Precious metal refining equipment for extracting gold and silver from electronic waste

It can quickly extract gold and silver from electronic waste, and its purification rate can reach 99.99%

Price: $56,000-$114,300

Processing Capacity: 1 kg/day – 1,000 kg/day

Recovery Rate: Gold: 90-98% · Silver: 85-95%

Power Consumption: 5 kW – 200 kW (scalable)

Refining Method: Hydrometallurgical / Electrochemical

Purity Level: Up to 99.99% (4N)

What is Precious metal refining equipment for extracting gold and silver from electronic waste?

Our Precious metal refining equipment for extracting gold and silver from electronic waste is engineered to process various types of electronic waste, including circuit boards, mobile phones, computer components, and more. We understand the complexities of e-waste recycling and have developed robust and reliable systems to effectively separate and extract gold and silver. Our commitment to innovation has led to the development of our signature bagged refining equipment, offering a streamlined and convenient approach to precious metal recovery.

What types of Precious metal refining equipment for extracting gold and silver from electronic waste are there?

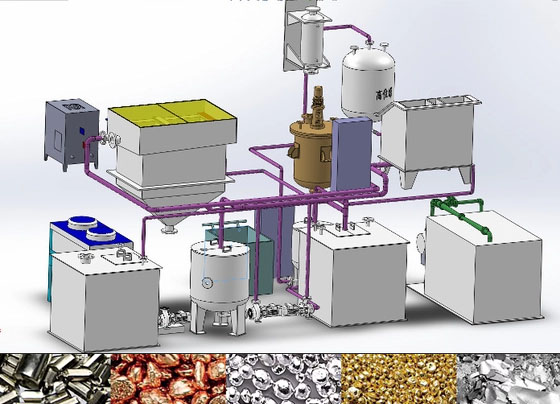

Our precious metal refining equipment is categorized based on processing capacity and technology:

Small-Scale Refining Systems: Ideal for startups & labs (1-10 kg/day)

Medium-Scale Refining Plants: Suitable for mid-sized recyclers (10-100 kg/day)

Industrial-Scale Refining Solutions: For large e-waste processors (100+ kg/day)

What are the advantages of Precious metal refining equipment for extracting gold and silver from electronic waste?

High Recovery Rates (90%+ Gold & Silver Extraction): Optimized for maximum yield.

Eco-Friendly & Low-Chemical Processes: Reduces hazardous waste compared to traditional methods.

Automated & User-Friendly: Minimizes manual labor and operational risks.

Customizable Solutions: Tailored for different e-waste types (PCBs, connectors, chips).

Fast Processing Time: Efficient refining cycles for quicker ROI.

How does Precious metal refining equipment for extracting gold and silver from electronic waste work?

Our refining systems utilize advanced hydrometallurgical and electrochemical processes to extract gold and silver from e-waste:

Crushing & Sorting: E-waste is shredded and separated to isolate metal-rich components.

Leaching & Dissolution: Precious metals are dissolved using non-toxic or low-toxicity solvents (alternative to cyanide-based methods).

Electrowinning & Precipitation: Gold and silver are recovered via electrolysis or chemical reduction.

Purification & Smelting: Final refining ensures 99.9% pure gold and silver.

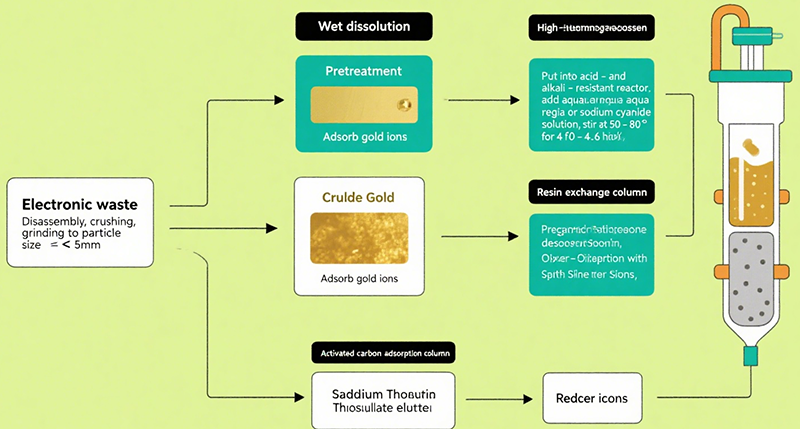

What is the process flow of Precious metal refining equipment for extracting gold and silver from electronic waste?

The process flow of Precious metal refining equipment for extracting gold and silver from electronic waste includes the steps of "pretreatment-fire smelting-electrolytic refining-wet leaching-reduction precipitation-refining and purification", as follows:

Pretreatment: Electronic waste is disassembled, crushed, and sorted to remove non-metallic impurities such as plastics and ceramics to obtain raw materials containing precious metals.

Fire smelting: The raw materials are mixed and smelted with flux (such as borax and sodium carbonate) in a high-temperature furnace, and the precious metals are enriched in copper or lead alloys to form "precious lead".

Electrolytic refining: Precious lead is used as an anode for electrolysis, copper and other base metals are dissolved, and gold and silver are deposited in the anode mud.

Wet leaching: The anode mud is dissolved by aqua regia or cyanide, and a solution containing gold and silver is obtained after filtration.

Reduction precipitation: Add a reducing agent (such as sodium sulfite, oxalic acid) to precipitate crude gold and silver.

Refining and purification: Crude gold is purified to 99.99% by electrolysis or chlorination; crude silver is electrolyzed or chemically reduced to obtain high-purity silver.

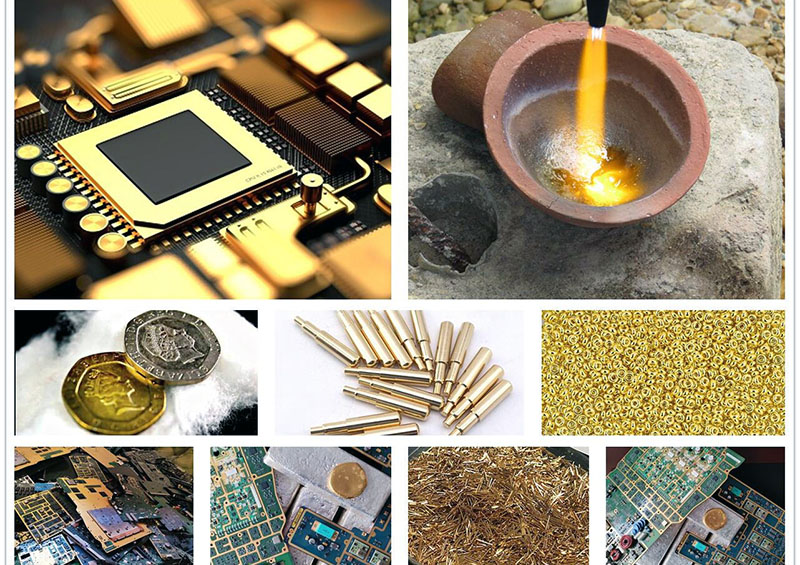

What are the applications of Precious metal refining equipment for extracting gold and silver from electronic waste?

Our systems are widely used in:

E-Waste Recycling Plants: Recovering gold from PCBs, RAM, CPUs.

Jewelry & Bullion Refineries: Purifying scrap gold and silver.

Mining & Metallurgical Industries: Extracting precious metals from ores and tailings.

Government & Environmental Agencies: Sustainable e-waste management.

Precious metal refining equipment for extracting gold and silver from electronic waste customer case

A European e-waste recycler increased gold recovery by 35% using our refining system.

A U.S.-based refinery reduced chemical waste by 50% with our eco-friendly process.

An African gold processor scaled operations 10x with our industrial refining unit.