Linear Sieve

The price of linear sieve usually ranges from $800to $5000/Set,varying depending on factors such as type (stainless steel, multi-layer, plastic, etc.), number of screen layers, processing capacity and material.

Processing particle size range:0.02-20mm

Moisture content adaptation:≤50%

Screen configuration:1-5 layers optional

Processing capacity range:0.2-50t/h

Vibration parameters:Vibration frequency 500-3000r/min

Screening accuracy:Screening deviation of the same batch of materials ≤2%

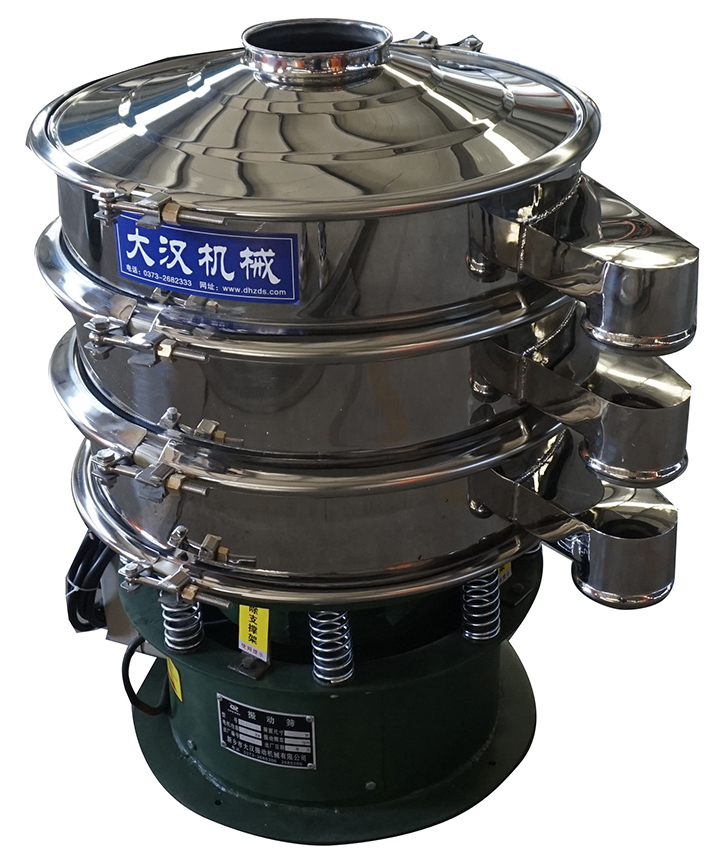

What is linear sieve?

Linear sieve is an efficient screening equipment with linear vibration as the core power, designed to solve the needs of graded screening of materials of different materials and forms. It adopts a modular vibration system, and by adjusting the vibration frequency (500-3000r/min) and amplitude (1-8mm), it can achieve accurate separation of 0.02-20mm materials, and is suitable for dry and wet mixed materials with a moisture content of ≤50%. The equipment supports multi-material customization and can be integrated with an intelligent control system. It is widely used in food, chemical, pharmaceutical, environmental protection and other fields.

The equipment supports 1-5 layers of screen configuration, and the single unit processing capacity covers 0.2-50t/h, and the price range is 800-5000 US dollars/unit. The fully enclosed structure with dust-proof design effectively controls dust leakage and meets the hygiene requirements of the pharmaceutical, food and other industries.

How many categories are there for linear sieve?

Based on the material characteristics, functional design and application scenarios, Linear Sieve can be divided into four categories: stainless steel type, air-cooled type, multi-layer type and plastic type. Each type has unique advantages in material, heat dissipation, grading ability or corrosion resistance.

Stainless steel linear sieve: It adopts a full stainless steel structure design. The material contact parts are made of 304/316 stainless steel (optional). After electrolytic polishing, it has strong corrosion resistance and can handle acidic and alkaline powders (such as citric acid and baking soda). It is suitable for screening food additives and pharmaceutical excipients. The mesh number is 2-400 mesh and the processing capacity is 0.5-30t/h.

Multi-layer linear sieve: It is equipped with 3-8 layers of screens (conventionally 5 layers), each layer has an independent discharge port, and can simultaneously complete the grading of 4-7 particle size grades. The mesh number of the screen increases from top to bottom, and the staggered arrangement design is adopted, which increases the material passing rate by 15%. Processing capacity 2-40t/h, suitable for industries requiring multi-level separation (such as flour grading, catalyst screening).

Plastic linear sieve: The sieve frame is made of reinforced PP (polypropylene) or PVC, and the screen is made of nylon 66 or polyester mesh. The overall weight is 60% lighter than the metal model and is resistant to acid and alkali corrosion (pH value 2-12). Suitable for screening corrosive materials such as electroplating waste liquid and pesticide intermediates, the working temperature is -10℃ to 80℃, and the processing capacity is 0.3-15t/h.

What are the advantages of linear sieve?

The performance advantages of linear sieve are as follows: it adopts equal frequency vibration technology, and the screening accuracy deviation of the same batch of materials is controlled within 2%, which meets the accuracy requirements of most production scenarios; it supports the replacement of screens of different materials such as metal, plastic, nylon, etc., and can adapt to the screening needs of various materials from ultra-fine powder to coarse particles; it can be equipped with a PLC control system, which can adjust the vibration parameters, cooling temperature and feed amount through linkage to adapt to the dynamic adjustment needs of complex production processes; the safety design covers different scenarios - the stainless steel model passes the food contact certification to ensure hygiene and safety, the plastic model complies with the RoHS standard to reduce the risk of harmful substances, and the air-cooled model is equipped with anti-scalding protection to reduce operational hazards, and the overall construction of a stable and reliable screening operation guarantee.

Linear sieve technical parameters table

| Model | Layer | Screening Area (mm) | Mesh Size (mesh) | Particle Size (mm) | Capacity (t/h) | Power (kw) | Vibration Direction Angle (°) | Screen Inclination (°) | Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

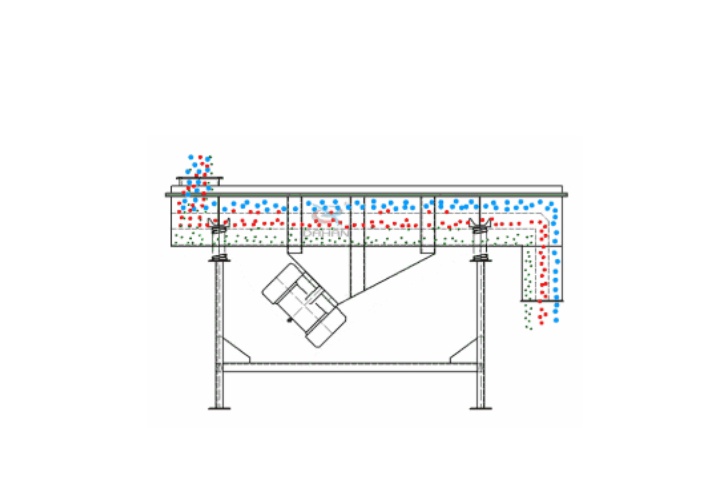

What is the working principle of linear sieve?

The working principle of linear sieve can be summarized as follows: the drive device drives the screen body to vibrate linearly and reciprocatingly. As the material moves forward with the vibration of the screen surface, particles smaller than the size of the screen hole pass through the screen and fall into the collection port below due to the vibration inertia, while particles larger than the screen hole remain on the screen surface and continue to move forward, and are finally discharged from the end, thereby achieving the separation of materials of different particle sizes.

What are the applications of linear sieve?

Linear sieve can be adapted to many different types of materials: the food field covers fine powders such as infant milk powder, pharmaceutical excipients, and seafood powder; the building materials industry involves high-temperature or fibrous materials such as cement clinker and glass fiber powder; the chemical scene includes solid particles and high-temperature resin particles recovered from electroplating sludge and acid and alkali waste liquid; in feed and ceramic processing, it is suitable for feed additives, ceramic powder and other multi-particle raw materials. For different materials, the equipment can achieve stable screening effects by changing the screen material (metal/plastic/nylon) and adjusting vibration parameters.

Linear sieve is a screening equipment with linear vibration as its core, which is dedicated to the precise classification of dry and wet materials with a particle size of 0.02-20mm and a moisture content of ≤50%. Its four major types specifically solve the pain points of the industry. The equipment has a screening deviation accuracy of ≤2% as its core advantage, supports PLC intelligent control and flexible switching of metal/plastic screens, and passes food certification, anti-scalding design, and RoHS standards to ensure safety in multiple scenarios. The working principle is that the vibration motor drives the screen body to move back and forth in a straight line, fine particles pass through the screen, and coarse particles are discharged at the end. It has now been maturely applied to the refined production processes in the fields of food (infant milk powder), chemical industry (electroplating sludge), building materials (cement clinker), etc.