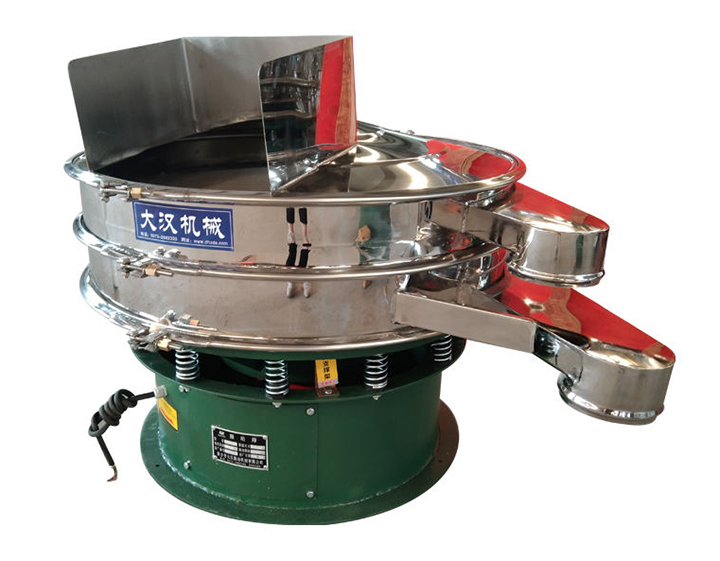

Laboratory Vibrating Sifter

The price of Laboratory Vibrating Sifter varies with different models and materials, with a range of $300to $4320/Set.

Screen diameter specifications:Φ200mm, Φ75mm, Φ100mm, Φ200mm, Φ300mm, Φ400mm

Number of screening layers:1-7 layers

Vibration frequency:290±6 times/minute

Screening range:20μm-125mm

Power parameters:Motor power 0.37KW

Timing function:0-99 minutes can be set

What is Laboratory Vibrating Sifter?

Laboratory Vibrating Sifter is a precision screening equipment designed for laboratory scenarios. It is mainly used for separation, classification and particle size detection of powders, particles and suspensions. It can quickly and efficiently measure the size of solid particles in the range of 20μm to 125mm, and can even achieve ultra-fine screening as low as 5μm through special technology. The equipment adopts a modular design and adapts to a variety of experimental needs, providing accurate particle size data support for scientific research and quality inspection.

The diameter of the equipment covers specifications such as 75mm, 100mm, 200mm, 300mm and 400mm, among which the standard sieve of 200mm to 300mm is more commonly used. It can be configured with 1-8 layers of sieve frames, which can accurately separate 2-7 particle segments at the same time, and has a 0-99 minute timing function to ensure experimental repeatability. The sieve frame material can be selected from stainless steel, nylon or all-copper to meet the screening requirements of different materials.

How many categories are there in Laboratory Vibrating Sifter?

Standard laboratory vibrating screen: divided into 300 type and 400 type, mainly adapted to screen frames of different diameters, and the matching screen mesh is usually 8 mesh to 400 mesh. It is suitable for separation and classification of powders, particles and suspensions in various laboratories. It is easy to operate and can meet the needs of conventional particle size analysis.

Ultrasonic laboratory vibrating screen: equipped with ultrasonic transducer, specially designed for fine powders with high static electricity, strong adsorption, high density and light specific gravity. It can be screened to 20μm without blocking the net, effectively solving the problem of fine powder screening and greatly improving the screening efficiency and accuracy of ultra-fine materials.

Electric vibrating screen: with electromagnetic vibrator as the vibration source, the vibration frequency reaches 3000 times/minute, which improves the screening efficiency of fine materials. Dry screening can reach 20μm (635 mesh), which is suitable for rapid screening and analysis of fine particle materials.

Slapping vibrating screen: It has dual motions of slapping and reciprocating, and can control the screening time at a fixed time. It is suitable for high-intensity, high-frequency repeated use in the production and grading process of diamond micropowder and superhard materials industry, and can cope with difficult screening tasks.

What are the advantages of Laboratory Vibrating Sifter?

The laboratory vibrating screen has high screening accuracy and can accurately measure the particle size from 20μm to 125mm, ensuring the reliability of the test data; the screen box and vibration plate are made of high-quality 304 stainless steel, which is corrosion-resistant, high-temperature-resistant, not easy to rust and non-magnetic, ensuring the long-term stable operation of the equipment; equipped with a timing relay, the working time can be set from 0 to 99 minutes, reducing the detection error and ensuring the consistency of the sample analysis data; up to 8 layers of test sieves (including the sieve bottom) can be installed, which can accurately separate a product into 2-7 particle segments at the same time, improving the experimental efficiency.

Technical Parameters of Lab Vibrating Screen

| No. | Name | Unit | Parameter |

| 1 | Sieve diameter | mm | Φ200 |

| 2 | The quantity of layer | layers | 1-7 |

| 3 | Number of revolution | times/min | 290±6 |

| 4 | Tapping | times/min | 1-4 |

| 5 | Tapping height | mm | 38±6 |

| 6 | Levelness of the base | mm/m | ≤0.6 |

| 7 | Motor power | KW | 0.37 |

| 8 | Power supply | V | 380,220 |

| 9 | Outside dimension | L*W*H (mm) | 433*432*785 |

| 10 | Rotation distance | mm | 25 |

What is the working principle of Laboratory Vibrating Sifter?

The laboratory vibrating screen relies on two reverse motors of the same frequency to drive the screen surface to produce linear vibration, so that the material moves forward in a jumping manner on the screen surface. When mixed materials of different particle sizes enter the screen surface, some particles come into contact with the screen surface. The vibration of the screen box loosens the material layer on the screen, expanding the gaps between large particles, and small particles take the opportunity to pass through the gaps and enter the lower layer. Since the gaps between small particles are small, large particles cannot pass through. The originally disordered particle group is layered according to particle size, with small particles in the lower layer and coarse particles in the upper layer, thus achieving material screening and grading.

What are the applications of Laboratory Vibrating Sifter?

Laboratory vibrating screens are widely used in various fields. For example, in the metallurgical field, they are used to screen metal powders such as tungsten powder and molybdenum powder, and control the particle size distribution to ensure the density of powder metallurgy products; in the chemical industry, they are used to classify catalyst particles and pigment powders to ensure reaction efficiency and coloring uniformity; in the pharmaceutical field, they are used to process medicinal starch and ultrafine powders of traditional Chinese medicine, and remove agglomerated impurities by screening, in compliance with GMP cleanliness standards; in the building materials industry, they are used to screen cement clinker powder and ceramic glaze particles to optimize product strength and gloss; in geological research, they are used to analyze sandstone particles and soil colloids to assist in mineral exploration and environmental monitoring; and in university laboratories, they are often used for particle size detection of nano-calcium carbonate and graphene powders to provide accurate data for the development of new materials.