Small granule quantitative packaging machine

Small granule quantitative packaging machines typically cost between$300 and $2,500 .There are many models to choose from, usually categorized by capacity (e.g. 1-50 g, 10-500 g, 100-1000 g) and speed.

Packaging capacity: 1–100 g range

Packaging speed: 20–60 bags/min

Weighing method: electronic weighing system

Error range: within ±0.2 g

Applicable materials: granules, seeds

Power supply: 220V/0.5–1.5kW

What is Small granule quantitative packaging machine?

The price of Small granule quantitative packaging machine is usually between $300 and $2500. This packaging machine is used to automatically weigh and pack granular products into bags or containers with high precision. It is particularly suitable for small and medium-sized enterprises, start-ups or workshops that handle granular items such as sugar, salt, seeds, rice, beans, spices, desiccants, tea and even small plastic granules. The machine is compact, easy to operate, and designed for quantitative (fixed weight) filling. Core parameters include weighing range, packaging speed, accuracy, power supply and sealing method.

Common models of Small Granule Quantitative Packaging Machine include: SG-50, SG-500, SG-1000 and SG-Combo. These models are mainly distinguished by packaging capacity and running speed. For example, SG-50 is suitable for materials of 1-50 grams, SG-500 is suitable for 10-500 grams, and SG-1000 is suitable for 100-1000 grams. The packaging speed of each model is roughly between 15-40 bags/minute, which can meet the diverse needs from small workshops to large enterprises.

What are the advantages of Small granule quantitative packaging machine?

Small granule quantitative packaging machine has compact size, simple operation, high-precision packaging capability, and is suitable for multi-variety granule packaging needs with limited space.

Compact size: The equipment is compact in design and is very suitable for places with limited space, such as home workshops, laboratories, small production lines, etc.

High-precision quantitative packaging: With high weighing and packaging accuracy, each bag of product meets the set weight requirements.

Easy to operate: Most devices are equipped with a user-friendly control interface, which only requires simple training to get started, reducing the threshold for employment.

Portability and functionality: Small size but powerful functions, suitable for automatic packaging of a variety of granular products, ideal for start-ups or multi-variety production scenarios.

How to choose the right Small granule quantitative packaging machine model?

When choosing a Small granule quantitative packaging machine, you should consider product type, daily output, available space and budget. Here are some common models and their price ranges:

SG-50 is a small entry-level granule packaging machine that supports 1-50g packaging and a speed of 20-30 bags/minute. It is suitable for light granules such as tea and seeds. The price is about US$300-450, which is a cost-effective choice for home workshops and small businesses.

SG-500 is suitable for packaging of 10-500 grams, with a speed of 20-40 bags/minute. It is suitable for food granules such as rice, salt, and sugar. It is easy to operate and has good stability. It is widely used in food factories and grain processing plants. The price is between 600-850 US dollars.

SG-1000 supports packaging of 100-1000 grams, with a speed of 15-35 bags/minute. It is suitable for large packaging scenarios such as beans, nuts, and chemical granules. It is suitable for medium-sized food or daily chemical companies. The price is about 900-1200 US dollars.

SG-Combo is a multi-functional model with a packaging range of 1-500 grams. It supports back sealing and a variety of bag types. It has an automatic cutting system. It is suitable for fine packaging needs such as seasonings and health granules. The price range is 1200-2500 US dollars. It is suitable for users who have high requirements for packaging aesthetics and efficiency.

Small granule quantitative packaging machine product display

What are the technical parameters of Small granule quantitative packaging machine?

Small granule quantitative packaging machine has a weighing range of 1–1000g, a speed of 10–60 bags/minute, an accuracy of ±0.2–1g, is suitable for dry granules, supports heat-sealed film packaging, has a power consumption of 200–800W, and is easy to operate. The specific parameters are as follows:

Weighing range: 1g–1000g (depending on the model)

Packaging speed: 10–60 bags/minute

Accuracy: ±0.2–1g

Voltage: 110V/220V, 50/60Hz

Power consumption: 200W–800W

Control system: mainly microcomputer or PLC

Material compatibility: dry, free-flowing granules

Packaging material: heat-sealed film (e.g. PE, OPP, aluminum foil)

Sealing type: heat-sealed, optional customization

Weight: 25kg–70kg

Machine size: varies, but generally about 400mm×500mm×700mm

What are the common applications of Small granule quantitative packaging machine?

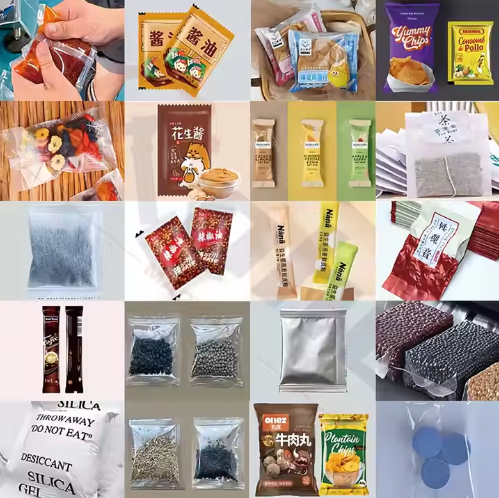

Small granule quantitative packaging machine is widely used in many industries such as food, medicine, chemical industry, agriculture, etc., especially for quantitative packaging of various dry and fluid small granular materials. For example, in the food industry, it can be used to package candies, nuts, seeds, seasonings, coffee beans, chicken essence, oatmeal, etc.; in the pharmaceutical industry, it can be used to package medicinal granules or health care granules; in the chemical field, it is used to package chemical raw materials such as plastic particles and desiccants; in agriculture, it can be used to package feed additives, granular fertilizers, etc. Due to its small footprint, simple operation and convenient maintenance, it is particularly suitable for multi-variety and small-batch production environments that require frequent changes in materials and packaging specifications.

What are the common cases of Small granule quantitative packaging machine?

In actual applications, Small granule quantitative packaging machine is often used with a variety of bag types to meet the packaging needs of different industries. Specific examples include: food factories use three-side sealed bags to package 5g seasonings and granular sugar to ensure sealing and portability; health care products companies use four-side sealed bags to package granular vitamins to ensure accurate dosage and beautiful appearance; agricultural companies choose self-supporting bags to package 10g vegetable seeds for easy display and storage; chemical companies use back-sealed bags to package desiccant granules to improve packaging efficiency and reduce material waste. The flexible application of different bag types enables the equipment to adapt to diverse market needs.

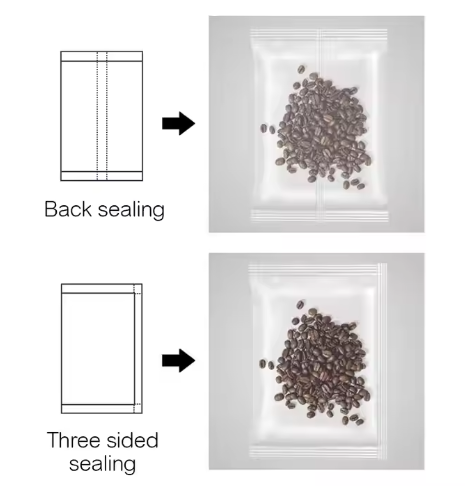

Sealing methods of Small granule quantitative packaging machine

The following are the common sealing methods of Small granule quantitative packaging machine and the corresponding approximate price range:

Heat sealing uses a heating device to heat and melt the edge of the packaging film, and then seals it through pressure bonding to form a firm seal. This method is suitable for a variety of plastic films, has good sealing, and is widely used in granule packaging. The price of entry-level heat sealing equipment is about US$300-800, and the price of mid-to-high-end equipment with temperature control and automatic adjustment functions is about US$800-1500.

Cold sealing uses special cold sealing glue to achieve sealing through pressure, which is suitable for granular products that have high requirements for packaging materials or are heat-sensitive. Due to the complex process and the involvement of special materials, the price of cold sealing equipment is usually between US$800 and US$2,000.