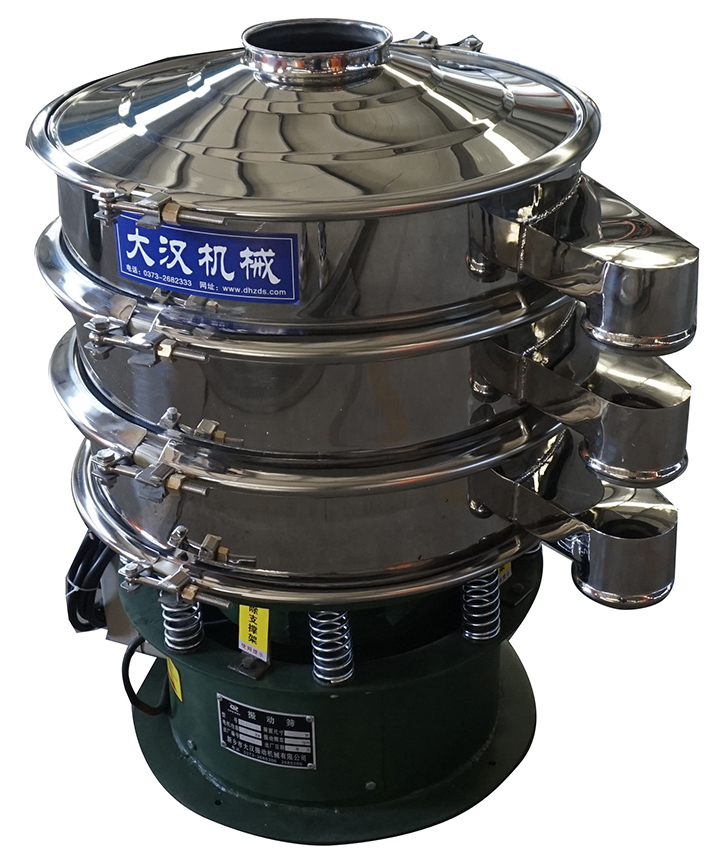

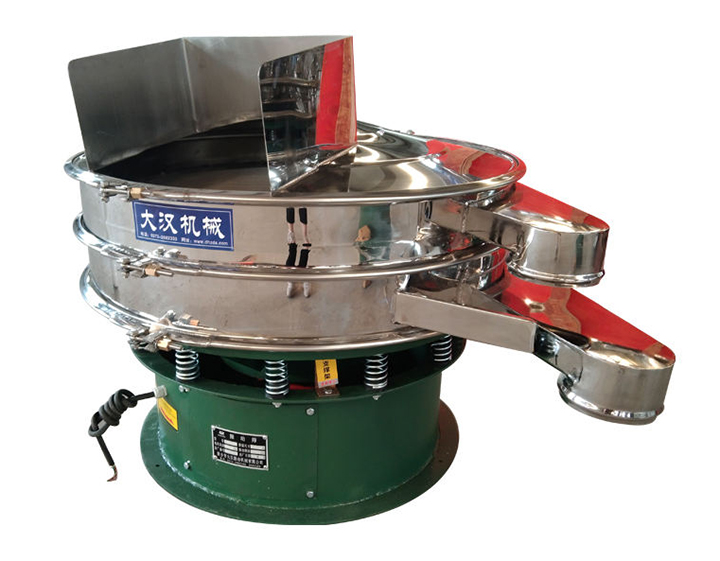

Food Sieving Machine

Compared to ordinary industrial screeners, food sieving machine differ primarily in their material safety and ease of cleaning. They classify, remove impurities, filter, or separate food ingredients or finished products, ensuring they remain contaminated during processing while also improving product purity and uniformity. Material: All contacting parts are made of food-grade stainless steel. Screening accuracy: 0.1-30mm Amplitude: 2-8mm Number of screen layers: 1-5 Feed particle size: Approximately 80-600 mesh

What is a food sieving machine?

Food sieving machines are critical equipment for ensuring product quality and safety in food processing. Their core lies in their materials and structural design, which comply with food hygiene standards, as well as their efficient and precise screening capabilities. By grading, removing impurities, and filtering materials, they not only improve food purity and consistency but also reduce contamination risks during production. Widely applicable in a variety of industries, including grains and oils, fruits and vegetables, dairy products, and snack foods, they are a crucial step in achieving industrialized and standardized food production.

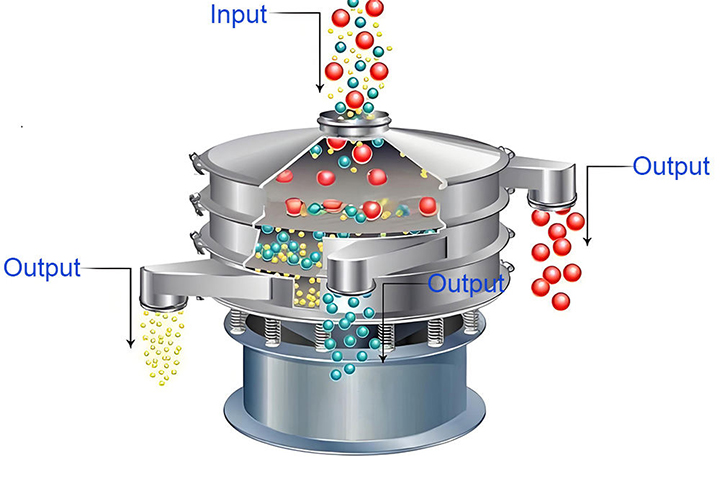

How does a food sieving machine work?

A food screening machine uses a vibrating motor to generate vibration, which, combined with the screen's ability to control particle size, acts on the food material being processed. This power source accelerates material separation and grading efficiency while also improving screening accuracy. The screen apertures limit material penetration, preventing particles larger than the aperture from passing through and remaining on the screen surface. Materials smaller than the apertures pass through the apertures and proceed to the next screening stage or to the bottom layer. The material is discharged through corresponding discharge ports, yielding different particle size grades.

What is the structure of a food sieving machine?

Screen body: The screen frame supports the screen; the screen is the core component of the screening process.

Vibrating motor: Provides the power source, driving the screen body to vibrate.

Inlet and outlet: The device through which material enters and exits the machine. Multi-stage screening systems have multiple outlets.

Frame: Supports the entire machine, ensuring stable operation.

Shock absorber: Absorbs vibration forces, minimizing the negative effects of vibration on the equipment.

What are the advantages of a food sieving machine?

The core advantage of food screening machines is that they improve product quality stability and reduce production costs through efficient and precise screening, while ensuring food hygiene and safety. These machines are also compatible with industrialized and automated production, making them key equipment for ensuring quality control in modern food processing.

Safe and easy-to-clean materials: All material-contacting components are made of food-grade 304/316 stainless steel and food-grade silicone. The screen body and mesh are often quick-release, allowing for quick removal for manual cleaning or compatibility with CIP systems.

High screening efficiency and precision: The multi-layer mesh design enables multiple levels of separation in one operation, reducing process steps and improving screening efficiency. A variety of aperture sizes are available, enabling precise screening of materials ranging from micron-sized fine powders to centimeter-sized particles.

Large throughput: Vibration and rotary vibration ensure rapid material distribution and flow across the screen surface, preventing accumulation. A single unit can process several to tens of tons of material per hour, meeting the needs of large-scale production lines.

Strong Adaptability: By adjusting parameters such as vibration frequency, amplitude, and screen angle, the machine can adapt to different material characteristics (such as dry powders, wet granules, and sticky materials), ensuring stable screening efficiency.

What are the parameters of a food sieving machine?

| 型 号 | DH-600 | DH-800 | DH-1000 | DH-1200 | DH-1500 | DH-1800 | DH-2000 |

| 直径mm | Φ600 | Φ800 | Φ1000 | Φ1200 | Φ1500 | Φ1800 | Φ2000 |

| 筛网面积m | 0.24 | 0.45 | 0.67 | 1.0 | 1.6 | 2.43 | 3.01 |

| 筛网规格(目) | 2-500 | ||||||

| 进料粒度mm | <Φ10 | <Φ15 | <Φ20 | <Φ30 | |||

| 振次rpm | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| 有效筛面直mm | Φ560 | Φ760 | Φ930 | Φ1130 | Φ1430 | Φ1760 | Φ1960 |

| 1-5 | |||||||

| 功率Kw | 0.25 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 |

What are the applications of food sieving machine?

Food sieving machines are widely used in the food processing industry to screen materials to ensure food quality and production efficiency: food and cereal processing (screening wheat, corn, oatmeal, etc.), powder and baking ingredients (screening flour, starch, powdered sugar, etc.), snack foods (screening nuts, dried fruits, candies, potato chips, etc.), condiments and additives (screening to remove salt, spice powder and powder additives, etc.), fruit and vegetable processing (screening fruit and vegetable raw materials, fruit and vegetable powder, jam and puree) and other fields that require food material screening.