Horizontal plowshare mixer

Horizontal plowshare mixer is a highly efficient and versatile powder mixing equipment, widely used in chemical, food, pharmaceutical, building materials and other industries. Its core design achieves rapid and uniform mixing of materials through a unique mechanical structure, and is particularly suitable for the mixing process of viscous, paste or high-density materials.

What is a horizontal plowshare mixer?

Horizontal plowshare mixer is a highly efficient and versatile powder mixing equipment, belonging to a high-efficiency intermittent mixer, named because its core stirring component is shaped like a plowshare. This equipment is widely used in chemical, building materials, pharmaceutical, food, feed and other industries, and is suitable for the mixing process of adding a variety of powders, particles and a small amount of liquid (mixing of powders with powders, powders with liquids, powders with particles), especially suitable for processing viscous, agglomerated materials or processes that require crushing and dispersion. With its unique structure and working principle, this equipment can achieve rapid and uniform mixing, and is particularly suitable for processes that add a small amount of liquid or require shear mixing.

Applicable materials

Powdered, granular, and fibrous materials;

Liquids with a small proportion (such as pigments and oils);

Materials with slight agglomeration or need to be broken.

What is the difference between a vertical mixer and a horizontal mixer? Make a table and give specific values

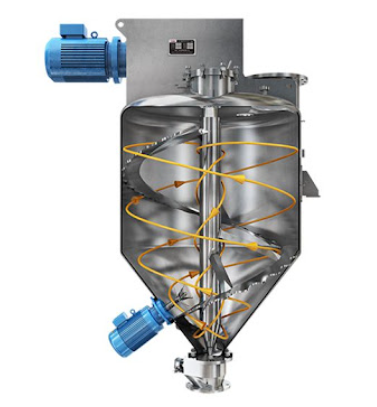

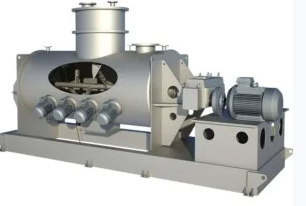

| Comparison items | Vertical mixer | Horizontal mixer |

| Image |

|

|

| Structural form | Vertical cylinder, spiral or scraper circulates and mixes materials from bottom to top | Horizontal cylinder, using spiral ribbon, plowshare, paddle and other stirring structures |

| Mixing time | Relatively long: 10~20 minutes/batch | Relatively short: 3~10 minutes/batch |

| Mixing uniformity (CV) | Generally ≤7% | Can reach ≤5%, some can be as low as ≤3% |

| Applicable materials | Suitable for granular and fluid powder | Powder, granules, fibers and liquid-added materials, more adaptable |

| Loading factor | About 60%~70% | About 40%~60% |

| Floor area | small floor space (high structure) | large floor space (low structure) |

| Residue | small, discharge by gravity, the bottom structure of the barrel is conducive to the clean discharge of materials | relatively large, need to pass through the discharge valve, some materials remain at the bottom of the barrel |

| Typical uses | feed mixing, plastic granule mixing, fertilizer premixing | dry powder mortar, food additives, chemical powder, high-precision mixing |

| Suitable for continuous production? | Not very suitable, mainly intermittent mixing | can achieve continuous or intermittent mixing |

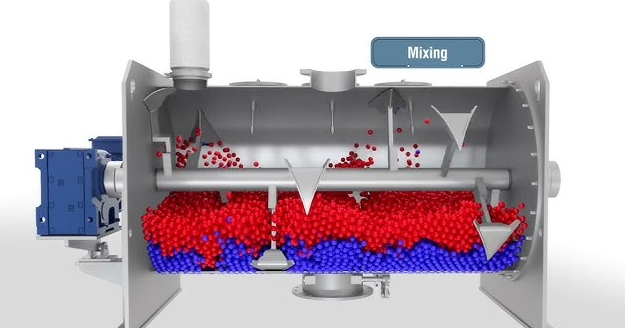

Working principle of horizontal plowshare mixer

The plowshare mixer drives the plowshare blade to rotate at high speed through the main shaft, throws the material up, forms a fluidized motion, and quickly breaks up and mixes the material in the barrel. At the same time, the flying knife (if any) performs strong shearing and breaking action to enhance the interaction between materials and improve the mixing efficiency. The entire mixing process is intermittent, and the degree of mixing can be controlled by time.

Radial motion: When the plowshare rotates, the material is thrown around along the barrel wall.

Axial movement: Specially arranged plowshares push the material to flow along the axial direction of the cylinder.

Convection mixing: Materials flowing in different directions intersect with each other to form convection and achieve uniform mixing.

Shearing and dispersion: Some horizontal plowshare mixers are also equipped with high-speed flying knives to break up agglomerated materials and further improve mixing efficiency and uniformity.

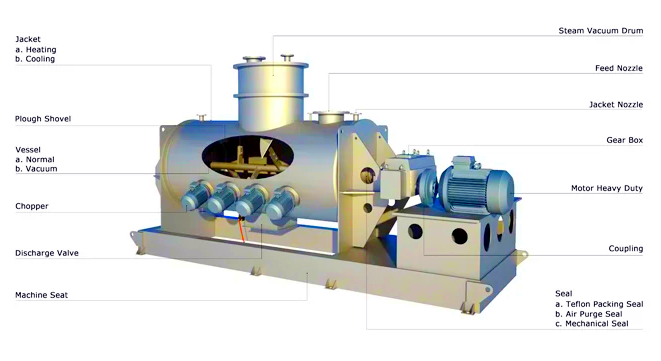

Structural composition

Horizontal U-shaped cylinder: A horizontally placed mixing container with a smooth inner wall or a wear-resistant lining to reduce material residue.

Plow blade stirring device:

Main plowshares: Arranged along the axial direction of the cylinder, when rotating at high speed, the material is thrown from the bottom to the space to form a three-dimensional flow.

Flying knife group: Installed on the side wall of the cylinder, shearing and crushing agglomerated materials at high speed to enhance the dispersion effect.

Drive system: Usually driven by motor + reducer, the speed can be adjusted to adapt to different material characteristics.

Auxiliary devices: Optional heating/cooling jackets, vacuum systems, liquid spraying devices, etc. to meet special process requirements.

What are the advantages of horizontal plowshare mixers?

High mixing efficiency: The general mixing time is between 2 and 10 minutes, and materials with large differences in particle size and density can be mixed. The combined action of the plowshare and the flying knife enables the material to be turbulent, scattered and replaced quickly, and can achieve uniform mixing in a short time.

High mixing accuracy: It can achieve high-precision mixing of materials with large differences in particle size and density, ensuring good quality uniformity of the mixed materials, and it has the best fiber separation performance.

Strong adaptability: It is particularly suitable for occasions with high fiber content and large spray volume. It also has a good effect on the mixing of viscous or colloidal additives, and can also crush and mix agglomerated materials.

Good sealing: The horizontal closed cylinder structure makes it easy to connect the inlet and outlet with the dust removal equipment, reduce dust leakage, and have little impact on the environment of the mixing area. At the same time, it can also prevent external impurities from entering the mixer.

Common specifications

| Model | Effective volume (L) | Motor power (kW) | Equipment weight (kg) | Processing capacity (kg/batch) |

| LDH-100 | 100 | 3 | 400 | 30~60 |

| LDH-500 | 500 | 7.5 | 1200 | 150~300 |

| LDH-1000 | 1000 | 11 | 1800 | 300~600 |

| LDH-2000 | 2000 | 18.5 | 2800 | 600~1200 |

| LDH-3000 | 3000 | 22 | 3500 | 900~1800 |

What is a horizontal plowshare mixer used for?

Horizontal plowshare mixers are widely used in building materials, chemicals, pharmaceuticals, agro-pharmaceuticals, food, feed and feed additives, coatings, plastics and other industries, such as solid-solid (powder to powder), solid-liquid mixing (adding a small amount of powder to a liquid), as well as wet granulation, drying and compounding processes. It is especially suitable for mixing viscous or rubbery additives. The equipment can also be specially designed for processing powders, granular products, grains, brittle materials, semi-viscous products and cement concrete materials.

Plowshare mixing process, dry powder mixing

Paste mixing, wet slurry mixing

Wet granulation, liquid coating of powders and granules

Grease incorporation, vacuum drying

What factors should be considered when selecting a powder mixing and mixing system?

Continuous mixing or intermittent mixing method: Batch processing allows traceability.

Batch size: It is important to find the right balance, as too large a batch may result in uneven mixing.

Mixing time: Shortening the mixing time reduces processing costs and reduces degradation of sensitive materials. However, a balance must be struck between mixing uniformity and cycle time.

Power consumption: Energy efficiency is critical. S&L has extensive experience in designing energy-efficient mixing and stirring systems.

Easy unloading: Unloading capability is one of the key functions of batch mixers. It is essential to ensure that the mixed material is completely unloaded without leaving any residue.

Easy to clean: Proper cleaning is essential for equipment used to mix and stir different materials.

Supplier of horizontal plowshare mixers

Xinxiang Dahan Vibration Machinery Co., Ltd. is a professional manufacturer of vibrating screen equipment and mixing equipment located in Xinxiang, Henan, China, focusing on the design, production and sales of screening, conveying, mixing and other equipment.

Equipment types include horizontal plowshare mixers, which use horizontal cylinders, equipped with plowshares and flying knife groups, suitable for powders, granules, solid-liquid mixing. Material options include carbon steel or 304/316L stainless steel, and anti-corrosion or wear-resistant coatings can be added to the material contact parts. Widely used in chemical (dry mortar, coatings), food (feed additives), medicine (pharmaceutical raw materials), building materials, etc. Dahan Machinery emphasizes non-standard design and can be customized according to customer needs.

Contact Dahan Machinery:

My whatsapp: +86 15236742901, e-mail: sale@xxdahan.com