Precious Metal Reaction Vessel

Volume range: 50mL-5000L

Working temperature: -100℃ to 600℃

Working pressure: Vacuum to 10MPa

Heating method: Electric heating, oil bath, microwave assisted, etc.

Stirring speed: 0-1500rpm adjustable

Control accuracy: ±0.5℃ (temperature), ±0.01MPa (pressure)

What is a Precious Metal Reaction Vessel?

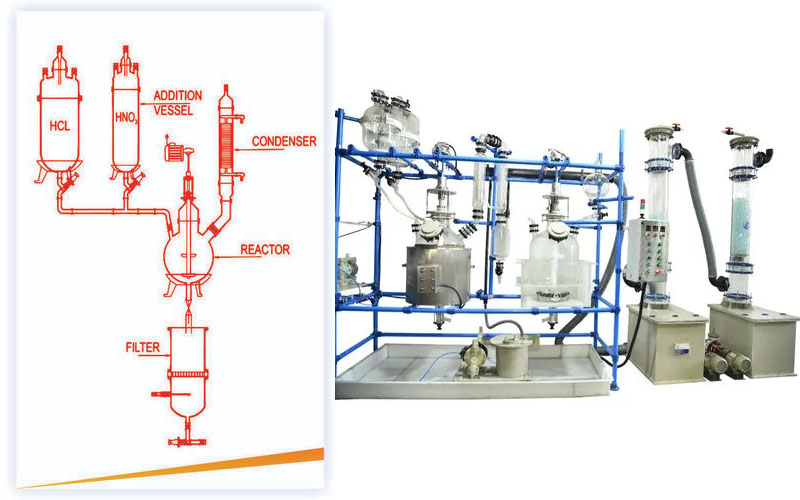

A Precious Metal Reaction Vessel is a reaction vessel used in chemical processing systems for refining, dissolving and purifying gold and platinum group metals (platinum, palladium, rhodium, etc.). It has the characteristics of strong acid resistance, high temperature resistance, high sealing, etc., which can greatly reduce the loss of precious metals (loss rate <0.5%). It is widely used in gold refining (aqua regia dissolution), platinum group metal recovery, and catalyst production. It supports extreme reaction conditions from -80℃ to 500℃. Common materials include titanium alloy (strong acid and alkali resistance), high borosilicate glass (temperature resistance -80°C~300°C) and nickel-based alloy coating (alkali corrosion resistance) to ensure safety and long life.

What are the functions of Precious Metal Reaction Vessel?

Precious Metal Reaction Vessel is an efficient container for the purification, chemical reaction and material synthesis of precious metals such as gold, silver and platinum. It can be used for precious metal purification, chemical reaction control and material synthesis:

Precious metal purification: high-purity metal recovery is achieved through vacuum distillation and filtration separation (such as sand core filtration);

Chemical reaction control: supports high temperature (300℃), low temperature (-80℃) and vacuum environment (-0.098MPa), suitable for catalytic reaction, dissolution and digestion, etc.;

Material synthesis: such as the preparation of precious metal catalysts, the reaction efficiency is optimized by constant temperature stirring. The equipment materials include high borosilicate glass (corrosion resistance), titanium alloy (anti-aqua regia corrosion) and stainless steel frame (enhanced stability)

What are the advantages of Precious Metal Reaction Vessel?

Precious Metal Reaction Vessel has become a high-end reaction equipment with its super corrosion resistance (can withstand strong corrosive media such as aqua regia and hydrofluoric acid), excellent high temperature stability (working temperature 500-600℃, some models reach 1500℃) and ultra-high purity guarantee (meeting electronic grade purity requirements). It uses precious metal materials with catalytic properties such as platinum and palladium, and cooperates with special cladding technology to extend its service life by more than 3 times. It is an ideal choice for precious metal refining, chemical catalysis and other fields, providing reliable protection for high-precision chemical reactions.

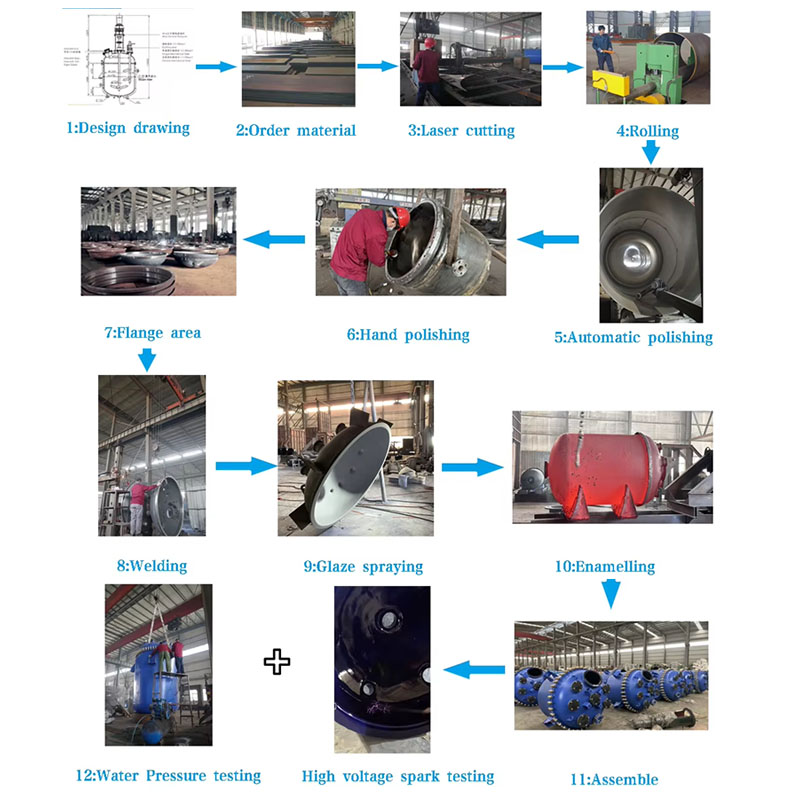

What is the process flow of Precious Metal Reaction Vessel?

The process flow of Precious Metal Reaction Vessel includes raw material preparation, closed reaction system, temperature control and pressure adjustment, reaction process monitoring, product separation and clarity, etc., as follows:

Raw material preparation: high-purity raw material pretreatment

Reaction system closed: inert gas replaces air

Temperature control: accurately heat up to reaction temperature

Pressure regulation: adjust pressure according to reaction requirements

Reaction process monitoring: real-time monitoring of parameters such as pH, temperature, and pressure

Product separation: product separation and purification after the reaction is completed

System cleaning: high-purity solvent cleaning reaction system

What are the applications of Precious Metal Reaction Vessel?

Precious Metal Reaction Vessel is widely used in precious metal refining, chemical catalysis, new energy material preparation and other fields due to its corrosion resistance, high temperature resistance, high sealing and other characteristics.

Precious metal refining and recycling

Purification of gold and platinum group metals (platinum, palladium, rhodium): using aqua regia dissolution, high-pressure digestion and other technologies, high-efficiency separation is achieved under high temperature (500°C) or negative pressure (-0.1MPa) environment, and the loss rate is less than 0.5%.

Photovoltaic module silver recovery: through a multi-stage reactor + filtration system, high-purity silver is extracted from discarded solar panels to improve resource utilization.

Chemical catalysis and synthesis

Catalyst production: precious metals such as platinum and palladium have catalytic effects themselves, and reactors can be used to prepare high-efficiency catalysts in the petrochemical and pharmaceutical industries.

Organic synthesis: such as pharmaceutical intermediates and high-end material synthesis, it needs to be carried out under the protection of inert gas (nitrogen) to avoid oxidation reactions.

New energy and environmental protection field

Lithium battery material preparation: used to synthesize high-purity electrode materials (such as ternary precursors) to ensure uniform distribution of metal ions.

Solid waste treatment: digest heavy metals in electronic waste and industrial sludge to achieve harmlessness and resource utilization.

Scientific research and laboratory analysis

Sample pretreatment: used to quickly digest insoluble samples (such as rare earths, food pesticide residues) in atomic absorption spectroscopy (AAS), plasma emission spectroscopy (ICP) and other analyses.

Hydrothermal synthesis: preparation of nanomaterials, single crystal growth, withstanding 10MPa high pressure and strong acid environment

Precious Metal Reaction Vessel Manufacturers