Recovery of wet electrolytic gold extraction equipment 99.999% high-purity gold

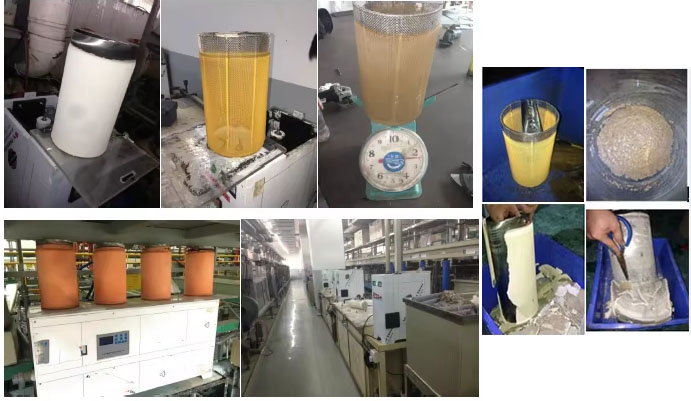

Combining wet chemical dissolution and electrolytic refining technology can purify crude gold or gold-containing waste to a high purity of 99.999%

Price: $300-$30,000

Gold Purity: 99.999%

Recovery Rate: 98–99.5%

Processing Speed: 4–12 hours/batch

Energy Use: 0.8–1.2 kWh/g Au

What is Recovery of wet electrolytic gold extraction equipment 99.999% high-purity gold?

In today's fast-growing electronics industry, gold recovery from e-waste and industrial waste has become a key part of sustainable resource management. Traditional methods such as cyanide leaching or smelting are dangerous, inefficient and environmentally damaging. Our Recovery of wet electrolytic gold extraction equipment 99.999% high-purity gold has revolutionized the gold recovery process by extracting 99.999% high-purity gold with minimal environmental impact.

Designed for high efficiency, low energy consumption and zero emissions, this advanced system is an ideal solution for refineries, e-waste recyclers and mining companies.

Recovery of wet electrolytic gold extraction equipment 99.999% high-purity gold What types are there?

We offer three main configurations: laboratory, industrial batch and fully automated continuous systems to meet different processing needs.

| Type | Capacity | Purity | Applications |

| Laboratory-Scale System (LE-100) | 1–5 kg/day | 99.999% | Research, small-scale refining, quality control |

| Industrial Batch System (IE-500) | 50–500 kg/day | 99.999% | Mid-sized refineries, e-waste processors |

| Fully Automated Continuous System (CE-3000) | 1–5 tons/day | 99.999% | Large-scale mining, commercial gold recovery plants |

Recovery of wet electrolytic gold extraction equipment 99.999% high-purity gold What are the advantages?

Ultra-High Purity (99.999%): Ideal for electronics & jewelry industries

Eco-Friendly Process: No cyanide, mercury, or toxic byproducts

High Recovery Rate (98–99.5%): Maximizes gold yield from low-grade sources

Low Energy Consumption: 50% less power than traditional smelting

Modular & Scalable: Expandable for growing business needs

Automated Operation: Minimal manual intervention required

Recovery of wet electrolytic gold extraction equipment 99.999% high-purity gold What are the applications?

Our system is widely used in:

E-Waste Recycling: Extract gold from PCBs, CPUs, and connectors

Mining & Refining: Process gold ores and tailings efficiently

Jewelry & Dental Scrap: Recover high-purity gold from manufacturing waste

Industrial Catalysts: Extract gold from spent chemical catalysts

Recovery of wet electrolytic gold extraction equipment 99.999% high-purity gold customer case

UK Royal Mint’s Gold Recovery Plant: Needed a sustainable way to recover gold from circuit boards.

Solution: Implemented our electrolytic extraction system, achieving 99.9% purity at 4400 tons/year capacity710.

Chinese E-Waste Refinery: High pollution from traditional cyanide leaching.

Solution: Switched to our wet electrolytic system, reducing waste by 95% while increasing gold yield