Flour Sieving Machin

A flour sieving machine separates flour into different grades based on processing requirements, meeting the quality requirements of subsequent food processing while removing impurities and ensuring flour purity. Its technical design balances screening accuracy, efficiency, and hygiene requirements, making it suitable for flour mills of all sizes (from small workshops to large automated production lines). Screening layers: 1-5 Screening efficiency: ≥95% Grading accuracy: Coarse fraction below the sieve ≤1%; fine fraction above the sieve ≤3% Material: Food-grade stainless steel

What is a flour sieving machine?

A flour sieving machine is a device specifically designed for flour sieving. It uses mechanical vibration or other power sources to force flour through sieves of varying apertures, achieving graded screening, impurity removal, and purification, effectively improving product quality and ensuring product purity. It can replace manual sieving, enabling continuous operation, improving production efficiency, and reducing labor costs. It is widely used in industries such as food processing.

How does a flour sieving machine work?

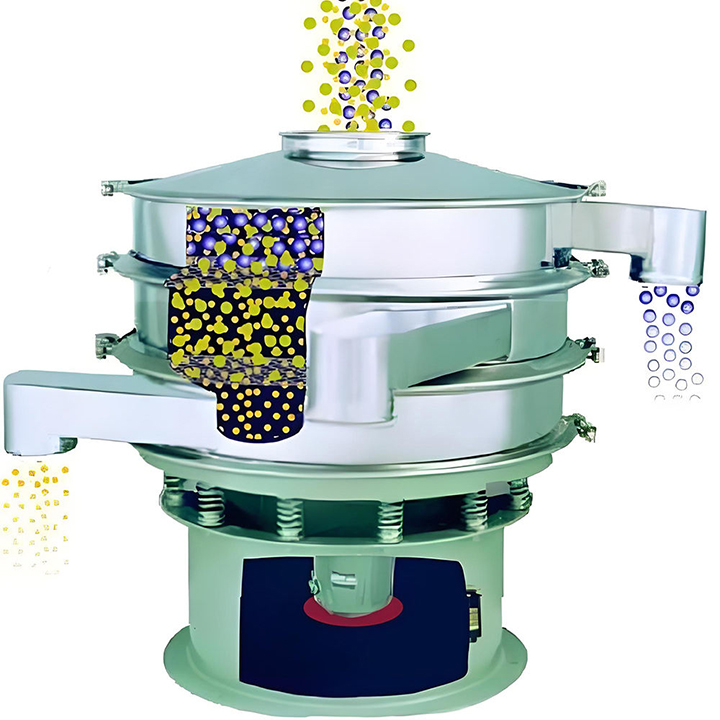

A flour sieving machine uses a vibrating motor to generate vibration, which drives the sieve, causing the material to move across the sieve surface. Due to the limited sieve aperture, flour with a smaller particle size passes through the sieve and is discharged through the lower sieve surface or the discharge port. Flour with a larger particle size is retained on the drying surface and discharged through the discharge port on the cover sieve surface. This achieves material grading or impurity removal.

What are the characteristics of the flour screened by flour sieving machin?

Easy to agglomerate: Flour powder has a small particle size and is hygroscopic, making it prone to clumping. Agglomerated flour can clog the sieve apertures, reducing screening efficiency. Furthermore, frequent machine downtime for screen cleaning may be required, presenting a significant hindrance to production.

High precision requirements: In the food processing industry, flour particle size grading requires stringent requirements. Flour is also light in texture and easily aerated during vibratory screening. Finer particles may float to the upper sieve for actual screening, resulting in reduced grading accuracy.

High flowability: Flour has a fine, fluid nature. Appropriate vibration parameters should be adjusted during screening to avoid excessively high vibration levels that cause powder to fly, or excessively low vibration levels that result in incomplete screening.

Large Processing Capacity: Flour production is often a large-scale operation, so continuous production, automatic discharge, and high throughput are ideal for screening processes to ensure efficient production.

What are the advantages and selection of flour sieving machin?

Given the characteristics and difficulties of flour screening, the primary consideration is how to accurately select the type of flour screening machine:

Inline Screening: The inclined screen surface and rapid discharge design of the inline screen effectively reduce material retention time on the screen surface, preventing accumulation caused by poor fluidity. The high vibration intensity effectively breaks up small agglomerates, and the large screen aperture reduces clogging, making it suitable for initial impurity removal. Most single-layer designs are primarily for coarse screening, resulting in relatively low screening accuracy. They offer high throughput per unit time and fast discharge speeds.

This type of screen is suitable for the early coarse screening stage of flour production, where high screening accuracy is not a requirement and large quantities of flour need to be processed quickly.

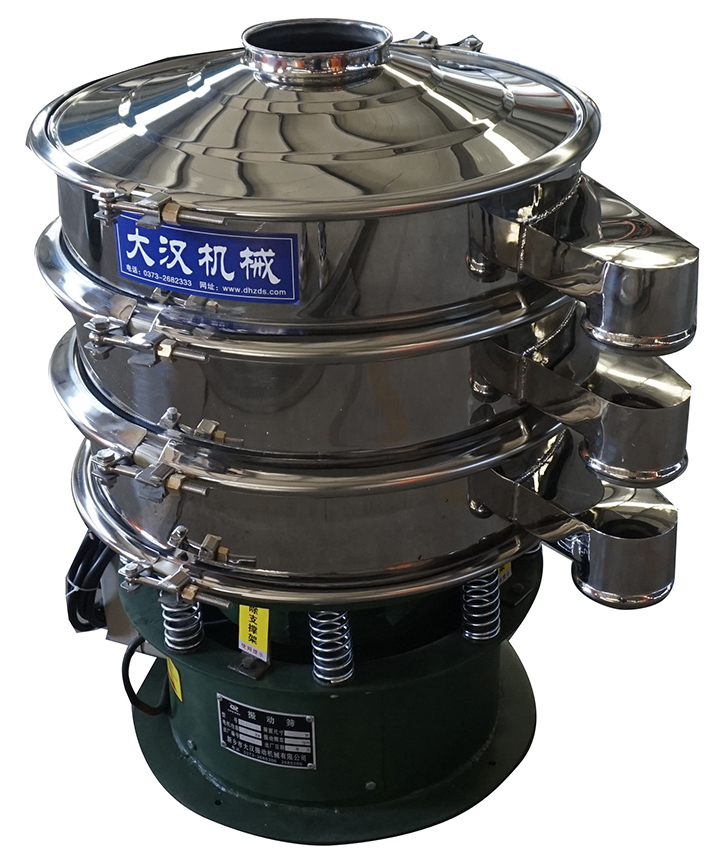

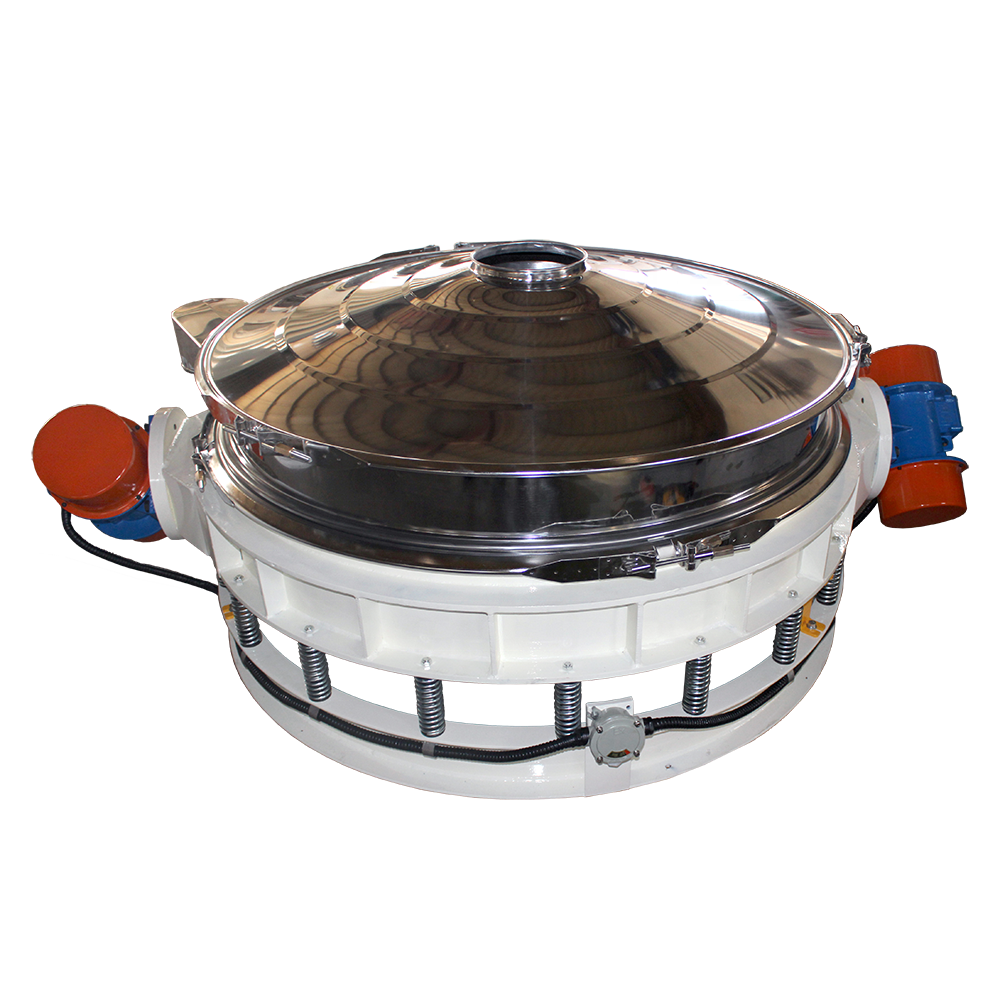

Rotary Vibrating Screen: A rotary vibrating screen uses a dual-axis vibration motor to cause the material to rotate in three dimensions on the screen surface (combined horizontal, vertical, and tilted motion). This allows for a long screening path and more uniform screening. It can be designed with multiple screens to achieve graded screening of different particle sizes, with high screening accuracy (capable of processing flour as fine as several hundred mesh). It offers excellent sealing to reduce dust, material waste, and environmental impact. It can also be equipped with a screen cleaning device to prevent screen clogging.

It is suitable for fine flour grading where high purity is required.

What are the core applications of a flour sieving machine?

Flour sieving machines are primarily used for flour sieving, grading, and impurity removal. They can effectively improve production efficiency, reduce labor costs, and ensure screening and grading accuracy, thus guaranteeing subsequent product quality. Flour sieving machines are also suitable for use in industries such as feed processing, chemicals, and pharmaceuticals.