Electronic component packaging machine

Wednesday January-14 2026 17:56:43

Electronic component packaging machine can seal various electronic components to prevent damage from moisture, static electricity, and impacts during transportation and storage. High-speed models can complete 50-200 packaging units per minute, while medium- and low-speed models can complete 10-50 packaging units per minute. Mechanized operation not only speeds up the packaging process but also reduces human error and improves the overall efficiency of the production line.

How do electronic component packaging machines package electronic components?

Electronic component packaging machines automatically feed electronic components into the packaging area via a feeding system. Then, a robotic arm or roller system places the components into packaging bags, which are finally sealed. Common packaging methods include tape packaging, bagging, and pallet packaging. In tape packaging, components are neatly arranged on tape and secured with a transparent cover film for easy automatic placement by the subsequent pick-and-place machine. In bagging, electronic components are placed in anti-static or moisture-proof bags, and the machine automatically counts, places, seals, and marks them. The entire process is typically controlled by a PLC or computer program, precisely controlling the packaging quantity, speed, and sealing quality to ensure components are not damaged during transportation and storage.

Electronic Component Packaging Machine Functions

Electronic component packaging machines can control the quantity of electronic components per bag according to a set quantity. The machine ensures packaging airtightness through heat sealing or ultrasonic sealing technology. It can print batch numbers, model numbers, production dates, and other information on the packaging bags for easy tracking and management. Advanced packaging machines are also equipped with anti-static, dehumidification, airtightness detection, and abnormal alarm functions to ensure stable packaging quality. Some machines also support multiple packaging modes, such as roll packaging, bag packaging, and pallet packaging, making them adaptable to the packaging needs of different electronic components.

Electronic Component Packaging Machine Types

Electronic component packaging machines are divided into two types based on machine size: fully automatic high-speed packaging machines and small packaging machines. Both types of machines can be equipped with packaging parameters; the following is a comparison of the two types.

Fully automatic high-speed packaging machines use a Z-shaped conveyor to transport electronic components to the packaging location. During operation, parameters such as packaging quantity, sealing mode, and speed are preset via a human-machine interface. The electronic components are then automatically fed, weighed, bagged, and sealed. Packaging capacity can reach 60-120 bags per minute.

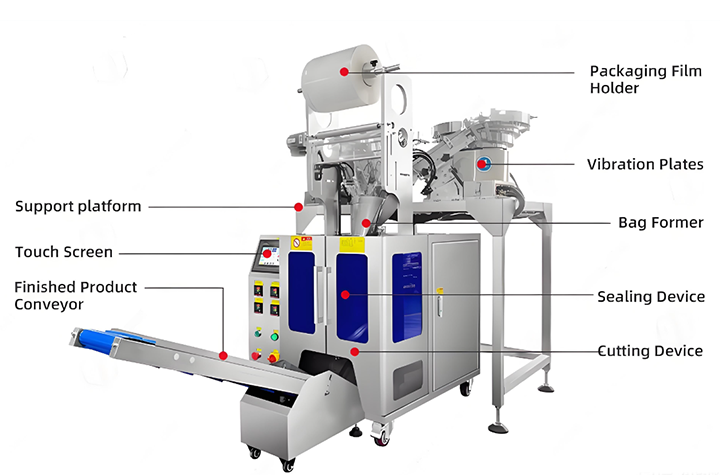

Smaller packaging machines use a short belt conveyor to transport electronic components to the feeding port. The components are then packaged using pre-installed materials, followed by cutting to complete one package. Packaging capacity is approximately 20-40 bags per minute. The machine supports manual adjustment of sealing and cutting parameters and is suitable for factories with limited space.

Materials for Electronic Component Packaging Machines

The packaging materials for electronic component packaging machines are designed to prevent moisture damage to electronic components and to prevent tearing of the packaging bag for sharp components. Common packaging bag materials include anti-static PE bags, aluminum foil moisture-proof bags, transparent PET bags, and nylon composite bags. Antistatic PE bags prevent electrostatic damage to components during packaging and transportation; aluminum foil moisture-proof bags offer moisture and oxidation protection, suitable for storing components susceptible to moisture; transparent PET bags are high-strength, preventing packaging breakage and facilitating visual inspection of electronic components; nylon composite bags offer high abrasion resistance and sealing properties, suitable for long-term storage or transportation.

What electronic components can an electronic component packaging machine package?

An electronic component packaging machine can package resistors, capacitors, inductors, diodes, transistors, integrated circuit chips, transistors, connectors, sensors, etc. For surface-mount components, tape and reel packaging is typically used; for bulk or irregularly shaped components, bag or pallet packaging is suitable. Different models of packaging machines can accommodate components of different sizes, shapes, and weights to prevent damage from squeezing, collisions, or static electricity during packaging.

In the electronic component packaging process, in addition to the packaging machine itself, feeding machines, labeling machines, and testing and inspection equipment are also used. Feeders automatically feed components into the packaging machine, improving efficiency; labeling machines print and affix batch numbers and model information; testing and inspection equipment checks component performance before packaging to ensure shipment quality. Good packaging involves selecting appropriate protective materials based on product size, weight, and transportation environment, while simultaneously using automated packaging machines for sealing, ensuring the electronic components are safe and neatly packaged during transportation.