Various vacuum feeder

Facing the diverse demands of different industries for the transportation of powder and granular materials, vacuum feeders have derived various types to adapt to complex working conditions with their technological iteration and functional innovation.

Power: 1.5-5.5 kW (customizable)

Size (length * width * height): Depends on the specific model (customizable)

Material: stainless steel / carbon steel

Voltage: 220V / 380V / 415V or according to the order

Type: pneumatic / electric / fully automatic / explosion-proof

Scope of application: Conveying materials such as flour, wheat flour, sugar, milk powder, seasoning, coffee beans, etc.

Various vacuum feeder

Various vacuum feeder are the core equipment of modern powder conveying. They realize efficient and dust-free material transmission through negative pressure airflow technology, which can meet the diversified needs of pharmaceutical, food, chemical and other industries. We provide a full range of models, including electric, electric, explosion-proof, food-grade and customized solutions, covering the full range of applications from laboratory research and development to industrial production. The equipment adopts modular design and supports intelligent control and automation integration.

What are the different types of vacuum feeders?

Vacuum feeders can be divided into various types according to driving mode, operation mode and structural characteristics to meet the diversified needs of different industries and production scenarios.

Classification by driving mode

Electric vacuum feeder: Use electric vacuum pump as vacuum source, drive vacuum pump through motor to generate negative pressure inside the system. It has strong vacuum suction and is suitable for occasions with long conveying distance and large conveying volume. Its conveying capacity can reach 10t/h, and its small size can flexibly adapt to different production layouts.

Pneumatic vacuum feeder: Use compressed air to drive vacuum generator to generate vacuum. The compressed air driven mode makes the equipment generate no heat when running, which has the advantages of explosion-proof and no hidden dangers. It is particularly suitable for industries with high safety requirements, such as chemical industry and pharmaceutical industry.

Classification by operation mode

Manual vacuum conveying feeder: The suction nozzle needs to be manually operated by humans and placed at the material. After starting the vacuum system, the material is sucked into the conveying pipeline and transported to the target location. It has a simple structure and low cost, but the labor intensity is high. It is suitable for small-scale material transportation and processing.

Semi-automatic vacuum conveying feeder: The material conveying process is carried out through an automatic control system, such as automatic control of vacuum generation, material suction and transportation, etc. Compared with the manual type, its degree of automation is improved, which can reduce the labor intensity of manual labor to a certain extent. It is suitable for production scenarios that have certain requirements for automation but do not require full automation.

Fully automatic vacuum conveying feeder: The entire material conveying process is fully automated, including the automatic suction, transportation, unloading of materials in the target equipment, and cleaning and maintenance of the equipment, which can be automatically completed through preset programs. It is suitable for large-scale and continuous production enterprises.

Features of vacuum feeder

It covers a variety of series, adopts negative pressure airflow technology to achieve pollution-free transmission of powder/particles, and supports customized control and automation integration.

Fully enclosed conveying system: adopts negative pressure working principle to achieve closed conveying of materials throughout the process, and completely eliminates dust leakage.

Medical grade cleanliness standard: The inner surface of the equipment is Ra≤0.4μm mirror polished, with no sanitary dead corners, and meets GMP/FDA certification requirements.

Multiple filtration design: equipped with primary efficiency + high efficiency (0.3μm) two-stage filtration, and optional HEPA ultra-high efficiency filtration system.

Fast conveying capacity: The maximum conveying capacity can reach 20 tons/hour, and the maximum conveying distance is 50 meters.

Special material solution: High-viscosity materials are equipped with pipeline vibrators + airflow auxiliary devices, fragile materials adopt low-speed and gentle conveying mode, and easily oxidized materials can choose nitrogen protection system.

Material diversity: 304/316L stainless steel, carbon steel, PP/PVDF and other materials can be selected.

Functional modularization: 30+ functional modules such as explosion-proof, weighing, sterilization, etc. are optional.

Layout adaptability: supports complex pipeline layouts such as horizontal, vertical, and multi-angle.

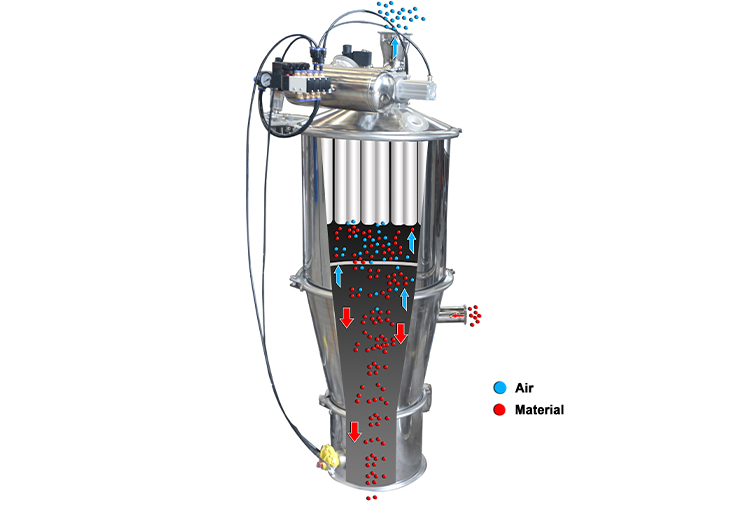

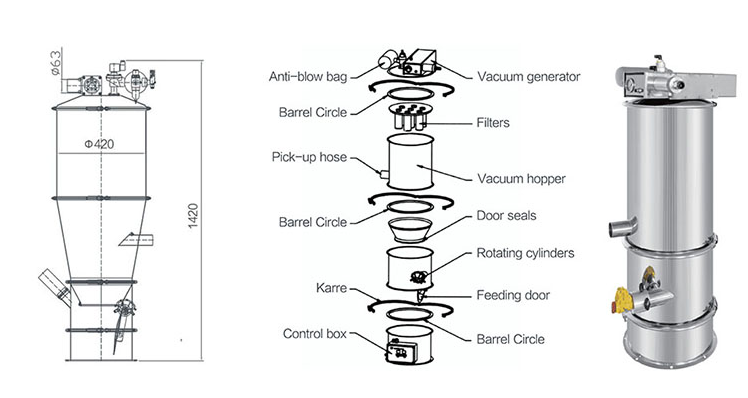

Working principle of vacuum feeder

The electric vacuum feeder generates negative pressure through an electric vacuum pump, so that a pressure difference is formed at the suction nozzle, and the powder and granular materials are sucked into the conveying pipeline with the airflow; after the material reaches the hopper, it is separated from the gas and solid by a high-efficiency filter, and the clean air is discharged from the system; when the material level reaches the set value, the pneumatic reversing valve opens, and the material falls into the receiving equipment under the action of gravity. At the same time, the compressed air pulse backwash cleans the filter element to ensure continuous and stable operation.

Model parameters

|

Model |

Motor Power (KW) |

Conveying Capacity (Koh) |

|

HCSL - 1 |

1.5 |

400 |

|

HCSL - 2 |

2.2 |

600 |

|

HCSL - 3 |

3 |

1200 |

|

HCSL - 4 |

5.5 |

2500 |

|

HCSL - 6 |

5.5 |

3200 |

|

HCSL - 7 |

7.5 |

6000 |

|

HCSL - 10-6 |

7.5 |

6000 (When the conveying distance is 10 meters) |

|

HCSL - 20-5 |

11 |

5000 (When the conveying distance is 20 meters) |

In which industries can the vacuum feeder be used?

Vacuum feeder is widely used in pharmaceutical, food (, chemical and other fields with its dust-free, high-efficiency and automated characteristics, supporting explosion-proof, food-grade and customized requirements, and improving production efficiency and cleanliness standards.

Food processing industry: widely used in the transportation of flour, wheat flour, sugar, milk powder, seasoning, coffee beans and other materials. Flour can be quickly and accurately transported to the mixer, ensuring the efficiency and hygiene of the bread making process.

Pharmaceutical manufacturing industry: can realize the automation of the drug production process and comply with GMP It is an important equipment for standardization. It can be used to convey various pharmaceutical raw materials such as Chinese medicine extract powder, antibiotic powder, vitamin raw material powder, etc., and accurately convey the materials to mixers, tablet presses, capsule filling machines and other equipment.

Chemical industry: In chemical production, it is often necessary to convey various powdered or granular chemical raw materials, such as aluminum oxide, aluminum hydroxide, zinc stearate, calcium carbonate, diatomaceous earth, etc. The vacuum feeder can effectively prevent the leakage and dust pollution of chemical raw materials while ensuring the efficiency of material conveying.

Plastic industry: The vacuum feeder can feed polyethylene particles, polystyrene particles, polyurethane particles and other plastics. The raw materials are quickly transported to the injection molding machine, extruder and other equipment to realize the automated production of plastic processing.

How to choose a vacuum feeder that suits you?

From the material characteristics, conveying distance, production capacity requirements and other aspects as the selection points, we can help you quickly match the appropriate vacuum feeder model to ensure high-speed, stable and low-consumption powder conveying solutions.

Material form and particle size

Powder type: Pay attention to fluidity. For materials with poor fluidity (such as ultrafine powder), it is recommended to choose a Roots blower with stronger suction and match it with an anti-blocking screen; for materials with good fluidity, a vacuum pump type can be selected to reduce energy consumption.

Particle type: particle size > 5mm, it is necessary to confirm the size of the equipment feed port (generally ≥2 times the particle diameter) to avoid blockage; a volumetric suction machine is recommended to prevent particle accumulation through pulse backflushing.

Mixed materials: Prioritize equipment with a multi-stage filtration system, such as a cyclone separator + filter element combination, to ensure the separation efficiency of materials with different particle sizes.

Physical properties of materials

Hygroscopicity: Materials that are prone to agglomeration in a humid environment (such as sugar and salt) need to be equipped with moisture-proof filter elements and hoppers with heating and drying functions.

Corrosiveness: When contacting strong acid and strong alkali materials, the inner wall of the equipment must be made of 316L stainless steel or fluoroplastic coating to prevent metal rust from contaminating the material.

Flammability and Explosion: Materials with dust explosion risks must use explosion-proof motors + anti-static filter elements, and the equipment grounding resistance must be ≤4Ω, in compliance with ATEX or UL explosion-proof certification.

Conveying volume and distance

Small batch and short distance: small vacuum pump type can be selected, which is small in size and low in noise, suitable for laboratories or small production lines.

Medium batch and medium distance: Roots blower type is recommended, with stable wind pressure, suitable for plastic granulation and chemical raw material transportation, and frequency conversion control can adjust the flow rate.

Large batch and long distance: high-pressure blower is required + Multi-stage pipeline relay, or with pneumatic conveying system, while calculating the pipeline diameter to avoid excessive pressure drop.

Various vacuum feeder manufacturers

As a professional vacuum feeder manufacturer, Dahan Machinery has been focusing on the research and development of high-quality conveying equipment that meets standards for more than ten years, providing intelligent powder conveying solutions for the pharmaceutical, food, chemical and new energy industries. With strong non-standard customization capabilities (supporting special needs such as 316L stainless steel, explosion-proof, and aseptic), independently developed intelligent control systems (±0.5% accuracy) and a complete one-stop service system, we have successfully provided reliable equipment to more than 500 companies in more than 30 countries and regions around the world, and continue to promote industry progress with technological innovation.

Vacuum feeders have become an ideal choice for material transportation in modern industrial production with their diverse types, advanced working principles, significant characteristics and wide application fields. Whether it is to improve production efficiency, ensure the cleanliness and hygiene of the production environment, or meet the special requirements of different industries for material transportation.