3000 | 3750 | 3050 | 3850 | 3000 | 1500 | 3-12 | 2900 | L1 |

| DH-4000 | 3850 | 3075 | 3875 | 4000 | 2000 | 2-8 | 3500 | 5 |

| DH-5000 | 4200 | 3200 | 4000 | 5000 | 2500 | 2-8 | 4200 | 18.5 |

| DH-6000 | 4500 | 3300 | 4300 | 6000 | 3000 | 2-8 | 5200 | 22 |

| DH-8000 | 4900 | 3380 | 4380 | 8000 | 4000 | 2-8 | 6500 | 30 |

| DH-10000 | 5300 | 4300 | 5100 | 10000 | 5000 | 2-8 | 8000 | 31 |

Application of square cone mixer

Square cone mixer is mainly used for uniform mixing of solid particles and dusty materials in the pharmaceutical industry. It is widely used in pharmaceutical, chemical, food, metallurgy, feed and other industries. It is especially suitable for mixing materials with similar physical properties and uniform particle size requirements. In the pharmaceutical industry, it is often used for premixing of APIs and excipients; in the chemical industry, it can be used for mixing a variety of additives and adjuvants; in the food field, it is suitable for batch mixing of products such as seasoning powder and nutritional powder. Due to its good airtightness and high mixing uniformity, the square cone mixer has obvious advantages in preventing cross contamination and improving mixing efficiency.

① Pharmaceutical industry: used for mixing powders, granules, materials before tablet coating, etc., to ensure high mixing uniformity, no cross contamination and dust, and to ensure the stability and consistency of drug quality.

② Food industry: can be used for mixing powdered or granular materials such as seasonings, additives, milk powder, flour, etc., so that food ingredients are evenly distributed and the taste and quality of food are stable.

③ Chemical field: suitable for mixing pigments, dyes, powder coatings, chemical raw materials, etc., and can evenly mix chemical materials of different components to provide stable raw materials for subsequent production processes.

④ Feed industry: used to mix various feed raw materials, such as corn flour, soybean meal, fish meal, vitamins, minerals, etc., so that the nutrients in the feed are evenly distributed to meet the nutritional needs of animals at different growth stages.

Supplier of square cone mixer

Xinxiang Dahan Machinery is a manufacturer that provides powder equipment. The volume range of its square cone mixers is generally 100L to 2000L. The equipment is mostly made of 304 or 316L stainless steel, which is suitable for industries with high requirements for hygiene and corrosion. Dahan Machinery's square cone mixer has functions such as automatic positioning, automatic clamping, automatic lifting and automatic discharging. It can be used with screening equipment to achieve material particle size control, such as using different screens such as 60 mesh, 80 mesh, and 100 mesh for pretreatment to meet the process requirements of mixing uniformity and product particle size.