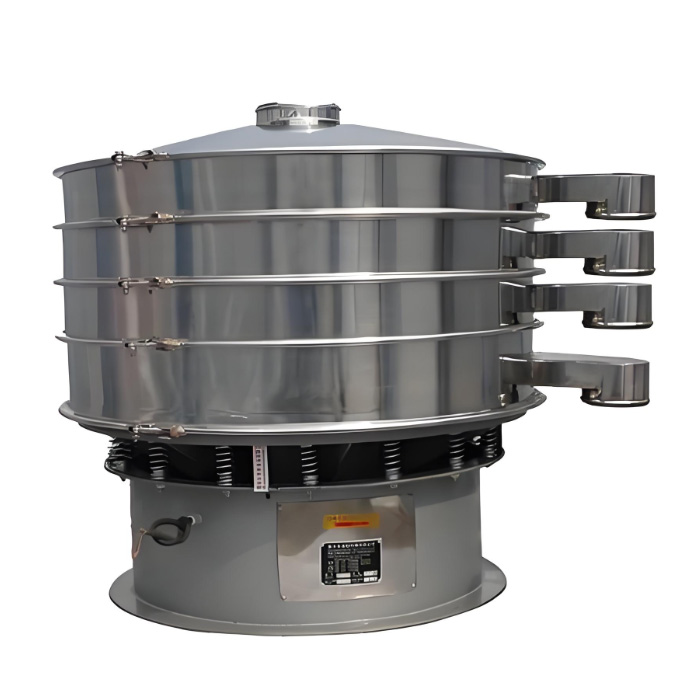

Gravel Separator Machine

It can remove impurities and classify coarse sand to fine sand of 0.074-100mm, with an output of 30 tons/hour and a screening efficiency of up to 96%

Feeding particle size: 0.074-100mm

Capacity: 0.12-30 t/h

Motor Power: 2*(0.4-3.7)kw

What is Gravel Separator Machine?

Gravel Separator Machine is used to screen and remove sand and gravel with a particle size of 0.074-100mm. It is driven by dual motors and can automatically discharge materials. It has a large output and low energy consumption. It can be used to process the full-size screening from coarse sand to fine sand.

Gravel Separator Machine has 1-5 layers and can separate sand and gravel into 2-6 different particle sizes. The models are 520, 525, 1020, 1025, 1030, etc., and the model can be selected according to the output.

What types of sand and gravel can be separated by Gravel Separator Machine?

The Gravel Separator Machine allows a maximum feed particle size of 300mm and can accurately separate various types of sand and gravel materials within the range of 2-100mm, including:

Coarse aggregate screening: 5-40mm (for concrete batching, roadbed materials)

Medium sand screening: 0.3-5mm (standard for construction sand)

Fine sand recovery: 0.15-0.3mm (high-quality mortar raw materials)

Ultra-fine sand dehydration: 0.074-0.15mm (precision casting sand)

| Sand and gravel type | Particle size range (mm) | Recommended model | Number of screen layers | Processing capacity (t/h) | Typical industry applications |

| Coarse aggregate | 5-100 | 1530 | 1-2 | 150-200 | Roadbed materials, concrete coarse aggregate |

| Medium sand | 0.3-5 | 2460 | 2-3 | 100-150 | Construction sand, asphalt mixture |

| Fine sand | 0.15-0.3 | 1020 | 3-4 | 50-80 | High-quality mortar, ready-mixed concrete |

| Ultrafine sand | 0.045-0.15 | High-frequency type | 4-5 | 15-30 | Precision casting, glass raw materials |

What are the advantages of Gravel Separator Machine?

Gravel Separator Machine has significant advantages such as efficient screening, large processing capacity, multi-level sorting, energy saving and environmental protection: the equipment adopts optimized screen surface design and motion trajectory, which can efficiently process sand and gravel materials below 400 mesh, with a screening efficiency of more than 96%, and a single unit processing capacity increased by 1-2 times compared with traditional equipment; equipped with 1-6 layers of screens, it can simultaneously sort out 2-7 materials of different particle sizes to meet diverse needs; dual motor drive provides strong excitation force, with an output of up to 30 tons/hour, while reducing energy consumption by 30%; the fully sealed structure effectively suppresses dust spillage, and the working noise is less than 80 decibels. In addition, its screen surface inclination, vibration trajectory and amplitude can be flexibly adjusted, and it can easily cope with both coarse aggregate and fine sand, showing excellent process adaptability and stability.

How does Gravel Separator Machine work?

The working principle of Gravel Separator Machine is to vibrate the sand and gravel in the screen box using the rotational motion of the motor. When the motor speed reaches a certain frequency, the screen box will generate a vertical vibration, causing the sand and gravel to fall freely on the screen. Smaller sand and gravel will pass through the pores of the screen, while larger sand and gravel will be retained on the screen. By adjusting the amplitude and frequency of the vibrator, screening effects of different particle sizes can be achieved.

Gravel Separator Machine Parameters

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

How to select a Gravel Separator Machine?

The following factors need to be considered when selecting a suitable Gravel Separator Machine:

Gravel particle size range:

Coarse aggregate (10-100mm): Use a heavy linear screen, such as the 1530 model.

Medium and fine aggregate (1-50mm): Use a medium-sized grading screen, such as the 1020 model.

Fine sand (0.074-5mm): Use a fine dewatering screen, such as the 1030 model.

Processing capacity requirements:

Small sand and gravel plant (below 10t/h): 520 or 815 model.

Medium-sized production line (10-20t/h): 1020 or 1025. Large-scale sand and gravel system (above 20t/h): 1530 or 1530

Gravel Sifting Machine

Gravel Sifting Machine Sieve For Polystyrene Pellets

Sieve For Polystyrene Pellets Foam Screening Machine

Foam Screening Machine