High speed mixer

A high speed mixer is a mechanical device that uses a high-speed rotating stirring device to achieve rapid and uniform mixing of materials. Its core feature is that it uses a high speed (usually 500-3000 rpm) and a specially designed stirring structure to complete the mixing, dispersion, homogenization or modification of materials in a short time.

What is a high speed mixer?

A high speed mixer is an industrial equipment used to quickly and evenly mix a variety of ingredients. It is commonly used in plastics, chemicals, pharmaceuticals, food and other industries. It is mainly used for the rapid and uniform mixing of powders and powders, powders and liquids. It uses a high-speed rotating stirring device (such as a paddle, a spiral ribbon or a dispersion disk) to produce strong shear, impact and dispersion effects, so that the ingredients can be evenly mixed in a short time. Its core features are fast mixing speed, high efficiency and good mixing uniformity. In production, it is mostly used for premixing or mixing materials such as resins, plastic additives, masterbatches, PVC dry blends, etc.

The difference between high speed mixer and other mixing equipment

The following is a comparative analysis between high speed mixer and several common mixing equipment, covering their working principles, scope of application, mixing speed, energy consumption, mixing uniformity and other aspects:

1. High Speed Mixer vs High Shear Mixer

| Project | High-speed mixer | High-shear mixer |

| Image |

|

|

| Working principle | Use high-speed rotating stirring blades to throw, shear and centrifugally mix materials | Use rotor/stator system to generate high shear force for microscopic dispersion and mixing of materials |

| Processing state | Suitable for dry mixing of powders or small amounts of liquids | Mostly used for emulsification and dispersion of liquid-liquid and liquid-solid systems |

| Mixing fineness | Generally macro-uniform mixing | Can achieve micro-level dispersion and homogenization |

| Typical applications | Plastic dry mixing, powder premixing | Cosmetics, emulsions, pharmaceutical preparations, adhesives, etc. |

| Energy consumption | Medium to high | High (strong shear force) |

| Viscosity adaptability | Moderate | Suitable for medium and high viscosity systems |

Summary: High-shear mixers focus on microscopic dispersion and emulsification, while high-speed mixers focus more on rapid mixing of dry materials.

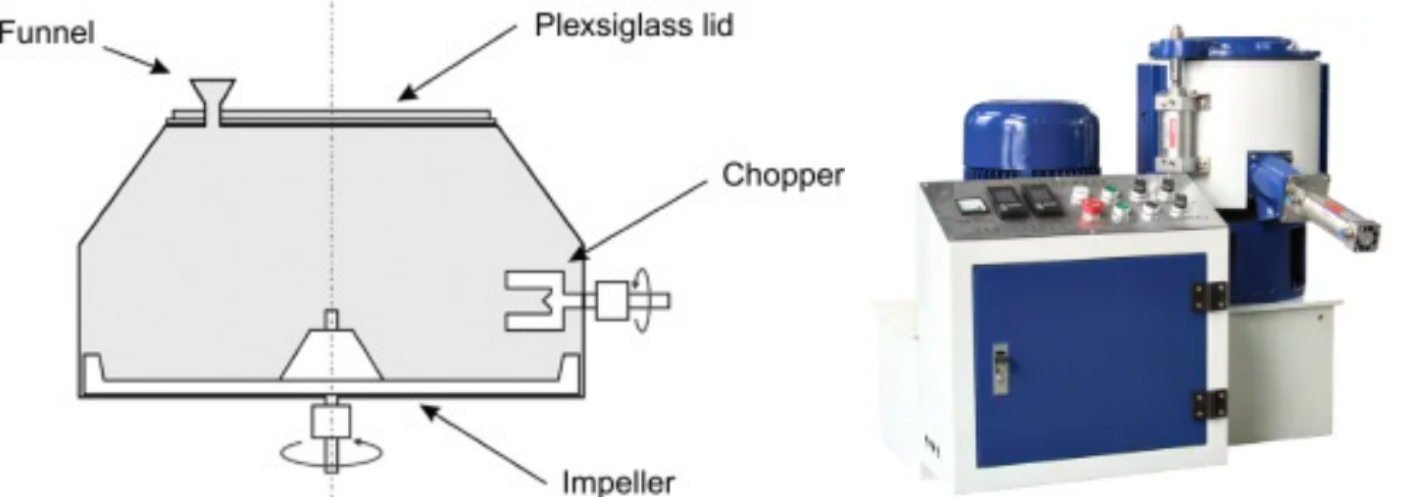

2. High Speed Mixer vs Low Speed Mixer (such as Ribbon Mixer, Paddle Mixer)

| Project | High Speed Mixer | Low Speed Mixer |

| Image |

|

|

| Mixing Speed | High Speed (often hundreds to thousands of rpm) | Low Speed (tens of rpm) |

| Mixing Time | Shorter (1-10 minutes) | Longer (more than 10-30 minutes) |

| Applicable Materials | Powders or granules with low to medium viscosity | Material with high viscosity, or easily broken, or heat-sensitive |

| Temperature Rise | Obvious, some models have heating function | Slower temperature rise, gentle handling |

| Equipment Size | Compact | Can be made into large capacity, suitable for batch production |

| Typical Products | PVC Powder, Masterbatch | Feed, Seasoning, Dry Powder Building Materials, etc. |

Summary: High-speed mixers are suitable for rapid mixing of powders with high efficiency requirements, while low-speed mixers are suitable for materials that are sensitive to heat and shear.

3. High Speed Mixer vs Double Helix Conical Mixer

Summary: Double helix conical mixer is suitable for materials with high mixing accuracy, strong heat sensitivity or fragile materials, while high-speed mixer is more suitable for general and efficient powder premixing.

| Project | High Speed Mixer | Double Helix Conical Mixer |

| Image |

|

|

| Mixing Method | High-speed shearing, throwing, centrifugation | Spiral lifting + self-rotation to form convection |

| Mixing Principle | Strong disturbance rapid mixing | Low speed, high uniformity, no dead angle mixing |

| Applicable materials | Medium fluidity powder/granular material | Fine powder, fragile or heat-sensitive material |

| Mixing uniformity | High (quickly achieved), but slightly fluctuating | Extremely high (suitable for high uniformity requirements) |

| Volume range | Usually small and medium batches | Can be used for large batch mixing (>1000L) |

| Energy consumption | High | Low |

| Typical applications | Plastic raw material mixing, color powder dry mixing | Medicine, food, chemical fine powder mixing |

Overall summary

| Comparison items | High-speed mixer | High-shear mixer | Low-speed mixer | Double-helix cone mixer |

| Mixing speed | High | Extremely high speed (local) | Low speed | Low speed |

| Mixing efficiency | High | High (fine) | Medium | Low to medium |

| Mixing uniformity | High | Extremely high | High | Extremely high |

| Energy consumption | Medium to high | High | Low | Low |

| Applicable materials | Dry powder/granules | Liquid/paste/emulsion | Viscous/brittle/easy to agglomerate materials | Thermosensitive/fragile/ultrafine powders |

| Technological features | Fast speed, suitable for premixing | Dispersion, emulsification, refinement | Gentle mixing, large output | High-precision mixing, no thermal impact |

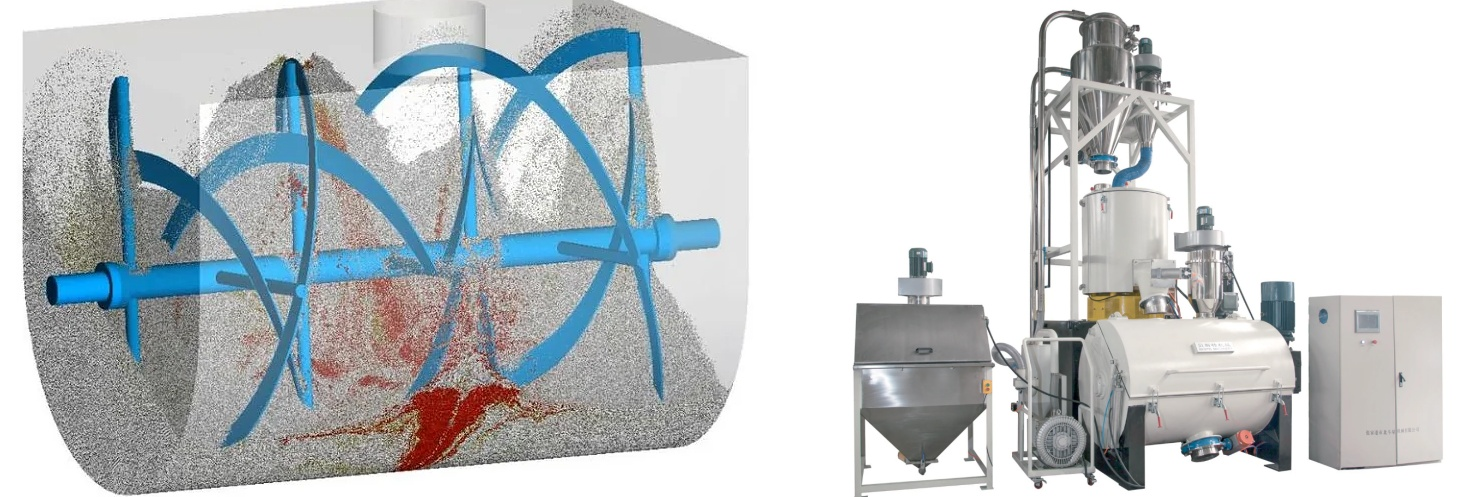

Working principle of high-speed mixer

When the high-speed mixer is working, the motor drives the main shaft to rotate through the belt wheel and the reduction box, thereby making the rotating blades rotate at high speed. The rotating blades use the friction between the surface and the material and the thrust of the side to the material to make the material move along the tangent of the impeller. At the same time, due to the action of centrifugal force, the material is thrown to the inner wall of the mixing chamber and rises along the wall. When it rises to a certain height, due to gravity, the material falls back to the center of the impeller, and then is thrown up again. The combination of this upward motion and tangential motion makes the material actually in a continuous spiral up and down motion state.

Structure of high-speed mixer

Mixing container (barrel): used to hold the material to be mixed, usually made of stainless steel; the inner wall is smooth and easy to clean.

Stirring blade (high-speed impeller): installed on the main shaft, through the high-speed rotation of the motor, it produces strong shear and convection effects to achieve rapid mixing.

Motor (main drive): provides power to drive the stirring paddle to operate; the power size is determined by the equipment capacity and material properties.

Reducer/belt drive system: controls the stirring speed, and some equipment uses variable frequency speed regulation.

Heating device (optional): Some high-speed mixers are equipped with jackets or electric heating systems to preheat or dry the materials.

Discharging device: located at the bottom or side of the barrel, used to quickly discharge the material after mixing is completed, such as pneumatic valves or manual flip covers.

Control system: including start button, timer, temperature controller, emergency stop button, etc., used to operate and monitor the operating status of the equipment.

Safety protection devices: such as interlock switches, explosion-proof motors, safety covers, etc., to ensure personal and equipment safety during operation.

What are the advantages of high-speed mixers?

High-speed mixing: The materials are evenly mixed in a short time through the high-speed rotating stirring paddle. The mixing time is usually between a few seconds and a few minutes.

Efficient and uniform: Through strong stirring and dispersion, the ingredients are mixed evenly, which is suitable for production requiring high uniformity.

Efficient dispersion: It can effectively disperse powder into liquid, or evenly mix materials of various components.

Versatility: Some high-speed mixers can also be equipped with disintegration tools to achieve multiple functions such as mixing, granulation and crushing. At the same time, auxiliary devices such as heating, cooling, and vacuum can be configured according to process requirements.

Wide application: High-speed mixers are widely used in chemical, food, medicine, plastics, building materials, feed and other industries for mixing powders and powders, powders and liquids, and viscous materials.

Specifications of high-speed mixer

| Model | Total volume (L) | Effective volume (L) | Motor power (kW) | Spindle speed (rpm) | Applicable material examples |

| SHR-10A | 10 | 7 | 2.2 | 1440 | PVC formula powder for experiment |

| SHR-50A | 50 | 35 | 5.5 | 1440 | Plastic modification additives |

| SHR-100A | 100 | 75 | 7.5 | 1440 | PVC resin powder, pigment |

| SHR-200A | 200 | 150 | 11 | 1440 | Masterbatch premix |

| SHR-300A | 300 | 225 | 14 | 1440 | Stabilizer + filler mix |

| SHR-500A | 500 | 375 | 30 | 960–1440 | PE/PP masterbatch mix |

| SHR-1000 A | 1000 | 750 | 55 | 960–1440 | Large batch powder mixing |

Application of high-speed mixer

Due to its high-efficiency mixing characteristics, high speed mixers are widely used in the chemical, food, pharmaceutical and plastic industries. Through the strong shear force and convection generated by high-speed rotating blades, pigments, coatings, powders, food additives (such as milk powder and seasonings), plastic masterbatches and other materials are quickly and evenly mixed. They are especially good at dispersing ingredients that are easy to agglomerate (such as resin additives and metal powders). The uniformity of the mixture can reach more than 98% within 5-10 minutes, meeting the relevant standards, food hygiene requirements and the high-efficiency requirements of industrial continuous production.

High speed mixer manufacturers

Dahan Machinery (Xinxiang Dahan Vibration Machinery Co., Ltd.) is a company specializing in the manufacture of vibration screening equipment, conveying equipment and mixing equipment, located in Xinxiang City, Henan Province, China. The high-speed mixers produced by the company are widely used in the chemical, food, pharmaceutical, metallurgical, building materials and other industries, and are suitable for the mixing process of powders, particles, additives and other materials.

The high-speed mixers (such as trough mixers, vertical mixers, etc.) provided by Dahan have the following features:

Efficient mixing: using advanced design to ensure uniform mixing of materials and shorten mixing time.

Versatility: suitable for mixing dry powder, wet materials, and materials containing trace additives to meet the needs of various industries.

Durability: The equipment is made of high-quality materials such as stainless steel, which is corrosion-resistant, easy to clean, and meets the hygiene standards of the food and pharmaceutical industries.

Customization: Different models (such as 10L to 1000L) and customized configurations can be provided according to customer needs.

If you need more detailed product models and quotations, please provide more specific requirements, and we can further optimize the answer for you!