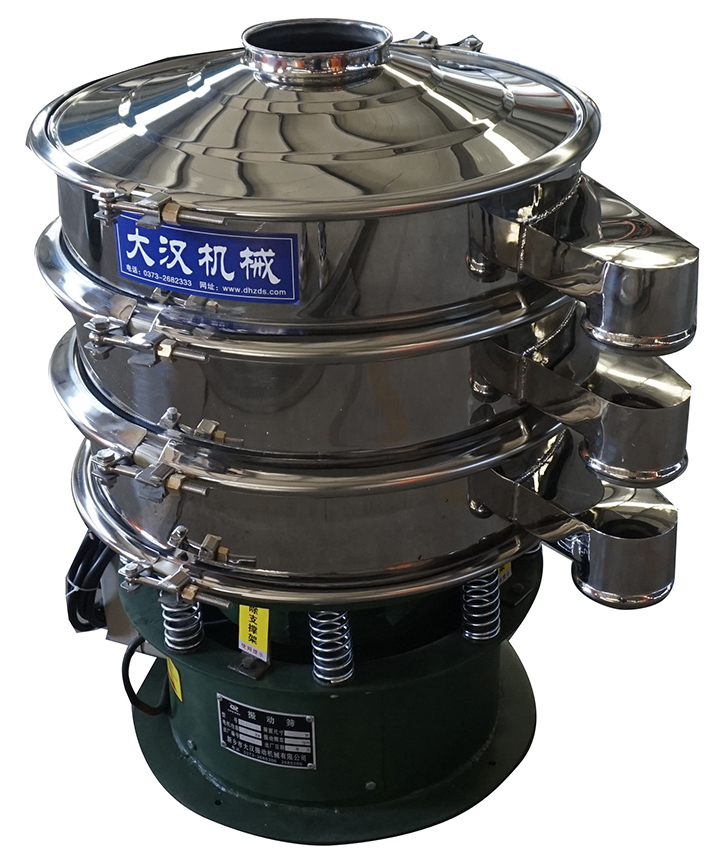

Sand Sieving Machine

Sand sieving machines, through the coordinated operation of a screening system and a drive system, efficiently grade and purify sand and gravel, meeting the particle size and purity requirements of various industries. They are widely used in applications requiring the grading, purification, or impurity removal of sand and gravel. Processing capacity: 5-500 m³/h Motor power: 1.5-30 kW Amplitude: 1-10 mm

What is a sand sieving machine?

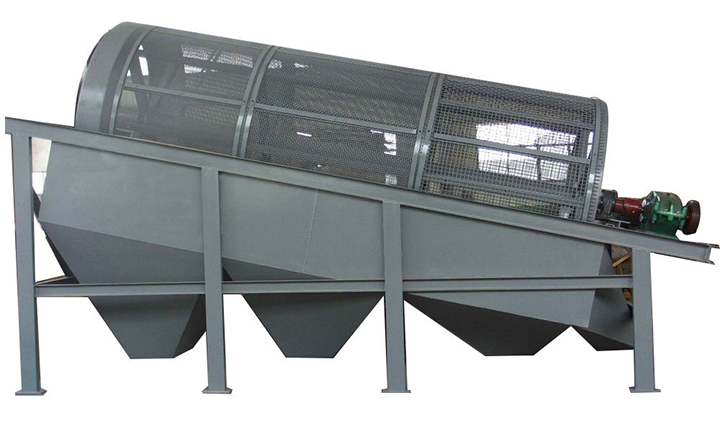

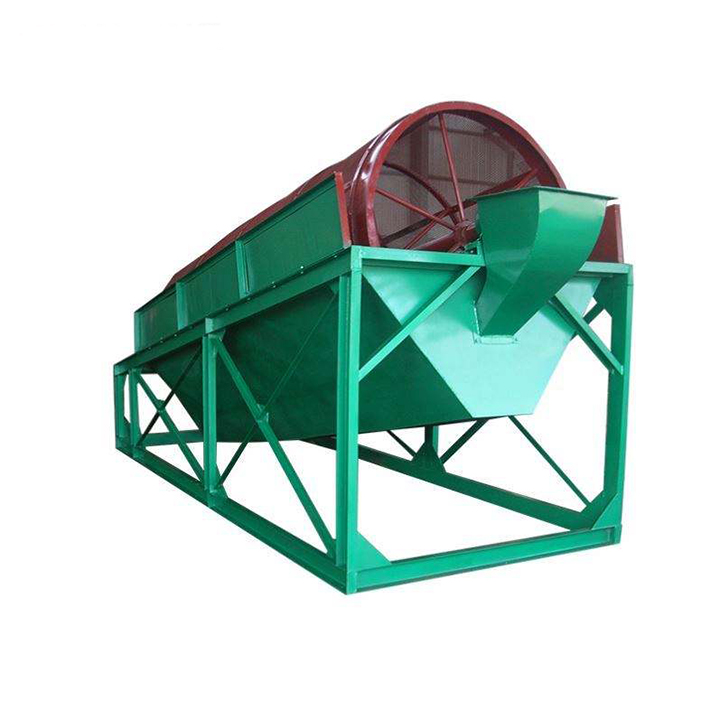

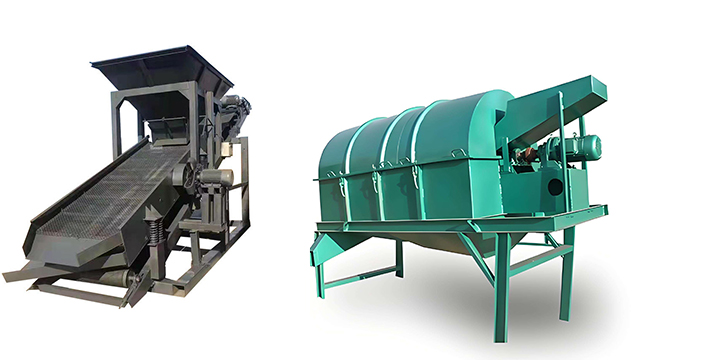

A sand sieving machine is a specialized device that uses mechanical power to drive a screen surface (or drum) to separate sand and gravel of varying particle sizes through the screening action of the screen surface. By setting the screen holes to a specific size, particles smaller than the size pass through the screen surface as the undersize fraction, while particles larger than the size remain on the screen surface as the oversize fraction, thereby achieving sand and gravel grading, purification, or impurity removal. It is a key piece of equipment in sand and gravel processing, construction, mining, and other fields.

How does a sand sieving machine work?

The operating principle of a sand sieving machine varies depending on the type of drive system. For example, a drum sand screen's motor drives the drum through a reducer (through a central shaft in shafted models, or rollers or gears in shaftless models), forcing material into the machine's feed port, where it tumbles and slides within the drum. A vibrating screen sand screen uses a vibrating motor (or exciter) to generate high-frequency vibrations, driving the screen box in linear, circular, or elliptical motions, causing the material to be thrown and bounced across the screen surface.

Under the power of the sieve, the material is constrained by the sieve's apertures and separated by its own particle size. Materials with a smaller diameter than the sieve's aperture are allowed to pass through, while materials with a larger diameter are restricted from passing through. This achieves material sieving and grading.

What is the composition of sand sieving machine?

Screen: The core equipment in the screening process, available in a variety of mesh sizes.

Power System: Vibrating (exciter motor, vibrating shaft, and exciter block), drum (motor, reducer).

Frame: Supports the equipment, ensuring sufficient strength and stability.

Inlet and outlet ports: Components that move materials in and out of the equipment.

What are the parameters of sand sieving machine?

|

型号规格 |

筛筒尺寸(mm) 可定制 |

处理能力 (m³/h) |

出沙口高度 (mm) |

电机功率 (kw) |

外形尺寸(mm) |

输送带 (mm) |

|

20型 |

Φ600*1500 |

30-40 |

1900 |

4.0 |

4300*1100*2300 |

500 |

|

30型 |

Φ900*3000 |

60-80 |

3200 |

5.5 |

8300*1900*3200 |

800 |

|

50型 |

Φ1000*3500 |

80-120 |

3500 |

7.5 |

9300*2100*3500 |

1000 |

What are the advantages of a sand sieving machine?

High Efficiency: It can operate continuously, with a single unit capable of processing several to hundreds of tons of material per hour (e.g., a small drum screen can process 10-30 tons per hour, while a large vibrating screen can reach 100-500 tons). It can also automate the feeding, screening, and discharging processes, achieving 24-hour continuous production. It is particularly suitable for large-scale sand pits, construction projects, and other applications that require batch processing of sand and gravel.

High Precision: The screen aperture specifications can be precisely customized to meet specific needs, allowing for precise separation of materials of varying particle sizes and precise adaptation to production requirements.

Adaptability: A wide variety of sand screens are available, adapting precisely to different screening scenarios and requirements. Drum screens are suitable for processing materials with high moisture content and prone to agglomeration (such as wet sand), as the drum's rotation prevents clogging. Vibrating screens offer higher screening accuracy and are suitable for applications with stringent particle size requirements (such as foundry sand screening).

Simple Operation and Maintenance: The equipment features a compact design and control systems, mostly push-button or PLC-based, making operation simple. Key components (such as the screen, motor, and bearings) are easily disassembled and replaced, and routine maintenance requires only regular inspection, lubrication, and cleaning of debris from the screen surface.

What are the applications of sand sieving machine?

As highly efficient sand and gravel separation and purification equipment, sand screeners are widely used in various applications requiring the grading, impurity removal, and cleaning of sand and gravel materials. Their core function is to separate or remove impurities of different particle sizes through screening to improve material purity. By grading, purifying, and reusing sand and gravel materials, they adapt to diverse needs and become a key device for improving material quality and production efficiency in various industries.

Construction and building materials industry: Sand screening machines are mainly used for screening and grading natural sand and gravel, construction waste, etc.

The water conservancy and road industry: Sand screens are screened to the particle size required for roadbed filling, dam construction, and other projects.

The mining and ore industry: Sand screens are screened to grade ores. Municipal Construction: Screening sand and gravel suitable for urban road maintenance, park landscape construction, and other projects.

Agricultural Industry: Screening fine sand and mixing it with organic fertilizer improves the aeration of clay soils.