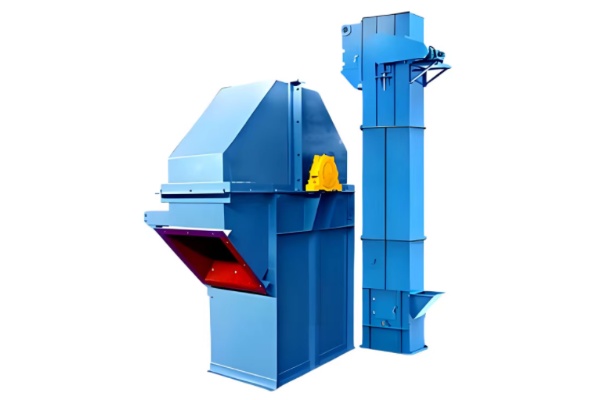

Plastic Particles Bucket Elevator

The price of plastic particles bucket elevator ranges from $199 to $4,800 , depending on the model, material and customization requirements.

Material: stainless steel

Lifting speed: 1.8-2 m/s

Conveying capacity: 200 t/h

Power: 15KW

Voltage: 240v/380v/415v/450v

Capacity of bucket elevator: 5 t/h-300 t/h

What is Plastic Particles Bucket Elevator?

Plastic Particles Bucket Elevator is a mechanical device specially used for vertical conveying of plastic particles. Its core function is to stably lift plastic particles at a lower position to a higher position to meet the material feeding height requirements of the production process. In view of the characteristics of plastic particles, the equipment design takes into account its fluidity, cleanliness requirements and possible dust. The conveying capacity of Plastic Particles Bucket Elevator is wide. Common types include conveyor belt bucket elevators, whose processing capacity can range from several tons to tens of tons per hour, and can also be configured according to specific production needs.

What are the types of Plastic Particles Bucket Elevator?

In view of the characteristics of plastic particles, Plastic Particles Bucket Elevator usually tends to choose centrifugal unloading bucket elevators, and conveyor belts are more common than chains in traction components.

Centrifugal unloading bucket elevatorsFeatures of centrifugal unloading bucket elevators: The bucket runs at a higher speed and throws the material out at the top by centrifugal force. The bucket spacing is large, and the bottom is usually circular or arc-shaped.

Applicable materials: Suitable for conveying materials with good fluidity, small particles, no or weak abrasiveness, and not easy to break. Plastic particles usually belong to this type of material, so centrifugal unloading is very common in plastic particle elevators.

Advantages: simple structure, relatively low cost, large processing capacity, and fast running speed.

Disadvantages: There is a certain impact on the material, and it is not suitable for conveying fragile or sticky materials.

Features of conveyor belt bucket elevator: The bucket is fixed on the rubber belt or wire rope core belt. The belt runs smoothly and has low noise.

Applicable materials: Suitable for conveying materials with light specific gravity, good fluidity, low temperature, or low requirements for material breakage rate. Plastic particles usually tend to choose belt type.

Advantages: Smooth operation, low noise, suitable for high-speed operation, small impact on materials, and easy maintenance.

Disadvantages: Not resistant to high temperatures, not suitable for conveying large or sharp materials, and the carrying capacity is relatively weak compared to chains.

Basic parameters of Plastic Particles Bucket Elevator

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

What are the advantages of Plastic Particles Bucket Elevator?

As a vertical conveying equipment, Plastic Particles Bucket Elevator has many advantages in the plastic processing, modification, recycling and other industries, making it an ideal choice for conveying plastic particles.

Vertical conveying, saving floor space: The biggest advantage of bucket elevators is their vertical conveying capacity. Compared with horizontal conveying equipment (such as belt conveyors and screw conveyors), it can directly lift materials from low to high, greatly saving ground space. This is of great practical significance for factories with limited production workshop area or the need to achieve multi-layer three-dimensional layout.

Enclosed conveying, control of dust and pollution: Plastic particles may generate a small amount of dust during the conveying process, especially when running at high speed or friction. The bucket elevator adopts a fully enclosed casing structure, which can effectively prevent dust from overflowing and improve the working environment. At the same time, the enclosed design also prevents external impurities from entering the material and ensures the cleanliness of plastic particles, which is particularly important for the plastic processing industry that has strict requirements on product purity.

Strong adaptability to material characteristics (especially for particles with good fluidity): Plastic particles generally have good fluidity. Bucket elevators (especially the common centrifugal discharge design) can make full use of this characteristic of particles and smoothly throw out the particles through the high-speed operation of the hopper to achieve discharge. This method reduces the residual material in the hopper and improves the conveying efficiency.

What are the applications of Plastic Particles Bucket Elevator?

Plastic Particles Bucket Elevator is mainly used in production and storage links where plastic particles need to be transported from a lower position to a higher position. This type of equipment undertakes the task of vertical material transfer in various scenarios involving particle material processing.

Raw material feeding and transportation to processing equipment: In the process of plastic product manufacturing, plastic particle raw materials purchased in large quantities are usually stored in storage silos or hoppers on the ground floor. Bucket elevators can lift these raw materials from the bottom of the storage silo to the feed port or hopper of the extruder, injection molding machine or other molding equipment. This ensures that the processing equipment can continuously obtain material supply and maintain the continuous operation of the production line.

Material transfer in the intermediate process link: In some complex plastic processing processes, materials may need to go through multiple processing stages, such as crushing, cleaning, drying, mixing, modification or granulation. Between these different process units, when materials need to be transferred vertically, bucket elevators are used to transport plastic particles that have completed one stage of processing to the feed port of the next processing equipment. For example, the granulated particles are lifted to the cooling or screening equipment.

Conveying and packaging of finished particles: When plastic particles need to be stored or packaged as final products, bucket elevators can lift the finished particles that have completed all processing steps from the discharge point of the production line to the top feed port of the packaging machine, silo or big bag filling equipment. This helps to achieve automated packaging and centralized storage, simplifying the material handling process.

Plastic Particles Bucket Elevator Manufacturer

The equipment produced by the Plastic Particles Bucket Elevator manufacturer not only has the common advantages of small footprint and closed transportation to reduce losses, but also provides gentle protection for materials and minimizes particle breakage. The plastic bucket it uses has the characteristics of corrosion resistance, lightweight, and spark-free, which significantly improves the safety and service life of the equipment when conveying plastic particles. In addition, according to different production needs, bucket elevators are designed in a variety of types. For example, centrifugal elevators are suitable for high-speed and large-volume particle transportation; while gravity elevators are known for their low damage to fragile materials. In terms of traction components, belt types are popular because of their smooth operation and low noise, while chain types are suitable for occasions that require higher load-bearing capacity. Our manufacturer can not only provide standardized products, but also has customized production capabilities. Whether it is a special size of inlet and outlet, or a hopper design to cope with the specific physical properties of the particles, we can tailor it according to the detailed requirements of our customers, such as specific lifting height, conveying capacity, plant space restrictions, physical properties of plastic particles (such as density, flowability, fragility), and whether explosion-proof or clean environment is required.

In the current plastic processing and related production, Plastic Particles Bucket Elevator is mainly responsible for lifting granular materials from low to a specified height. Its fully enclosed design helps manage dust in the working environment and prevents external substances from affecting the material. The equipment structure adapts to the characteristics of plastic particles and ensures that the physical state of the material is relatively stable during the lifting process. In different links of the production line, this elevator provides a way to accurately transport materials to subsequent equipment, supporting the continuity of the production process. The operation and maintenance of the equipment depends on its fixed mechanical parts and established operating procedures to ensure that it can perform its conveying functions in actual operations.