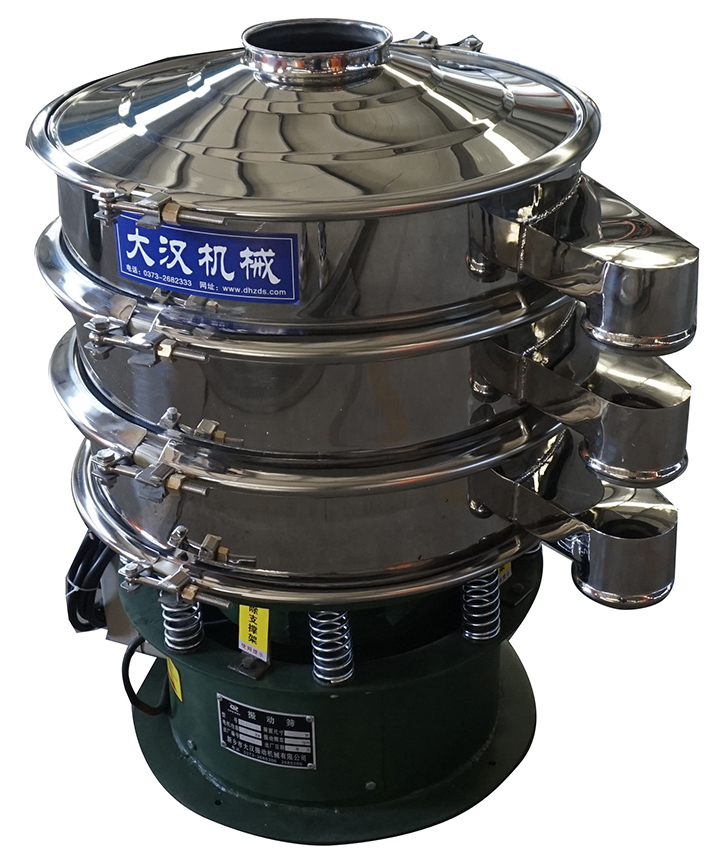

Test Sieve Machine

The price of Test Sieve Machine varies depending on factors such as model, sieve diameter, number of layers and type, and usually ranges from$300to $4320/Set

Screening particle size range:5μm-125mm

Screen diameter specifications:Φ75mm, Φ100mm, Φ200mm, Φ300mm

Single processing capacity:5-500g

Number of screen layers:1-8 layers of independent screen frames

Vibration performance parameters:amplitude ≤5mm

Material standard:SUS304 stainless steel

Operation parameters:voltage 220V (customizable), power 0.125Kw, operation noise ≤50dB

What is Test Sieve Machine?

Test Sieve Machine is an experimental device that achieves precise classification of powders, particles and suspensions through a combination of vibration and multi-layer sieves. Its core function is to drive the sieve group through a vibration source, so that the material is layered according to the particle size, thereby quickly separating samples of different particle sizes. The device is widely used in scientific research laboratories, quality inspection agencies and industrial production lines, supporting a full range of analysis from coarse particles to ultrafine powders (5μm to 125mm).

The device has a compact structure and flexible operation. The sieve diameter and number of layers are available in a variety of specifications. It can be equipped with 1-8 layers of sieves, and the single batch processing capacity is 5-500g, which is suitable for the detection needs of trace samples to medium batch samples. The body is made of SUS304 stainless steel, and its corrosion resistance meets the ASTM A240 standard. The whole machine weighs only 15-35kg, which saves laboratory space while meeting the needs of frequent movement.

How many categories are there of Test Sieve Machine?

Laboratory sieve shakers are mainly divided into four categories: Standard Laboratory Sieve Shakers, Ultrasonic Sieve Shakers, Rotap Sieve Shaker, and Electric Sieve Shaker.

Standard Laboratory Sieve Shakers: Uses electromagnetic or mechanical vibration sources, adapts to sieves with diameters of 75mm to 400mm, and is compatible with wire mesh, perforated plates, and electroformed sieves. Commonly used for laboratory particle classification, particle size detection, and teaching demonstrations.

Ultrasonic Sieve Shakers: Integrated ultrasonic transducers, designed for high-static, easily agglomerated fine powders (minimum screening to 20 microns). Commonly used for precision screening of pharmaceutical powders, pigments, and specialty chemicals.

Rotap Sieve Shaker: Through the combination of slapping and reciprocating vibration, high-intensity, high-frequency screening is achieved, and durability is excellent. Suitable for industrial-grade high-load screening tasks such as diamond micropowders and superhard materials.

Electric Sieve Shakers: The electromagnetic drive system has a vibration frequency of up to 3000 times/minute, and the dry screening efficiency can reach 20 microns (635 mesh). It is often used for rapid batch testing of food additives and cosmetic raw materials.

What are the advantages of Test Sieve Machine?

The test sieve machine has high screening accuracy, and the mesh aperture strictly complies with international standards to ensure accurate test data; it has strong adaptability and can handle a variety of materials such as powders, particles, suspensions, etc., to meet the screening needs of different particle sizes from 5μm to 125mm; the sieve frame is made of high-quality 304 stainless steel, which is corrosion-resistant, high-temperature-resistant and not easy to rust, ensuring long-term stable operation; in addition, the equipment is equipped with a timer, and the screening time can be set as needed to ensure the consistency of the test results and reduce human errors.

Technical Parameters of Test Sieve Machine

| Model | DH-75 | DH-100 | DH-200 | DH-300 |

| Nominal diameter (mm) | Φ75 | Φ100 | Φ200 | Φ300 |

| Screening size (mm) | 0.038-3 | |||

| Noise (dB) | ≤50 | |||

| Feeding amount (one-time) (g) | ≤200 | |||

| Amplitude (mm) | ≤5 | |||

| Voltage (V) | 220V(Or as required) | |||

| Power (Kw) | 0.125 | |||

| Dimensions (mm) | 360*300*736 | |||

What is the working principle of Test Sieve Machine?

The test sieve machine uses a vertical vibration motor as the vibration source, and the vibration generated by the motor is transmitted to the sieve frame through the vibration plate. When the material is placed on the top screen, under the action of vibration, particles smaller than the size of the screen hole pass through the screen and fall into the lower screen frame, while larger particles remain on the current screen. Through the multi-layer screens with gradually decreasing mesh numbers, the material is separated into different particle segments, thereby realizing the determination of particle size composition.

What are the applications of Test Sieve Machine?

Test sieve machines are widely used in pharmaceutical, food, chemical, building materials, metallurgy, geology and other fields. In the pharmaceutical industry, it is used for particle size analysis of medicinal powders and particles to ensure the quality of drugs; in the food industry, it is suitable for screening flour, sugar and food additives; in the chemical industry, it is used for the detection of chemical powders and plastic particles; in the construction industry, it is used for the analysis of sandstone and cement particles. Provide important technical support for product quality control, process optimization and scientific research.

Test Sieve Machine is a laboratory equipment that accurately classifies powders, particles and suspensions through vibration and multi-layer screens. It is widely used in scientific research, quality inspection and industrial fields. The core principle is to use a vibration source to drive the screen group, so that the material is layered according to the particle size to achieve multi-stage separation. The equipment is divided into four categories: standard vibrating screen, ultrasonic screen, rotary screen and electric screen, which are adapted to different precision and scene requirements. Advantages include high precision (screen aperture 5μm-125mm), corrosion-resistant 304 stainless steel body, flexible multi-layer screening (1-8 layers) and automatic timing function to ensure detection efficiency and data consistency. It is widely used in the pharmaceutical, food, chemical and other industries for raw material testing, process optimization and quality control, and is an important tool in the field of particle analysis.