Fully automatic liquid packaging machine

Fully automatic liquid packaging machine common models of price ranges from US$3,000 to US$32,000. This equipment is suitable for packaging water-like liquids, viscous liquids, liquids containing particles and some corrosive liquids.

Speed: 1500-2200 bags/hour, high-speed continuous production. Capacity: 100-500ml/bag, customizable 1-30ml or 1-120ml. Film width: suitable for 240/320mm or ≤220mm and other specifications. Power supply: 220V/380V, 1.5-12kW, wide scene adaptation. Applicable bag type: back-sealed bag, three-side sealed bag, four-side sealed bag, special-shaped bag. Function: UV sterilization, date printing, automatic deviation correction and anti-drip.

What is Fully automatic liquid packaging machine?

Fully automatic liquid packaging machineis an automated equipment that integrates filling, bag making, sealing, coding, cutting and other functions. It is suitable for the packaging needs of water-like liquids, viscous liquids, liquids containing particles and some corrosive liquids. Compared with traditional semi-automatic filling or manual packaging methods, the equipment has significant advantages in speed, precision, hygiene and labor costs. Depending on the machine model, the packaging speed is generally 30-80 bags/minute, and the high-speed model can reach more than 100 bags/minute, and the daily output can reach 20,000-60,000 bags. Depending on the equipment configuration and production capacity, the price of common models on the market ranges from US$3,000 to US$32,000. The price varies depending on the equipment configuration, packaging requirements, degree of automation and brand differences.

What are the product features of Fully automatic liquid packaging machine?

Fully automatic liquid packaging machine has core advantages such as highly integrated automation, wide material adaptability, precise metering system, as well as intelligent features such as intelligent control, flexible customization, reliable and safe design:

Highly integrated automation: It integrates automatic filling, sealing, bag cutting and metering, and fully automates the entire process from raw materials to finished product output, greatly improving production efficiency and reducing labor costs.

Wide material adaptability: It is suitable for a variety of liquid materials, such as beverages, soy sauce, edible oil, dairy products, sauces, etc., to meet the production needs of different industries.

Precise metering system: It adopts advanced sensors and metering technology, with high packaging accuracy and small error, effectively avoiding material waste and ensuring the same amount of product in each bag.

Intelligent control system: It uses PLC control system and touch operation interface, with stable operation and easy operation, and supports one-button start, fault alarm, automatic shutdown and other functions.

Flexible customization capability: It is suitable for a variety of bag types, supports customization of packaging shape, size and material, and meets diversified production needs.

Reliable and safe design: The whole machine has a reasonable structure, small footprint, stainless steel material, meets food hygiene standards, advanced sealing technology, easy maintenance and cleaning, and ensures product quality and safety.

What types of liquids are suitable for Fully automatic liquid packaging machine?

Fully automatic liquid packaging machine has strong liquid adaptability, including but not limited to water-like liquids, high-viscosity liquids, liquids containing particles, corrosive liquids, etc.

Water-like liquids: such as pure water, soy sauce, vinegar, juice, milk, plant beverages, coffee liquid, herbal tea, liquid sauce, etc.;

High-viscosity liquids: such as honey, shampoo, lubricating oil, jam, sesame paste, mayonnaise, detergent, glass glue, conditioner, gel, etc.;

Liquids containing particles: such as eight-treasure porridge, fruit yogurt, seasoning sauce, salad dressing, coconut fruit drinks, canned porridge, kimchi soup, jelly drinks, etc.;

Corrosive liquids: such as disinfectant, pesticide liquid, detergent, 84 disinfectant, descaling agent, industrial cleaning fluid, acid and alkali solution, alcohol liquid, etc.

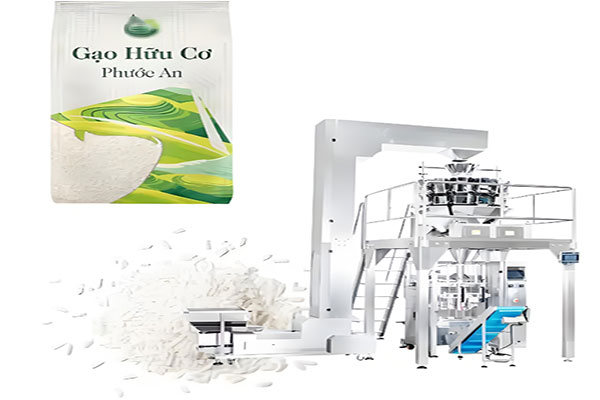

What are the structural components of the Fully automatic liquid packaging machine?

The Fully automatic liquid packaging machine is made of stainless steel, which is safe, durable and easy to clean. There is a distributor on the top, which can accurately distribute materials according to the set quantity; it is equipped with an English control panel and is easy to operate. The middle part is the core part of the packaging machine, which is connected to the distributor and is responsible for sealing and packaging the product. There are two sturdy and reliable machine connection ports. The heat sealing device is configured at the bottom, which can quickly and firmly seal. The bottom of the machine is equipped with universal wheels, which are flexible to move. The various parts work together to efficiently complete the large-scale packaging of liquid products.

What are the technical parameters of the Fully automatic liquid packaging machine?

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

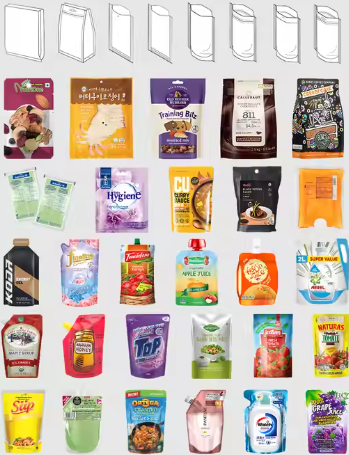

How many bag types can the Fully automatic liquid packaging machine adapt to?

Fully automatic liquid packaging machine can realize automatic forming and filling of various bag types, such as:

Conventional bag type support: compatible with three-side sealed bags, four-side sealed bags, stand-up bags, pillow bags, suitable for most standard packaging needs.

High-end bag type adaptation: supports diversified packaging forms such as self-supporting bags, special-shaped bags, zipper bags, bags with nozzles, etc., to meet the appearance and functional requirements of mid-to-high-end liquid products.

Easy bag type switching: the bag type can be quickly switched by replacing the bag maker and sealing components, which is suitable for flexible production of multiple varieties and small batches.

Complete additional functions: optional punching, hanging hole punching, easy tearing, easy tearing line and other functions can be used to improve the practicality of the bag and consumer experience.

Packaging sample display of Fully automatic liquid packaging machine

What is the price reference of Fully automatic liquid packaging machine?

The price of a fully automatic liquid packaging machine is usually between $3,000 and $32,000. The specific price depends on the equipment specifications, functional configuration and production capacity. The following is an analysis of the price range and core parameters of different types of equipment:

Basic liquid packaging machine: The price is about $3,000-8,000 per unit, suitable for small-scale production or laboratory scenarios. The equipment usually supports small-volume liquid packaging, has basic automatic metering and sealing functions, compact structure and simple operation.

Mid-range multi-functional equipment: The price is about $10,000-20,000 per unit, suitable for food, daily chemicals and other industries. The equipment is equipped with a more advanced control system (such as PLC), a high-precision metering device (accuracy can reach ±1%), supports multi-specification packaging (50-500ml), and has higher production efficiency (2,000-3,000 bags per hour). Some models also have photoelectric tracking, automatic deviation correction and other functions.

High-end customized equipment: The price can reach $20,000-32,000 per unit, suitable for high-viscosity liquids or large-scale production lines. The equipment supports large-volume filling (100-1000ml), higher precision (±0.5%), faster production speed (more than 4000 bottles per hour), equipped with servo motor drive, automatic feedback system, etc., and can customize special functions according to customer needs (such as anti-drip, aseptic filling, etc.).

What are the industry applications of fully automatic liquid packaging machine?

Fully automatic liquid packaging machines are widely used in many industries such as food, daily chemicals, medicine, and chemicals, as follows:

Food and beverage industry: used for filling and packaging of juice, yogurt, milk, condiments (soy sauce, vinegar, cooking wine, etc.), and beverages (mineral water, soda, functional drinks). Its efficient bag making, quantitative filling and sealing technology can meet the diverse needs from 100ml small bags to 200L large capacity, and supports a variety of sealing forms such as back sealing and side sealing to ensure product hygiene and sealing.

Daily chemical and pharmaceutical industry: In the field of daily chemical, creams, lotions, shampoos and other pastes or liquid products can be packaged; in the field of medicine, aseptic packaging technology is used to accurately fill liquid medicines, oral liquids, injections, etc. to meet the high standards of drug production.

Chemical and agricultural fields: Suitable for the packaging of liquid products such as pesticides, fertilizers, and foliar fertilizers. Its corrosion-resistant materials and precise metering systems can adapt to the special properties of chemical products, and support customized design to adapt to different packaging specifications.

Advantages of our factory in manufacturing Fully automatic liquid packaging machine

Our factory has advantages in manufacturing Fully automatic liquid packaging machine, such as one-stop service, modular design, and cost optimization:

One-stop service: Provide full-process services from solution design, equipment customization, on-site installation to after-sales maintenance.

Technology accumulation: With 20 years of experience in the research and development of vibrating screens and packaging machinery, we have mastered core technologies such as direct heat sealing and cutting, and multi-row packaging;

Modular design: Through the standardized component library, equipment transformation can be completed within 72 hours to meet the personalized needs of customers;

Cost optimization: The localized supply chain reduces the cost of key components by 15%-20%, and provides a 3-year warranty and lifetime maintenance services.