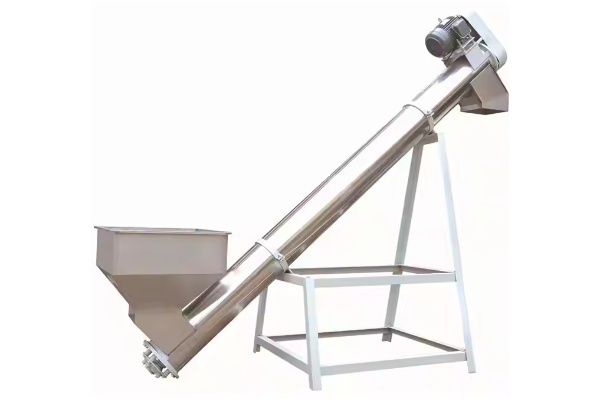

Kitchen waste screw conveyor

The price of a kitchen waste screw conveyor varies depending on its model, material, conveying capacity and other factors, ranging from US$210 to US$6,000.

Voltage: 220V, 380V

Conveying capacity: 500 liters/hour

Power: 2KW, 5KW, 15KW

Speed: 10-40 m/min

Thickness: 1mm-10mm/customized

Width: 500mm-1200mm/customized

What is Kitchen waste screw conveyor?

Kitchen waste screw conveyor is a conveying equipment designed specifically for the treatment of food waste. Its main function is to convey such materials with high moisture content, strong viscosity and possible debris in a closed and stable manner. Common types include shaft screw conveyors and shaftless screw conveyors that are more commonly used for food waste. Depending on the equipment model and configuration, the processing capacity of this type of conveyor is generally between several tons and tens of tons per hour, which can meet the needs of food waste treatment of different scales. The design of the equipment focuses on coping with the characteristics of food waste that are easy to rot, easy to entangle, and easy to clog, ensuring the smooth flow of materials within the treatment system.

When choosing a kitchen waste screw conveyor, you need to consider the particularity of the material and the on-site working conditions. First, the shaftless design can effectively avoid the common blockage problems of traditional shafted conveyors when handling viscous, high-water-content, and easily entangled food waste. Secondly, if horizontal transportation or short-distance lifting is required, a horizontal or small-angle shaftless conveyor can be selected; for large height difference lifting, a larger inclination conveying solution needs to be considered. Finally, in view of the corrosiveness and abrasiveness of food waste, stainless steel (such as 304 or 316L) should be used for spiral blades and U-shaped troughs, and ultra-high molecular weight polyethylene wear-resistant linings should be lined in the U-shaped trough to extend the life of the equipment and reduce maintenance requirements.

What are the common types of Kitchen waste screw conveyors?

Given the characteristics of food waste, Kitchen waste screw conveyors usually tend to choose shaftless screw conveyors,which makes the shaftless screw conveyor more advantageous than the traditional shafted screw conveyor:

U-Shaftless Screw ConveyorThis type is the mainstream choice in the field of food waste treatment. Its core feature is that there is no central shaft, but one or more thick spiral blades rotate inside the U-shaped trough. The inner wall of the U-shaped trough is usually paved with a wear-resistant lining (such as ultra-high molecular weight polyethylene) to reduce the friction between the spiral blades and the trough body and extend the service life.

Advantages: It can effectively convey food waste with strong viscosity, high moisture content, and easy entanglement, avoiding the blockage problem caused by the central shaft of the traditional shafted screw conveyor. At the same time, the fully enclosed U-shaped trough design also helps to control odor and prevent material leakage.

Horizontal Shaftless Screw ConveyorIt is mainly used to transport food waste over long distances on the same horizontal plane.

Advantages: The structure is relatively simple, the conveying is stable, and it is suitable for scenes that require a straight conveying path.

Inclined Shaftless Screw ConveyorWhen food waste needs to be lifted from a lower position to a higher position, an inclined screw conveyor is used. The inclination angle is usually between 0° and 30°, depending on the nature of the material and the lifting height.

Advantages: It can realize the lifting and transportation of materials, save space, and reduce the need for additional lifting equipment.

What are the advantages of Kitchen waste screw conveyor?

Due to its high moisture content, strong viscosity, complex composition and easy to rot, kitchen waste (kitchen waste) faces many challenges in the transportation process. In view of these characteristics, Kitchen waste screw conveyor shows its unique advantages, making it an indispensable key equipment in the kitchen waste treatment system.

Compact structure and high space utilization: Compared with other types of conveying equipment such as belt conveyors, screw conveyors have a more compact structure and a small footprint. This gives it a clear advantage in kitchen waste pretreatment workshops or transfer stations with limited space. Its flexible layout, such as horizontal, inclined or even vertical conveying (specific design), can better adapt to the needs of different process layouts and improve the space utilization of the plant.

Corrosion resistance and long life: The organic acids and salts in kitchen waste are corrosive to ordinary steel. Therefore, Kitchen waste screw conveyor usually uses high-quality stainless steel (such as 304 or 316L) as the main manufacturing material to enhance its corrosion resistance, thereby ensuring that the equipment can operate stably for a long time in a humid and corrosive environment, prolonging its service life and reducing the frequency of replacement.

Auxiliary functions during transportation: Some Kitchen waste screw conveyors can also realize some auxiliary functions while conveying, such as extrusion dehydration (through specially designed spiral blades or discharge port extrusion devices, preliminary solid-liquid separation of food waste is carried out to reduce the subsequent processing load) or preliminary crushing (in the process of conveying, some soft agglomerates or smaller lumps are simply crushed).

Basic parameters of Kitchen waste screw conveyor

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

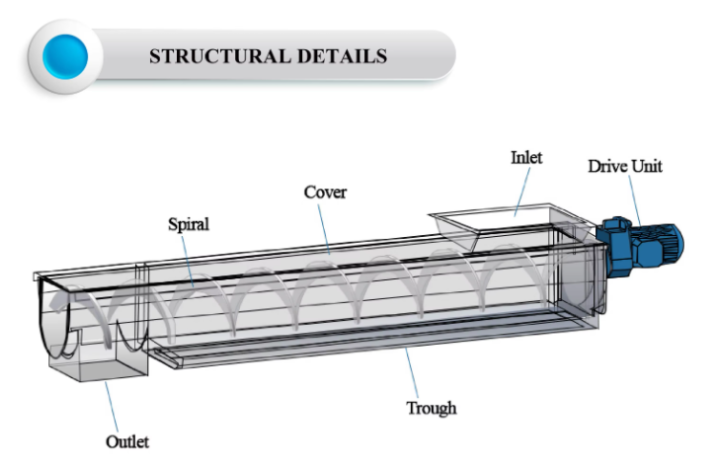

The structure of Kitchen waste screw conveyor

Kitchen waste screw conveyor usually refers to a shaftless screw conveyor, and its structural design mainly includes spiral blades, U-shaped trough, wear-resistant lining, drive device, and inlet and outlet.

Spiral blades: Kitchen waste screw conveyor has no central support shaft. The spiral blades are independent and connected to the motor through the drive end and rotate. The blade design is usually thicker and stronger than the blades of a shafted screw conveyor. It is often made of stainless steel (such as 304, 316L) or special wear-resistant alloy steel.

U-shaped trough: Most Kitchen waste screw conveyors use a U-shaped trough design instead of a closed round tube. This shape provides a larger space for material passage and facilitates the movement of materials without a central axis. The U-shaped trough is usually equipped with a removable cover plate to form a fully enclosed structure. The trough is usually made of carbon steel (anti-corrosion treated) or stainless steel.

Wear-resistant lining: The spiral blades produce friction with the bottom and side walls of the trough when rotating. The function of the wear-resistant lining is to protect the trough from wear and extend the life of the equipment.

Drive unit: usually consists of a motor and a matching reducer. The reducer is responsible for converting the high speed of the motor into the low speed and high torque required by the spiral blade.

Inlet and outlet: The feed port is usually designed in a funnel or rectangular shape to facilitate the smooth entry of food waste. Depending on the upstream equipment, the feed port may need to be specially customized to achieve seamless connection. The discharge port is usually located at one end of the conveyor, and the material enters the next processing link through the discharge port. The design of the discharge port needs to ensure that the material can be discharged smoothly to avoid accumulation.

What are the application scenarios of Kitchen waste screw conveyor?

Kitchen waste screw conveyor is mainly used in various scenarios of conveying wet, sticky, perishable and possibly sundry organic waste materials. These scenarios usually involve the centralized collection, pretreatment, transfer or subsequent processing of such special materials.

Material concentration and preliminary transportation: At the collection point or unloading area of food waste, the screw conveyor can lift and transport bulk food waste from the ground, hopper or collection container to the next processing unit. This includes conveying the garbage directly from the collection and transportation vehicles to the pretreatment equipment to achieve continuous feeding of materials.

Connection and transfer between process links: In the process of food waste treatment, it often includes multiple functional units, such as crushing, solid-liquid separation, fermentation, etc. The screw conveyor plays the role of a bridge connecting the units, and conveys the materials that have passed one treatment stage to the next treatment stage in a stable and closed manner. For example, the crushed food waste is conveyed to the solid-liquid separator, or the separated solid residue is conveyed to the anaerobic fermentation tank or composting area.

Conveying materials after solid-liquid separation: After the food waste is treated by solid-liquid separation equipment such as pressing or centrifugation, dehydrated solid phase (such as food waste residue) and liquid phase will be produced. Screw conveyors are particularly suitable for conveying this semi-solid, still sticky solid residue, and conveying it from the bottom or side of the separation equipment to the drying equipment, fermentation tank or other resource utilization equipment.

Kitchen waste screw conveyor manufacturer

Our Kitchen waste screw conveyor, with its shaftless design, can effectively solve many problems of traditional conveying equipment when dealing with viscous, high-water content and easily entangled materials. This means that easily entangled materials such as plastic bags and fibers will no longer be blocked or entangled on the shaft, significantly reducing the failure rate. In addition, the Kitchen waste screw conveyor is flexible in installation and can be designed for horizontal or inclined transportation according to site requirements to meet the needs of material transfer at different heights and distances. Whether it is transporting from the collection point to the pretreatment equipment or lifting the dehydrated materials to the high-level silo, it can be easily handled. In terms of material selection, 304 or 316L stainless steel is used as the core component, and the U-shaped groove is lined with ultra-high molecular weight polyethylene wear-resistant plate. In addition, the fully enclosed U-shaped trough effectively controls the spread of odor and material leakage. We can also provide customized production services, whether it is special conveying volume requirements, complex on-site space restrictions, or from the design of the inlet and outlet, the adjustment of the conveying length and angle, to the matching of the drive system, it can be configured according to the specific needs of the user.

Kitchen waste screw conveyor provides a specific and feasible solution for the transportation of materials in the current food waste treatment practice. When transferring food waste from one processing link to the next, it can effectively control the dissipation of odor and leachate, and maintain a clean working environment. Through the selection of equipment materials and structures, it can adapt to the complex physical state of food waste and support regular cleaning and maintenance to ensure the continuous and stable operation of the equipment.