Ultrasonic Sieving Machine

By combining ultrasonic technology with traditional screening, ultrasonic sieving machine overcome the bottlenecks of traditional screening in processing fine particles, high viscosity, and easily agglomerated materials. They are essential equipment for fine powder screening. Number of screening layers: 1-5 Screening mesh size: 20-3000 mesh Ultrasonic frequency: 20-40kHz Ultrasonic amplitude: 5-50μm

What is an ultrasonic sieving machine?

An ultrasonic sieving machine is a high-efficiency screening device that integrates an ultrasonic vibration system with traditional screening equipment. It converts the high-frequency electrical signal generated by an ultrasonic generator into high-frequency mechanical vibrations, which are then transmitted to the screen surface, causing the screen to vibrate minutely and rapidly. This effectively solves common problems with traditional screening, such as screen clogging, low screening efficiency, and insufficient precision. It is widely used in high-precision and high-efficiency screening applications.

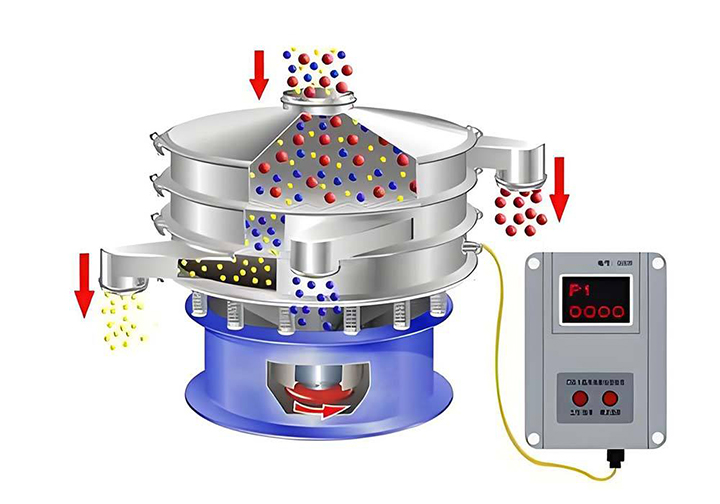

How does an ultrasonic sieving machine work?

An ultrasonic sieving machine uses a power unit and ultrasonic wave generator to work together to affect material after it enters the screen through the feed inlet. The vibration motor generates vibrations, driving the screen body to force the material to move in a specific trajectory. Simultaneously, the ultrasonic transducer transmits the high-frequency vibrations generated by the ultrasound directly to the screen mesh, causing it to generate high-frequency, low-amplitude vibration energy perpendicular to the traditional vibration direction. This high-frequency, low-amplitude vibration energy effectively breaks down the adsorption and agglomeration between material particles, preventing particle blockage. It also accelerates the flow of material through the screen mesh, improving screening efficiency and accuracy.

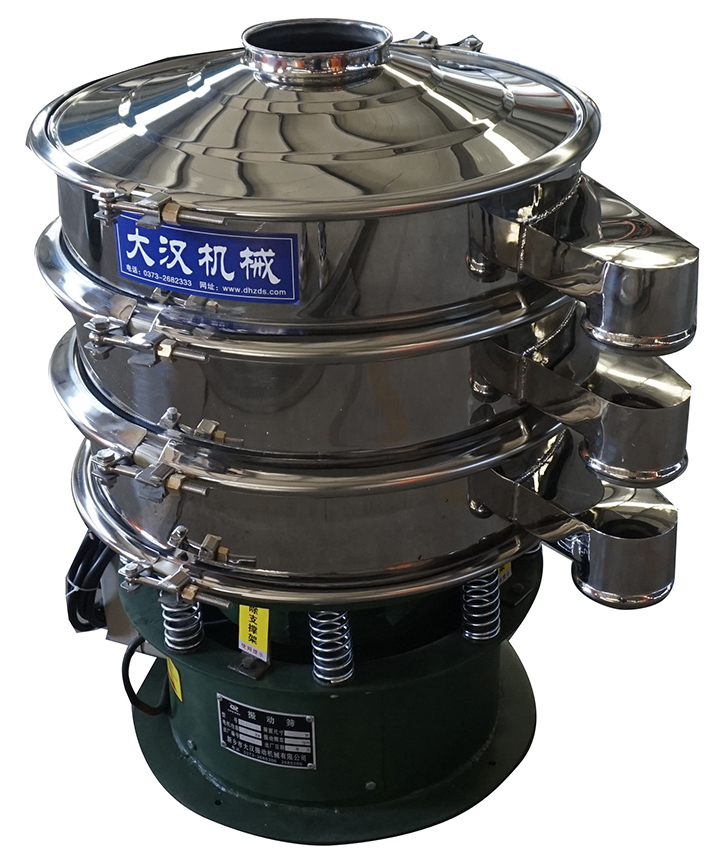

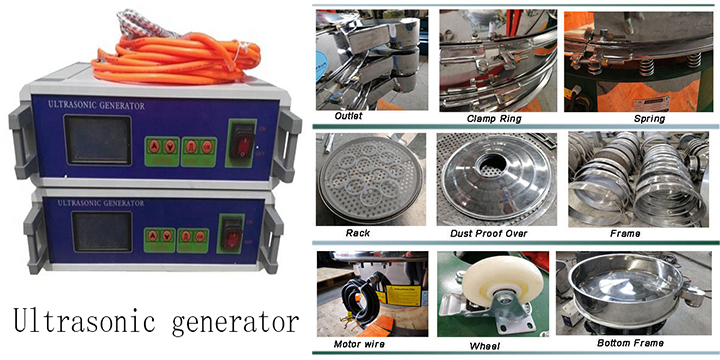

What is the structure of an ultrasonic sieving machine?

Screen mesh: The core component of the screening process.

Screen frame: Carries the screen mesh.

Inlet and outlet: Required components for material to enter and exit the equipment.

Frame: Supports the entire screening machine, ensuring its stability.

Shock absorber: Absorbs some of the vibration force, reducing any negative impacts on the equipment and the surrounding environment.

Vibration device: A vibration motor generates traditional vibrations.

Ultrasonic system: An ultrasonic generator (provides ultrasonic energy), an ultrasonic transducer (converts high-frequency electrical signals into high-frequency mechanical vibrations), and an ultrasonic connecting cable (connects the ultrasonic generator and transducer).

What are the parameters of an ultrasonic sieving machine?

|

试 机 型 号 |

测 试 物 料 |

网 目 | 普通振动筛 | 超声波振动筛 |

| 1000 | 碳化硅 | 500目 | 无法筛分 | 1500kg/h |

| 1000 | 硬质合金钨粉 | 600目 | 15分钟没筛出细粉 | 30kg/h |

| 1000 | 维生素C粉 | 100目 | 1kg/h | 120-150kg/h |

| 600 | 花粉 | 400目 | 15分钟没筛出细粉 | 15分钟筛出 |

| 1000 | 镍、锌、钴粉 | 400目 | 10kg/h | 300kg/h |

| 1000 | 钕铁硼粉 | 300目 | 30分钟有32.2%筛余物 | 30分钟有6.9%筛余物 |

| 1000 | 金钢砂微粉 | 300目 | 无法筛分 | 1300kg/h |

| 1200 | 三氧化二锑 | 80目 | 700kg/h | 2000kg/h |

| 型 号 | 有效直径 | 筛分面积 | 筛网规格 | 层 数 | 输入电源 |

超声波 型 号 |

换能器 位 置 |

频 率 |

超声波 档 位 |

功 率 |

| mm | m2 | 目 | 层 | V/HZ | KHz | Kw | ||||

| DHC-200 | 200 | 0.03 | 10-1200 | 1-7 | 220/50 | ZTC-7 | 外置 | 38KHz |

连续1-9档 脉冲2档 |

0.18 |

| DHC-400 | 340 | 0.09 | 60-635 | 1-3 |

振动筛 380/50 超声波220/50 |

内置/外置 | 0.25 | |||

| DHC-600 | 540 | 0.23 | 0.55 | |||||||

| DHC-800 | 730 | 0.42 | 0.75 | |||||||

| DHC-1000 | DHC-1000 | 900 | 0.64 | 1.1 | ||||||

| DHC-1200 | 1100 | 0.95 | 1.5 | |||||||

| DHC-1500 | 1400 | 1.54 | 2.2 | |||||||

| DHC-1800 | 1700 | 2.27 | 3.0 |

What are the advantages of an ultrasonic sieving machine?

Strong Screening Capacity: This eliminates the clogging problem that traditional screens often encounter when processing fine particles, high-humidity, or sticky materials. High-frequency, low-amplitude vibrations quickly break up adsorption between particles and screen meshes, as well as particle agglomeration. This improves screening efficiency and accuracy.

High Screening Efficiency: Compared to traditional screens, this system can improve efficiency by 30%-100%, especially for fine powders.

High Screening Precision: Suitable for screening mesh sizes of 600 mesh and higher.

Wide Screening Range: By adjusting the amplitude and frequency generated by the ultrasonic system, it can effectively adapt to various screening challenges.

What are the applications of an ultrasonic sieving machine?

Ultrasonic screening machines, with their anti-clogging properties, high screening accuracy, high screening efficiency, and adaptability to screening conditions difficult for conventional screens, are widely used in various industries. They play a key role in applications requiring fine screening, driving improvements in product quality and optimizing production efficiency in related fields. Pharmaceutical and health care products industry (grading, screening and impurity removal of pharmaceutical excipient powders and health care product raw materials), chemical and new materials (screening, grading or impurity removal of dyes, chemical additives, nano-ceramic powders, etc.), food industry (screening flour, cocoa powder, seasoning powder, etc.), electrical industry (screening and impurity removal of electronic slurry, battery materials) and other industries that require fine screening.