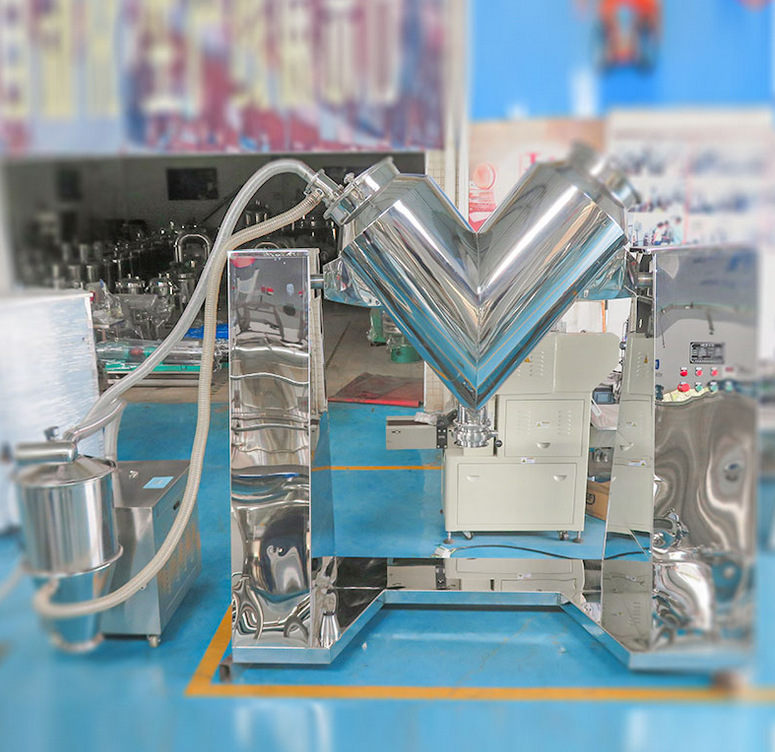

Vacuum feeder for mixer

Vacuum feeder for mixer perfect combination of provides efficient, clean and safe material handling systems for food, pharmaceutical, chemical, new energy and other industries.

Spindle speed range (rpm): 1 - 12 rpm

Voltage: 380-440 volts or customized voltage.

Material: SUS304, SUS316, SUS316L, stainless steel

Size (length * width * height):750*780*1600 mm (customizable)

Capacity: 40 liters, 50 liters, 100 liters, 1000 liters, 500 liters, 200 liters (customizable)

Additional functions: stirring, mixing, feeding, loading

Handling materials: chemicals, food, plastics, others, powders, laundry detergent, fertilizers.

What is Vacuum feeder for mixer?

Vacuum feeder for mixer uses vacuum negative pressure as power to achieve fully enclosed automatic material transportation, effectively avoiding dust pollution and material loss. It is suitable for various forms such as powder, granules, pastes, etc. With a high-precision mixer, it can achieve precise mixing with a uniformity of over 98%, meeting the stringent standards of many industries such as food, medicine, and chemicals.

Advantages of Vacuum feeder for mixer

The use of a mixer with a vacuum feeder has significant advantages in modern production, which are mainly reflected in the following aspects.

Achieve automated continuous operation: The combination of a mixer and a vacuum feeder can significantly improve production efficiency and achieve fully automatic feeding.

Improve mixing uniformity: The combined system adopts a closed conveying method to effectively prevent material contamination, moisture absorption or oxidation, and is especially suitable for industries with high hygiene standards such as medicine and food. In addition, the gentle conveying characteristics of the vacuum feeder can reduce material stratification or particle breakage, ensuring the mixing effect.

Improve working environment: The fully enclosed conveying system completely eliminates dust leakage and creates a clean production environment. Compared with traditional conveying equipment, vacuum feeders operate with lower noise and reduce workers' exposure to dust.

Reduce operating costs: The system's closed conveying design can reduce material spillage and residue, and increase material utilization by 5%-10%. Automated feeding reduces the need for manual handling and reduces labor costs.

Meet diverse production needs: The system has wide compatibility and can handle a variety of materials such as powders, granules and lightweight materials. The vacuum pipeline can be flexibly arranged to adapt to different plant space restrictions.

Working principle of Vacuum feeder for mixer

The coordinated operation of vacuum feeder and mixer forms an efficient and precise feeding and mixing system: vacuum feeder uses the negative pressure power generated by rotary vane, cooperates with precision filtration system and PLC automatic control, and realizes closed conveying of materials at a speed of 2-10m/s within 10-30 seconds; when the material level of the mixer is insufficient, the system automatically triggers the feeding program, and the material is transported to the discharge bin through the pipeline and accurately blown into the mixer through 0.4-0.6MPa compressed air. Then the mixer starts the double-screw belt to rotate in reverse to form a three-dimensional mixing field, so that the material reaches a uniformity of more than 98%, completing the whole process from automatic feeding to mixing.

Working time of vacuum feeder with mixer

The following is a reference table of working time of mixer with vacuum feeder system. There will be differences in time for different models. We can customize the appropriate mixing time for you according to your production volume.

|

Working Stage |

Standard Time Range |

Pharmaceutical Industry (Aseptic Type) |

Food Industry (Hygienic Type) |

Chemical Industry (Explosion-Proof Type) |

New Energy (Inert Gas Type) |

|

Single Feeding Cycle |

|||||

|

Vacuum Establishment Time |

8-15s |

10-12s |

8-10s |

12-15s |

10-12s |

|

Material Conveying Time |

15-40s |

20-30s |

15-25s |

30-40s |

25-35s |

|

Discharging Purge Time |

5-8s |

6-8s |

5-6s |

7-8s |

6-7s |

|

Mixing Operation Cycle |

|||||

|

Standard Mixing Time |

3-15min |

5-8min |

3-10min |

8-15min |

10-12min |

|

Homogenization Time |

1-3min |

2-3min |

1-2min |

2-3min |

2-3min |

What materials can be conveyed and mixed by Vacuum feeder for mixer?

The types of materials that can be conveyed by the mixer with a vacuum feeder are very wide, depending on the physical properties of the materials and industry applications.

Powder materials: As the most commonly used type, ordinary powders such as flour and medicinal powder can meet the conveying needs with a 5μm precision standard filter element; while for ultra-fine powders such as graphite powder and pigments with D50≤10μm, a cyclone separator and a PTFE coated filter element need to be installed.

Granular materials: For 3-5mm plastic particles, feed particles, etc., low wind speed conveying is used with a soft landing buffer device to achieve a PET plastic particle breakage rate of <0.01%.

Powder and particle mixing: For materials containing trace additives such as premixed feed, a static mixer is installed to prevent the separation of powder particles due to density differences, ensuring that additives such as vitamins are evenly distributed;

Light and heavy mixing: Light and heavy materials such as carbon black and calcium carbonate, the conveying flow rate is controlled by multi-stage vacuum adjustment to avoid uneven mixing caused by the sedimentation of heavy calcium carbonate.

Nanomaterials: Carbon nanotubes and other materials are transported through low shear, and the agglomeration rate can be controlled below 3%;

Biological preparations: Vaccines, enzyme preparations, etc. use aseptic conveying systems with SIP sterilization functions, which meet GMP aseptic requirements;

3D printing powder: Through particle size classification device + humidity control (RH < 15%), the printing accuracy and molding quality of raw materials such as metal powders are guaranteed.

Mixer with vacuum feeder supports customized solutions

The customized solution of mixer with vacuum feeder can be personalized according to different industries, material characteristics and production needs.

Material customization: It uses medical grade 316L stainless steel and is mirror polished to meet the production needs of aseptic preparations; for acid and alkali corrosive materials, it can be lined with PTFE or Teflon coating.

Structural customization: The structure has ATEX certified explosion-proof motors and nitrogen protection systems, which are suitable for dust explosion environments; high-temperature equipment uses 200℃ temperature-resistant seals and cooling jackets to meet the processing of heat-sensitive materials, and the position of the discharge port can be changed at will according to your production scenario.

Intelligent control: Access the MES system through the OPC UA/MQTT protocol to support IoT data interaction; the AI optimization system automatically adjusts the mixing parameters with the help of machine learning.

Cleaning solution: The pharmaceutical industry uses CIP three-dimensional rotating spray ball + online pH monitoring; the clamp-type quick-release structure is configured for multiple production scenarios, and the disassembly is completed within 5 minutes.

Special conveying solution: The nanomaterial conveying adopts a low-shear Venturi structure to prevent particle breakage; the flammable solvent scene is equipped with an inert gas circulation system; the viscous paste such as chocolate slurry is fed through a heated pipe combined with a spiral auxiliary feed to ensure smooth conveying.

Full-scenario solution: From material selection to intelligent control, modular customization is used to meet the special needs of the pharmaceutical, food, chemical and other industries, and to achieve safety, accuracy and efficiency improvement in the material handling process.

Vacuum feeder for mixer manufacturer

Dahan Machinery Co., Ltd. has focused on the production, manufacturing and technical services of vacuum feeders, vacuum suction machines, mixers, conveyors, screening machines and other equipment for more than ten years. The product is suitable for various mixers and can convey a variety of powders and granular materials such as flour and medicinal powder. Made of 316L stainless steel, the part in contact with the material is mirror polished, meeting the strict hygiene standards of the food and pharmaceutical industries. Its vacuum feeder has the advantages of high speed, energy saving, low noise and environmental protection. When used with a mixer, it can greatly improve the efficiency and quality of material mixing. It has reached long-term cooperation with many domestic and foreign companies.

The solution of the mixer with a vacuum feeder provides a high-speed, environmentally friendly and precise material mixing and conveying method for many industries. Through customized design, it can meet the special needs of different industries and different materials, improve production efficiency, ensure product quality and reduce production costs.