Powder Sieving Machine

A powder sieving machine is a general-purpose screening device used for grading, removing impurities, and purifying powdered materials. It uses vibration, airflow, or other propulsion methods and is widely used in industries such as food, pharmaceuticals, chemicals, and building materials. Amplitude: 0.2-3mm Frequency: 300-3600 times/minute Motor Power: 0.18kW-4kW Material: Plastic, carbon steel, stainless steel, etc.

What is a powder sieving machine?

A powder sieving machine is a type of screening equipment used to sieve powders. Common types include vibrating screens, airflow screens, and drum screens. They are used to sieve powders with uneven particle size and impurities. They effectively address powder sieving challenges that other sieving machines struggle with and are widely used in powder handling and processing across various industries. They lay the foundation for downstream operations and improve product quality and production efficiency.

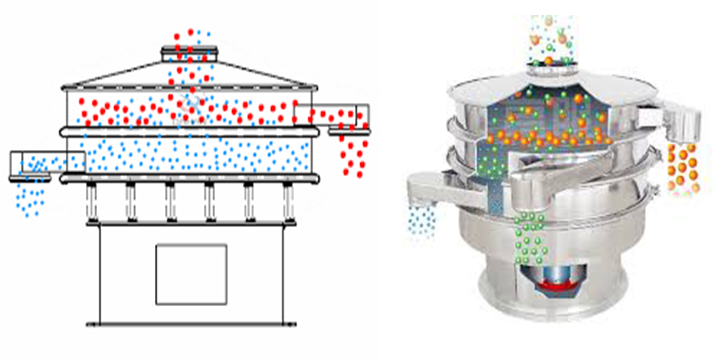

How does a powder sieving machine work?

The sieving and impurity removal process of a powder sieving machine is primarily controlled by the screen mesh. Depending on the size of the screen mesh, powder can be separated and graded based on particle size or impurities can be removed. Powder screening machines use external forces such as vibration or centrifugal force to drive the screen surface to influence the material (or directly influence the material), accelerating material separation efficiency. They can also specifically address material screening challenges such as sticking, clogging, and flyaways. Compared to traditional manual powder screening, powder screening machines can exponentially improve screening efficiency and accuracy, solving screening challenges that cannot be addressed by manual screening, reducing labor costs, and effectively improving production efficiency and product quality.

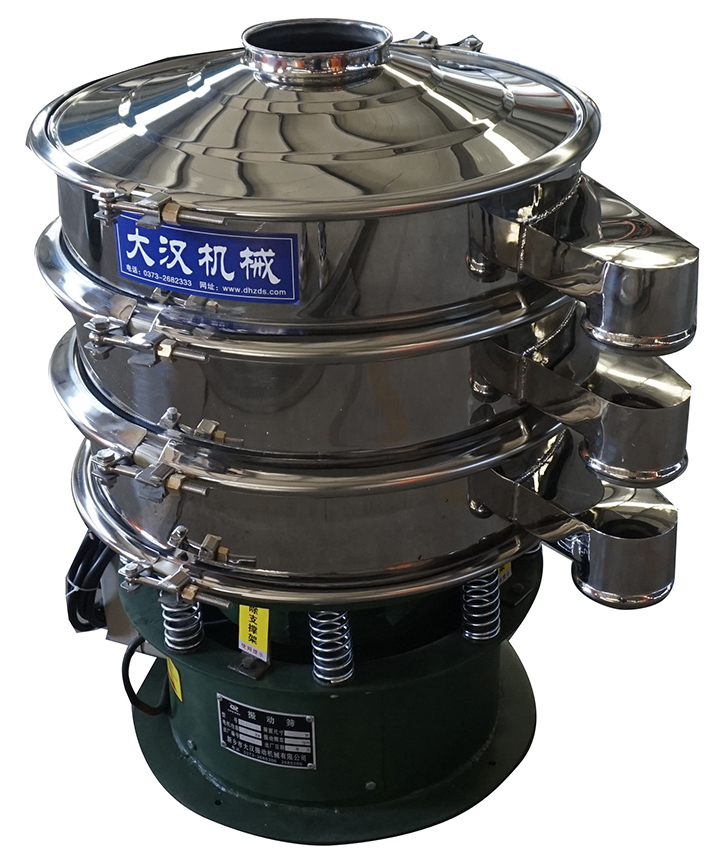

What is the structure of powder sieving machine?

Vibration Equipment: The vibration motor provides the vibration source, along with the eccentric shaft, coupling, and reducer.

Screening Equipment: The screen (the core component of the screening process) and the screen box.

Inlet and outlet: Components used to move materials in and out of the equipment.

Control System: A timer, speed regulator, and other control systems. Parameters such as screening time, vibration frequency, and amplitude can be set.

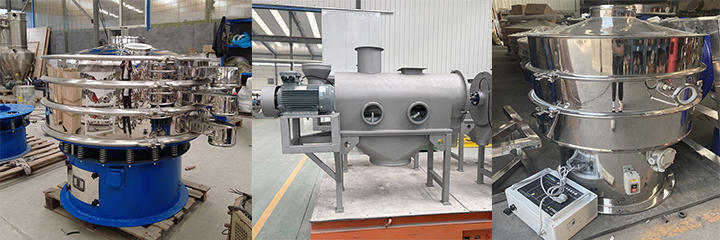

What are the types and advantages of powder sieving machine?

Fine powders have poor flowability and tend to accumulate; coarser powders have better flowability but may result in incomplete screening; ultrafine powders (e.g., above 600 mesh) are affected by air resistance and intermolecular forces, resulting in slow sieving; lightweight powders tend to fly; and dry powders are susceptible to electrostatic adsorption, making sieving difficult. The following types of screening equipment can address these issues:

Rotary Vibrating Screens: Use three-dimensional vibration to effectively disperse powder agglomerates. By adjusting the eccentric weight, the powder remains on the sieve surface longer, reducing the chance of agglomerates being discharged before they are broken up, ensuring accurate grading.

These screens are suitable for conventional powders with medium flowability and low viscosity, such as flour, milk powder, and resin powder.

Ultrasonic Vibrating Screens: Use high-frequency, low-amplitude ultrasonic vibrations (approximately 40kHz) to instantly break up agglomerates and dislodge fine powder clogged in the sieve openings, improving clogging efficiency by 3-5 times compared to conventional vibrating screens. They also effectively address the problem of lightweight ultrafine powders easily flying, ensuring the proper flow of fine powder through the sieve and improving screening accuracy.

Suitable for ultrafine powders, sticky powders, and powders with static electricity, such as nano-ceramic powder, battery cathode material powder, and starch.

Centrifugal screening machines: High-speed rotating blades generate centrifugal force to break up lumps, prevent agglomerates from clogging the screen surface, and address the problem of entanglement of fiber impurities.

Suitable for highly agglomerated, fibrous, or slightly moist powders, such as starch, chemical fiber raw material powder, traditional Chinese medicine residue powder, and cassava flour.

What are the applications of powder sieving machine?

Food industry (screening and removing impurities from flour, milk powder, and spice powder); pharmaceutical and health product industry (screening and removing impurities from medicinal powders and protein powder); chemical and new materials industry (screening and removing impurities from coating powder, battery cathode and negative material powder, and laundry detergent); building materials and metallurgy industry (screening and removing impurities from cement powder and metal powder); and powder screening in other industries.