Nitrogen oxide treatment equipment

Equipment for treating harmful nitrogen oxides (NOx) in industrial waste gas, converting NOx into harmless nitrogen (N₂) and water (H₂O) using technologies such as selective catalytic reduction (SCR) or non-catalytic reduction (SNCR)

Price: $900-$40,000

Air volume range: 5,000-500,000Nm³/h (can be increased by 50Nm³/h)

Power requirement: 380V/50Hz or customized 460V/60Hz

Catalyst type: honeycomb, plate or corrugated type optional

Are you facing the following troubles?

The nitrogen oxides (NOx) emitted by the factory exceed the standard and it is difficult to meet the environmental protection standards?

Looking for an efficient, stable and economical NOx treatment solution to enhance the green image of the enterprise?

Not satisfied with the existing NOx treatment technology and looking for more advanced solutions?

As a professional Nitrogen oxide treatment equipment manufacturer, we know your needs! We are committed to the research and development and production of high-quality, high-performance Nitrogen oxide treatment equipment to provide your company with a one-stop NOx emission reduction solution.

What is Nitrogen oxide treatment equipment?

Nitrogen oxide treatment equipment is designed to solve the NOx pollution problems generated in various industrial processes, using advanced catalytic reduction technology (such as SCR, SNCR, etc.), it can efficiently treat nitrogen oxide waste gas emitted by various industrial facilities from thermal power plants, chemical plants, cement plants to automobile manufacturing. We provide products of various specifications and models, which can be customized according to the needs of customers in different industries and different emission standards.

Core processing capability: The system has a NOx removal efficiency of more than 95%, which is much higher than the industry average. The NOx concentration in the treated exhaust gas can be reduced to below 50mg/m³, which fully complies with the world's most stringent emission standards such as EU2017/1445, US EPA40CFR60 and China GB13223-2011. The equipment adopts a modular design, with a processing air volume ranging from 5,000Nm³/h to 500,000Nm³/h, and can be flexibly configured according to the actual needs of customers.

What are the categories of Nitrogen oxide treatment equipment?

Selective catalytic reduction (SCR) denitrification system: Ammonia or urea is used as a reducing agent to reduce NOx to harmless nitrogen and water under the action of a catalyst. It has the advantages of high denitrification efficiency, stable operation, and a wide range of applications. It is the current mainstream NOx treatment technology.

Selective non-catalytic reduction (SNCR) denitrification system: The reducing agent is directly injected under high temperature conditions to react with NOx in the flue gas. It has the characteristics of low investment cost and simple installation, and is suitable for the treatment of medium and low concentrations of NOx.

Other innovative NOx treatment technologies: We continue to explore and develop new NOx treatment technologies to meet increasingly stringent environmental protection requirements.

Why choose our Nitrogen oxide treatment equipment?

Ultra-high treatment efficiency and stable operation: The fourth-generation composite catalyst is used, which has an activity that is 40% higher than that of traditional catalysts, and the NOx removal rate is stable at more than 95%; the adaptive control system monitors the exhaust gas flow, temperature and NOx concentration in real time, and automatically optimizes the operating parameters

Significantly reduce operating costs: Low-temperature catalytic technology reduces the reaction temperature to 180°C, which is more than 30% energy-saving than the traditional SCR system; the intelligent ammonia injection system reduces the reductant consumption by 15-30% through precise metering

Flexible adaptation to various industrial scenarios: The treatment air volume range is wide (5,000-500,000Nm³/h), suitable for enterprises of different sizes; special versions such as high sulfur type and high dust type can be customized to adapt to complex working conditions

Intelligent monitoring and remote management: Equipped with the Industrial Internet of Things (IIoT) platform to achieve remote monitoring and fault diagnosis; big data analysis function can predict catalyst life and maintenance cycle

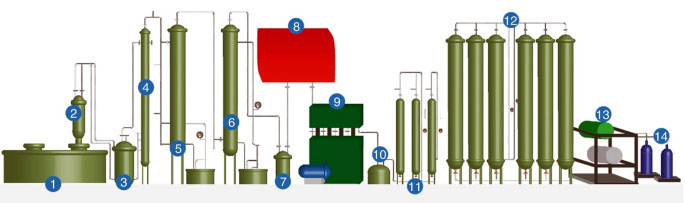

What is the process flow of Nitrogen oxide treatment equipment?

Nitrogen oxide treatment equipment parameters

| Parameter category | Index value | Test standard |

| Treatment efficiency | ≥95% (NOx removal rate) | ISO 10849 |

| Outlet concentration | ≤50mg/m³ (customizable to 30mg/m³) | GB 13223 |

| Ammonia escape | ≤3ppm | EPA CTM-027 |

| Operating temperature | 180-400°C (optimal 280-350°C) | - |

| System resistance | ≤800Pa (full load) | ISO 5801 |

| Noise level | ≤75dB(A) @1m distance | ISO 3744 |

What are the applications of Nitrogen oxide treatment equipment?

Our nitrogen oxide treatment equipment has been successfully applied to many high-pollution industries with its excellent performance and flexible configuration, helping customers achieve environmental protection standards and sustainable development goals. The following are the main application areas and typical cases of the equipment:

Power industry - Ultra-low emission transformation of coal-fired power plants

Project challenge: A 2×600MW coal-fired unit needs to reduce NOx emissions from 200mg/m³ to below 50mg/m³

Solution: Install a two-stage SCR system and use a high-temperature + medium-temperature catalyst combination

Implementation effect: NOx emissions are stable at 35mg/m³, ammonia slip <2ppm, and annual NOx emissions are reduced by about 12,000 tons

Customer benefits: Obtain local environmental protection subsidies and avoid about 8 million yuan in annual sewage fees4

Cement industry - New dry kiln tail gas treatment

Project challenge: 5000t/d cement production line kiln tail gas has high dust content (30g/m³) and large SO2 fluctuations

Solution: Customized high-dust SCR system, pre-efficient dust removal, and catalyst adopts anti-blocking design

Implementation effect: NOx is reduced from 800mg/m³ to 45mg/m³, and the system has been running continuously for 2 years without blockage

Customer benefits: meet special emission limit requirements, clinker quality is not affected9

Chemical industry - tail gas purification of nitric acid plant

Project challenge: The tail gas of nitric acid production by double pressure method contains about 2000ppm NOx and acid mist

Solution: integrated wet scrubbing + SCR system, using acid-resistant catalyst

Implementation effect: NOx emission <100ppm, by-product dilute nitric acid can be reused

Customer benefits: achieve resource recycling, annual nitric acid recovery value exceeds 2 million yuan3

Iron and steel industry - comprehensive treatment of sintering machine flue gas

Project challenge: 400m² sintering machine has large flue gas volume (1,800,000Nm³/h) and low temperature (130-180°C)

Solution: flue gas heating + low temperature SCR system, combined with activated carbon desulfurization and denitrification integration

Implementation effect: NOx<50mg/m³, SO2<35mg/m³, dioxin meets the standard

Customer benefits: Become an industry benchmark project and obtain Class A enterprise certification4

Glass industry - float glass melting furnace exhaust gas treatment

Project challenge: The temperature of the melting furnace exhaust gas is as high as 450°C and contains alkali metal vapor

Solution: High temperature SCR system, special formula anti-alkali catalyst

Implementation effect: NOx is reduced from 2500mg/m³ to below 100mg/m³

Customer benefits: Extend the catalyst life to 5 years, which is much higher than the industry average of 3 years7

Waste incineration - Municipal domestic waste treatment

Project challenge: The flue gas composition of 3×750t/d waste incinerator is complex and contains dioxins

Solution: SNCR+SCR combination process, combined with catalyst filter bags

Implementation effect: NOx<80mg/m³, dioxins<0.1ng TEQ/m³

Customer benefits: Enjoy renewable energy electricity price subsidies, annual revenue increase of about 15 million yuan9

Shipbuilding industry - Marine diesel engine exhaust gas treatment

Project challenge: Meet IMO Tier III standard (NOx<3.4g/kWh)

Solution: Compact SCR system to adapt to ship vibration and space limitations

Implementation effect: NOx emission reduction of more than 90%, certified by classification society

Customer benefits: Obtain international route operation qualifications and enhance market competitiveness4

Special application - N2O emission reduction in sewage treatment plants

Project background: N2O emissions in MABR process are increasingly receiving attention

Solution: Bio-catalytic combined treatment system to convert N2O into N2

Implementation effect: N2O emissions are reduced by 85%, and carbon footprint is reduced

Industry significance: Help the sewage treatment industry achieve carbon neutrality goals78

Our equipment has also been successfully applied to the following fields:

Petrochemical: catalytic cracking unit, hydrogen production unit

Non-ferrous metals: aluminum electrolysis, lead and zinc smelting

Ceramic industry: roller kiln, tunnel kiln

Papermaking industry: alkali recovery boiler

Food industry: boiler flue gas treatment

According to the characteristics of different industries, we provide full-process services:

Preliminary consultation: waste gas detection, scheme design, feasibility analysis

Engineering implementation: equipment supply, installation and commissioning, operation training

Operation support: remote monitoring, regular maintenance, catalyst replacement

Environmental compliance: emission testing, report preparation, license application