Fully Automatic Vertical Molding Soft Candy Packaging Machine Introduction

Wednesday January-28 2026 17:38:36

Fully Automatic Vertical Molding Soft Candy Packaging Machine performs metering, packaging, and sealing of soft candies. Because soft candies are sticky and easily deformed, manual handling can easily damage or cause them to stick together. The machine allows for controlled force and speed, reducing candy breakage. The machine packages 80 to 180 bags of soft candies per minute, meeting the needs of small-batch to high-volume tube packaging. In terms of materials, the parts of the machine that come into contact with the soft candies and packaging materials are made of food-grade stainless steel, which is rust-proof, wear-resistant, and easy to clean, meeting food production hygiene standards.

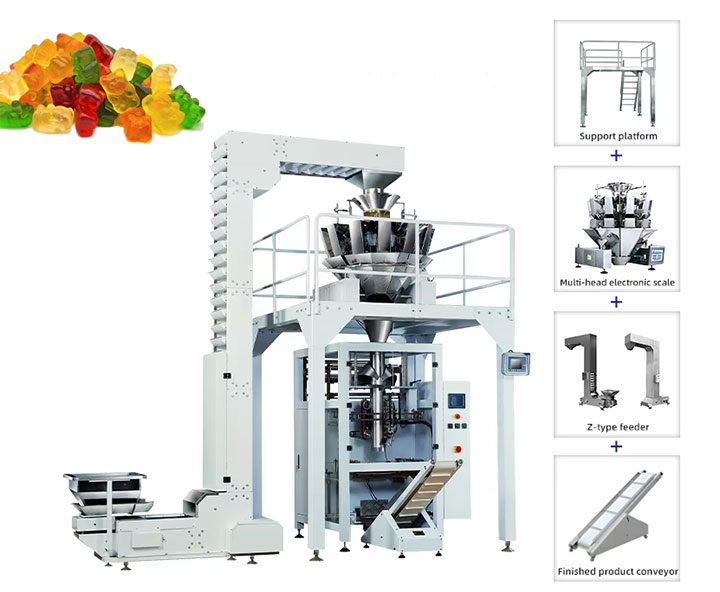

Components of the Fully Automatic Vertical Molding Soft Candy Packaging Machine

The Fully Automatic Vertical Molding Soft Candy Packaging Machine consists of a finished product conveyor belt, a Z-type feeder, a multi-head system, and a molding and packaging unit. The molding and packaging unit uses a vertical molding process, relying on precise temperature control and a specialized mold system to quickly shape and seal the soft candies. The Z-type feeder smoothly vibrates and transports the soft candy raw materials, while the multi-head electronic scale achieves high-precision synchronous metering down to the gram level, controlling the weight of each bag. The packaging process utilizes an adjustable bag maker and heat-sealing mechanism, adaptable to and capable of sealing various bag sizes. Finally, a finished product conveyor belt transports the packaged products out, connecting them to subsequent processes, ensuring fully automated operation.

Advantages of the Fully Automatic Vertical Molding Soft Candy Packaging Machine

Soft candies typically contain moisture and sugar, making them susceptible to moisture absorption, oxidation, or drying. The Fully Automatic Vertical Molding Soft Candy Packaging Machine controls the conveying, forming, filling, and heat-sealing of packaging materials, creating airtight individual packages that lock in moisture and flavor, extending shelf life. Manual packaging is slow, impacting soft candy production speed. The Fully Automatic Vertical Molding Soft Candy Packaging Machine can operate 24/7, significantly increasing production capacity. The machine is typically made of food-grade stainless steel, facilitating cleaning and sterilization, reducing the risk of microbial contamination, and meeting food production requirements. The fully automatic packaging machine can be integrated with upstream cooling and conveying equipment and downstream boxing, packing, and palletizing equipment to form a production line. Simultaneously, it can be easily integrated with coding machines or vision inspection systems to achieve product traceability and automatic quality rejection.

Fully Automatic Vertical Molding Soft Candy Packaging Machine Specifications

| Parameter Category | Parameter Item | Typical Specification/Description |

| Production Capacity | Packing Speed | 50 - 150 bags/minute (depending on product and bag type) |

| Packing Range | Bag-making Size |

Width: 50 - 150 mm Length: 70 - 200 mm |

| Applicable Products | Various soft candies, gummy candies, jellies, small granular candies, etc. | |

| Core System | Measurement Method | Multi-head computer combination scale (high precision, e.g., 8-14 heads) |

| Drive & Control | Full servo motor drive + PLC control + touch screen | |

| Packing Material | Film Roll Specification | Film roll outer diameter ≤ Φ400 mm, paper core inner diameter Φ76 mm |

| Sealing Method | Back seal (pillow bag), heat seal (adjustable temperature control) | |

| Equipment Requirements | Total Power | Approx. 3.0 - 4.0 kW |

| Air Supply Pressure | 0.6 - 0.7 MPa | |

| Overall Dimensions | Approx. 2500L × 1000W × 1800H mm |

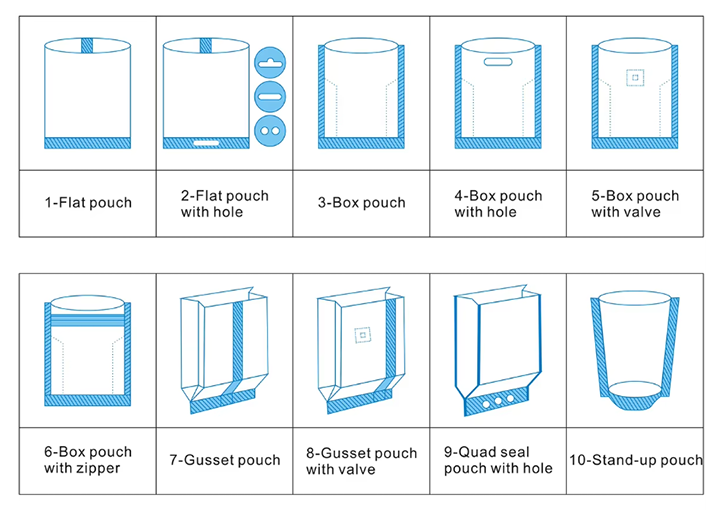

Fully Automatic Vertical Molding Soft Candy Packaging Machine Packaging Bag Types

The Fully Automatic Vertical Molding Soft Candy Packaging Machine is adaptable to various types of packaging bags, such as three-side seal and four-side seal bags. Furthermore, the machine is compatible with materials such as composite plastic film, aluminized film, and kraft paper composite film to meet the moisture-proof and oxygen-barrier requirements of soft candies.

Three-side seal bags are made by rolling the film into a tube, sealing it vertically on the back, and then horizontally sealing it on the top and bottom of the soft candy, forming a three-sided sealed structure. The bag is neat and can stand upright. Back-seal bags are the most basic type of vertical machine, with only a vertical seal in the center of the back and horizontal seals on the sides. Four-side seal bags use a dual-channel forming device or folding device to achieve four-sided sealing, resulting in a more robust structure suitable for packaging with double-sided printing. In addition, it can also produce zippered stand-up pouches. The machine embeds pre-made zippers into the bag opening and heat-seals them, allowing the bags to be repeatedly sealed and stand upright for better shelf display. It can also customize bags with easy-tear openings or hanging holes, simultaneously pressing out the easy-tear opening during horizontal sealing, or punching hanging holes at the bag opening for easy opening by consumers, making them suitable for hanging sales.

Case Study: Fully Automatic Vertical Molding Soft Candy Packaging Machine

A gummy candy company introduced three Fully Automatic Vertical Molding Soft Candy Packaging Machines for packaging products such as QQ candy and filled gummies. Previously, they used semi-automatic equipment with significant manual intervention, producing only 50,000 packs per day with a packaging error rate of 3.2%, resulting in high labor costs and low efficiency. The new equipment integrates a multi-head anti-stick combination scale and sealing system, automatically completing processes such as bag making, metering, filling, shaping, sealing, and coding. It is compatible with various packaging formats such as back-seal bags and pillow bags, and can control the filling amount to prevent gummies from sticking and breaking. After the upgrade, daily production increased to 62,500 packs, monthly downtime decreased to 8%, and only 3 workers were needed for feeding and inspection, resulting in reduced labor costs.

The Fully Automatic Vertical Molding Soft Candy Packaging Machine can package various types of gummies, including gelatin gummies, yogurt-coated gummies, fruit-filled gummies, pectin gummies, lava gummies, and starch gummies. The equipment supports multiple heating and cooling methods to ensure the gummies do not deform or stick together during packaging, guaranteeing quality and subsequent sales.