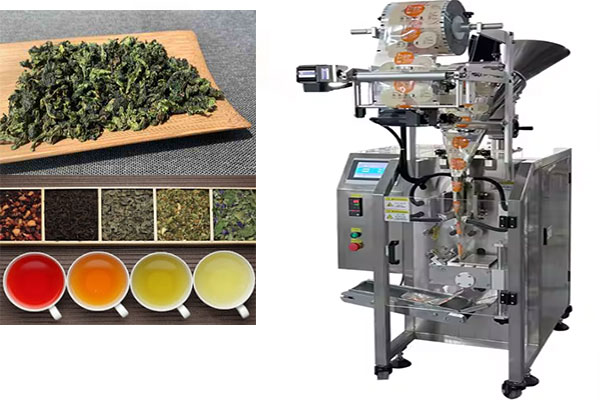

Tablet and powder packaging machine

Wednesday January-21 2026 17:50:20

Tablet and powder packaging machine can package solid or powdered tablets and powders. The packaging speed is 80-120 bags per minute, with sealing types including three-side seal, four-side seal, or vertical seal, and sealing methods primarily using heat sealing or ultrasonic sealing. The equipment occupies approximately 2-3 square meters. The equipment is highly automated, integrating automatic metering, filling, and sealing functions, and can be integrated into a production line to achieve fully automated operation from material feeding to finished product output.

Tablet and Powder Packaging Machine Functions

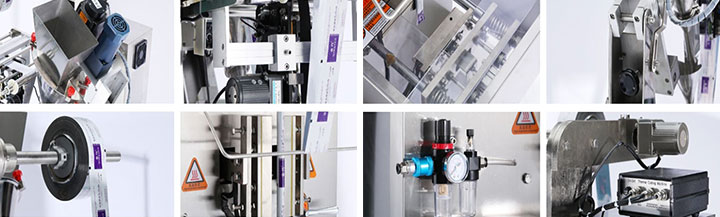

Whether it's tablets or powder, the packaging process of a tablet and powder packaging machine is similar, involving feeding and counting, unloading, sealing, inspection, and printing. Feeding commonly uses vibratory feeders or conveyor belts to guide tablets into the counting system. The machine automatically counts the tablets or weighs the powder according to a set quantity. After counting, the tablets are fed into packaging containers, and the tablets and powder are placed into packaging bags, which are then sealed using heat sealing. After sealing, the production date and barcode are printed. Some machines have a missing product detection function, which can inspect packaged tablets and powders. After the inspection is completed, a finished packaging bag can be output.

Tablet and powder packaging machine parameters

| Description | Example |

| Machine Name | Tablet and powder packaging machine |

| Packaging Type | Tablet / Powder |

| Package Form | Aluminum-plastic Blister / Vertical Bag / Can |

| Speed | 20-120 bags/min |

| Metering Method | Tablet Counting / Auger Feeding / Weighing |

| Tablet Size | 5-25 mm |

| Powder Particle Size | ≤ 60 mesh |

| Packaging Material | PVC / PE / PET / Aluminum Foil Composite Film |

| Sealing Temp. | 0-300 ℃ |

| Power Supply | 220 V / 380 V, 50/60 Hz |

| Total Power | 3-6 kW |

| Weight | 800-2,000 kg |

| Dimensions | 1800×1200×1600 mm |

| Control System | PLC + Touch Screen |

Advantages of a Tablet and powder packaging machine

Because tablets and powders are sensitive to humidity, air, and microorganisms, a tablet and powder packaging machine can seal them in aluminum foil bags, plastic bottles, or cardboard boxes to prevent moisture or spoilage. Manual packaging of tablets or powders is slow and prone to errors, while packaging machines can quickly complete the processes of metering, bagging, and sealing. Batch numbers, production dates, and instructions for use can be printed on the packaging, increasing the safety and traceability of tablets and powders.

Tablet and powder packaging machine price

The price of a tablet and powder packaging machine depends on factors such as the number of bags packaged per minute and the machine model. For a fully automatic vertical packaging machine with a packaging capacity of 10-20 bags/minute and a power of 350 watts, the price is around $650. An industrial-grade packaging machine capable of packaging 60 bags per minute costs around $2800. This price can be used as a reference to select a suitable machine.

Tablet and Powder Packaging Machine Case Study

A medium-sized pharmaceutical company's original packaging equipment was inefficient and lacked precision, leading to production bottlenecks and material waste. They later introduced a high-speed automated tablet and powder packaging machine. This machine integrates vision inspection and gravity feedback systems, achieving automatic counting, filling, and sealing. After implementation, the packaging speed increased from 30 bags per minute to 120 bags per minute, reducing powder raw material waste by approximately 15 tons annually. By changing the molds and setting parameters, the machine met the company's needs for multi-variety, small-batch orders, improving packaging quality.

Tablet and powder packaging machines are available in various types, such as small powder filling machines and fully automatic packaging machines. These types can package dry powders, tablets, and other materials. When selecting a machine, you can provide the supplier with your packaging output requirements, and the manufacturer will recommend a suitable model or provide customized manufacturing.