Rotary Sieving Machine

A rotary sieving machine has a simple structure, primarily consisting of a drive system (motor, reducer), a rotating drum (containing the screen), a support mechanism, inlet and outlet ports, and other auxiliary components. Widely used in industrial applications requiring continuous, high-flow screening, it is a key piece of equipment for purifying and grading raw materials in industrial production. Motor power: 1.5-30kW (depending on model size) Speed: 5-30r/min Porosity: 30%-60% Material: Carbon steel (low cost) and stainless steel (corrosion-resistant)

What is a rotary sieving machine?

A rotary sieving machine is a type of mechanical device that uses rotational motion to grade and remove impurities from materials. A drive mechanism rotates the screen, causing the material to move across the screen surface. Due to the limited aperture of the screen, the material is separated by particle size, achieving the purpose of screening, grading, or impurity removal. Meeting production requirements for particle size and purity makes it a key piece of equipment in the material processing process.

How does a rotary sieving machine work?

The main body of a rotary sieving machine consists of a cylindrical or conical drum mounted at an angle (usually 3°-8°). Screens (or sieve plates) of varying apertures are fixed to the inner wall of the drum. During operation, a motor, via a reducer, drives the drum to rotate about its central axis. Material enters through the drum's upper feed port. Particles smaller than the mesh size pass through the screen and fall into a hopper outside the drum (becoming the undersize fraction). Particles larger than the mesh size continue to move toward the discharge end as the drum rotates (becoming the oversize fraction), ultimately being discharged from the lower end of the drum, thereby classifying materials of varying particle sizes.

What are the types and advantages of rotary sieving machine?

Rotary sieving machine can be categorized into different types based on their operating principles and structural features. Different screening equipment is suitable for different screening scenarios and solves corresponding material screening challenges:

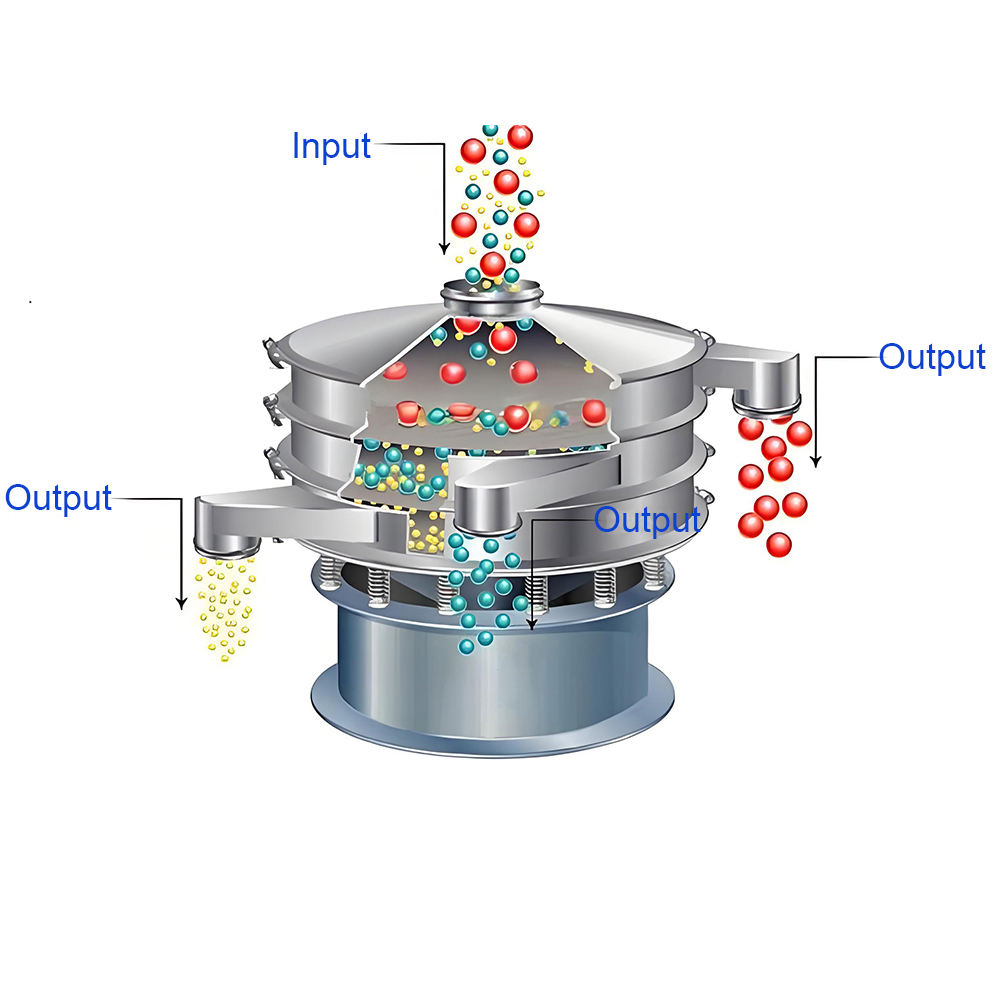

Rotary vibrating screen: A rotary vibrating screen is a high-precision, high-efficiency fine screening device that uses a vertical vibrating motor as the excitation source, with eccentric weights mounted at both ends. When the motor rotates, the eccentric weight generates centrifugal force, converting the rotational motion into complex vibrations in three directions: horizontal, vertical, and tilted. This vibration is then transmitted to the screen surface. Fine materials smaller than the mesh size pass through the corresponding mesh and are discharged from the lower outlet. Coarse materials larger than the mesh size are discharged along a trajectory from the upper outlet. This allows for material separation, grading, or impurity removal.

Advantages: Rotary vibrating screens offer high screening accuracy, enabling high-precision grading (down to 600 mesh). They can also support multiple layers of screens (typically 1-5 layers) to achieve multiple separations simultaneously. Rotary vibrating screens are core equipment for material purification and grading in fine processing. Their high precision and flexibility make them the preferred choice for industries with high screening quality requirements.

Spiral drum screening machine: A spiral drum screening machine uses a motor to drive the cylindrical screening drum through a reduction gear system. Material is placed into the drum through the feed inlet. The combined effects of the material's own gravity and the centrifugal force generated by the machine's rotation cause the material to move irregularly. Material smaller than the screen diameter passes through the sieve holes, while material larger than the sieve diameter remains in the drum. The two levels of material are discharged from their respective discharge ports, achieving material grading or screening.

Advantages: Spiral drum screens offer a wide screening range and can screen bulky, wet, sticky, or impure materials. They offer stable, efficient, and high-throughput screening capabilities, making them suitable for standardized production scenarios. Furthermore, this type of equipment consumes less energy, reducing operating costs, and the screen wears less frequently, extending its service life.

Centrifugal screening machine: A centrifugal screening machine uses high-speed rotating blades to generate centrifugal force, forcing the material toward the screen. Fine particles are then filtered based on the difference between the particle size and the screen hole diameter, completing the screening or impurity removal process. Centrifugal screening machines are particularly suitable for materials that are highly sticky and prone to agglomeration.

Advantages: Centrifugal screening machines are highly effective for screening powders with high fiber content, high viscosity, high humidity, static charge, or agglomeration. The centrifugal force breaks down material agglomerates, overcomes sticky adsorption, and solves the clogging problem of traditional screening. They offer high screening efficiency, stable screening, and simple operation.

What are the parameters of a rotary sieving machine?

| 型 号 | 功 率(KW) | 筛面直径 | 体 积 | 网层数 |

| 1SFAST-400-2S3S | 0.18 | Φ320mm | 580×580×560580×580×660580×580×760 | 123 |

| 1SFAST-600-2S3S | 0.55 | Φ550mm | 800×800×680800×800×780800×800×880 | 123 |

| 1SFAST-800-2S3S | 0.75 | Φ750mm | 900×900×780900×900×930900×900×1080 | 123 |

| 1SFAST-1000-2S3S | 1.47 | Φ950mm | 1160×1160×8801160×1160×10301160×1160×1180 | 123 |

| 1SFAST-1200-2S3S | 1.84 | Φ1150mm | 1360×1360×9801360×1360×11601360×1360×1360 | 123 |

| 1SFAST-1500-2S3S | 2.2 | Φ1450mm | 1850×1850×11301850×1850×13301850×1850×1550 | 123 |

| 1SFAST-1800-2S3S | 3.0 | Φ1750mm | 2200×2200×13602200×2200×14602200×2200×1680 | 123 |

What are the applications of rotary sieving machine?

Different types of rotary sieving machines offer different screening advantages and are widely used in various industries: Mining and metallurgy (spiral drum screening machines process ores with a particle size of ≤300mm; rotary vibrating screens are used for fine screening of metal powders); coal (drum screening machines screen and remove impurities from raw coal); chemicals and building materials (rotary vibrating screens screen and remove impurities from chemical raw materials; drum screening machines grade cement, lime, and other building materials); food and pharmaceutical industries (rotary vibrating screens grade and remove impurities from food raw materials and medicinal powders); daily chemical industry; and agriculture.