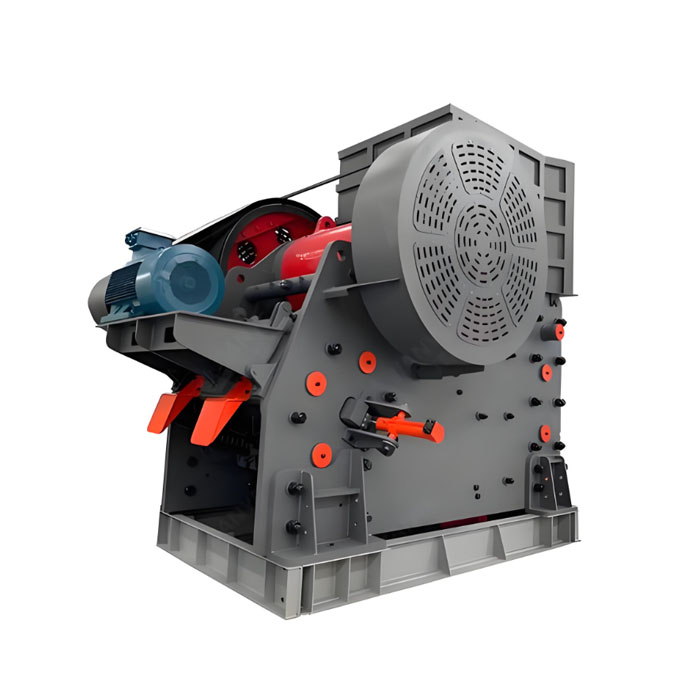

Construction Debris Coarse Crusher

It is used for crushing construction waste with particle size less than 1400mm such as concrete, bricks, asphalt, etc.

Feed size: ≤1400mm

Discharge size: 3-150mm

Processing capacity: 3-680t/h

What is Construction Debris Coarse Crusher?

Construction Debris Coarse Crusher is a construction waste crushing and processing equipment, mainly used for the primary crushing of solid waste such as concrete blocks, bricks, and steel bars in scenes such as demolition projects and road reconstruction. It can crush construction waste such as waste concrete, bricks, and steel bars into recycled aggregates for brick making, roadbed paving, etc., to achieve the "reduction, harmlessness, and resource utilization" treatment goals. The feed particle size is <1400mm, and the finished product particle size is optional from 3 to 50mm, with an hourly output of up to 650 tons.

What are the categories of Construction Debris Coarse Crusher?

Construction Debris Coarse Crusher can be divided into three types: jaw, impact and mobile. You can choose according to the material and crushing process requirements.

Jaw crusher series (PEW/HJ series): suitable for high-hardness materials (such as reinforced concrete), feed size can reach 1100×1200mm, crushing capacity 650t/h

Impact crusher series (PFW series): suitable for medium-hardness materials (such as bricks, concrete), finished product particle shape is good, cubic, suitable for recycled aggregate production

Mobile coarse crushing station (oil-electric dual-purpose type): flexible transfer, suitable for urban demolition sites, integrated crushing, screening, and iron removal functions, to achieve "on-site crushing and on-site utilization"

What types of construction waste can be crushed by Construction Debris Coarse Crusher?

Construction waste has complex composition, mainly including: concrete blocks (such as floor slabs, beam and column fragments), brick and tile waste (red bricks, hollow bricks, ceramic tiles, etc.), steel/metal waste (need to be matched with iron remover), asphalt pavement waste (suitable for road renovation projects), decoration waste (light materials such as gypsum board and wood), etc.

Construction waste of different materials needs to use the appropriate construction waste coarse crusher model to ensure efficient crushing and reduce equipment wear, such as: Concrete blocks: high hardness, need to use jaw crusher or heavy impact crusher; Brick and tile waste: brittle texture, suitable for impact crusher; Asphalt pavement waste: need to be crushed at low temperature to avoid adhesion, it is recommended to use a mobile crushing station with pre-screening; Mixed construction waste (including steel bars): need to be equipped with iron remover to prevent metal from damaging the equipment, it is recommended to use a double-axis shear crusher.

What are the benefits of Construction Debris Coarse Crusher?

Construction Debris Coarse Crusher adopts high-chromium alloy hammer head, which has strong wear resistance and large crushing ratio, and can easily handle construction waste below 1400mm; it is equipped with Siemens PLC touch screen for intelligent control, easy operation, and can automatically adjust the crushing particle size; it is driven by low-speed hydraulics, with low noise and less dust during operation, which fully meets the requirements of urban environmental protection; the crushing chamber structure can be flexibly replaced according to different types of construction waste, and it has strong applicability; the tool supports repair welding and reuse, and the bearing adopts imported sealing technology, which effectively extends the service life of the equipment and reduces maintenance costs.

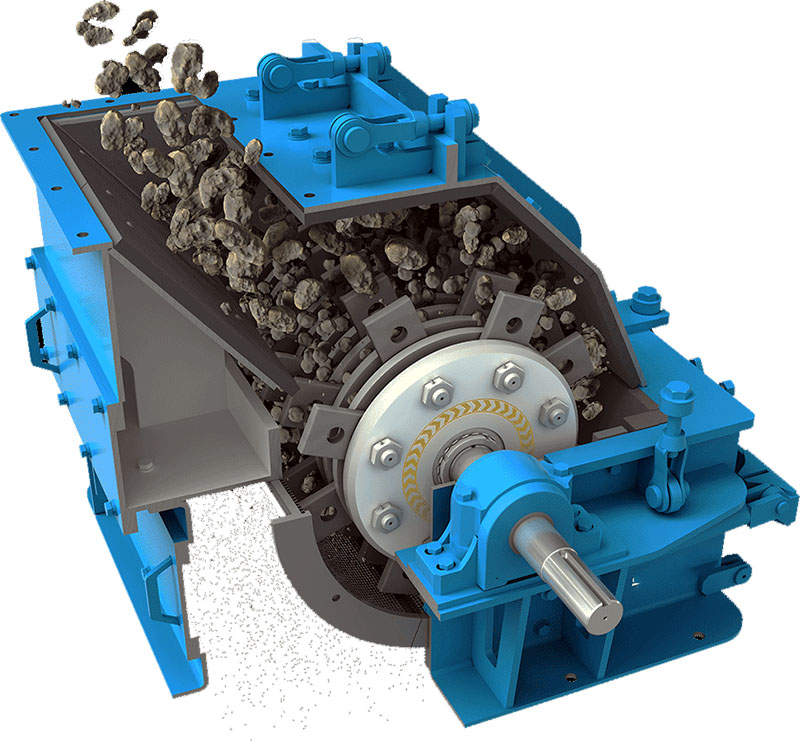

How does the Construction Debris Coarse Crusher work?

When the Construction Debris Coarse Crusher is working, the construction waste is evenly fed into the crushing chamber through the feeder, and is crushed by impact, shearing and extrusion through the high-speed rotating hammer or jaw plate. The construction waste that meets the particle size requirements is discharged through the screen, and the oversized construction waste is returned for secondary crushing, forming a closed-loop cycle.

Construction Debris Coarse Crusher Parameters

| Model | Feed size (mm) | Processing capacity (t/h) | Discharge size (mm) | Motor power (kW) | Equipment weight (t) |

| PCZ-1308 | ≤850 | 100-160 | 3-50 adjustable | 132 | 15.6 |

| ZSSL-69 | ≤100 | 80-160 | 3-30 adjustable | 185-200 | 38 |

| GC series hydraulic | ≤1200 | 50-120 | 10-100 adjustable | 160-220 | 25-40 |

How to choose a suitable Construction Debris Coarse Crusher?

Choose by material hardness: choose jaw crusher for high hardness (concrete); choose impact crusher for medium and low hardness (bricks and tiles).

Choose by production demand: choose fixed type for small scale (<100t/h); choose mobile type for large scale (>200t/h).

Choose by environmental protection requirements: choose low noise + dust removal configuration for urban operation; choose standard model for open field.

Coarse crusher

Coarse crusher Pharmaceutical Materials Coarse Crusher

Pharmaceutical Materials Coarse Crusher

Herbs Coarse Crusher

Herbs Coarse Crusher