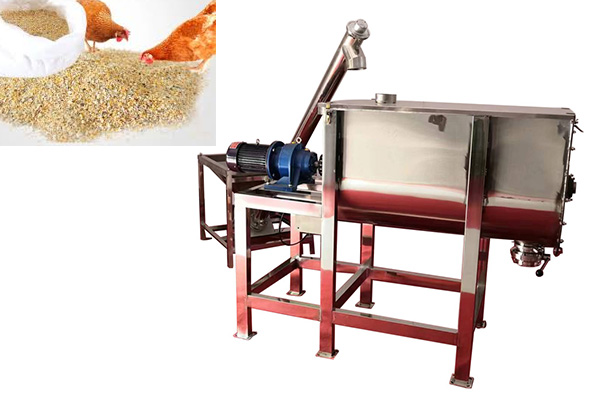

100kg Spice Horizontal Mixer

The 100kg spice horizontal mixer is designed to accommodate the lightweight properties of spice powders while also handling materials containing small amounts of liquid excipients. It achieves uniform mixing of different spice ingredients in a short time, making it widely used in spice production, food processing, and other fields. Capacity:100L Uniformity of Mixing:CV ≤ 5% Mixing Time:3-6 minutes Motor Power:Typically 1.5kW

What is a 100kg spice horizontal mixer?

A 100kg spice horizontal mixer is a horizontal device used to mix spices, capable of processing up to 100kg of spice at a time. The rotating agitator creates horizontal convection, shear, and diffusion motions in the spices, achieving uniform mixing. It meets food-grade spice hygiene standards and is equipped with an automated control system to minimize manual intervention. It is widely used in the food and chemical industries.

How does the 100kg spice horizontal mixer work?

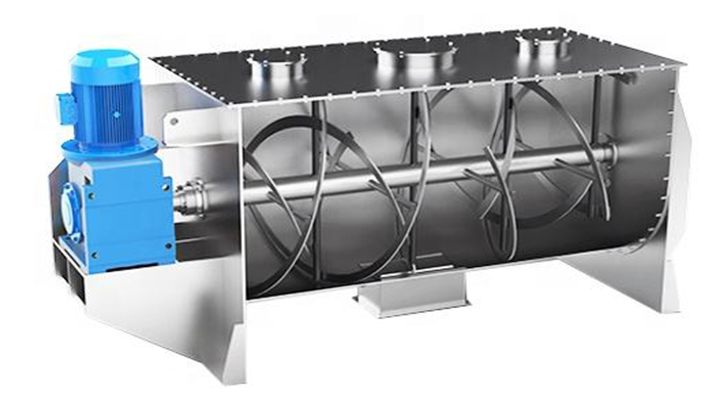

The 100kg spice horizontal mixer utilizes a rotating motor-driven stirring element within the horizontal tank, exerting a triple action of convection, shear, and diffusion on the spice raw materials. This promotes axial and radial flow, breaking up lumps and finely disintegrating the material to prevent uneven mixing. It is well-suited to the lightweight nature of spice powders and can handle materials containing small amounts of liquid excipients, achieving uniform mixing of different spice components in a short time. Furthermore, its food-grade materials and low-residue design ensure the purity and hygienic safety of the spices, making it a key piece of equipment for small- to medium-sized spice production.

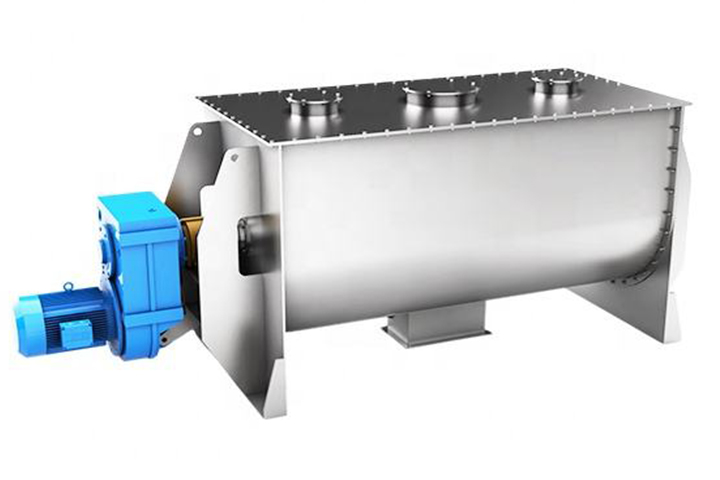

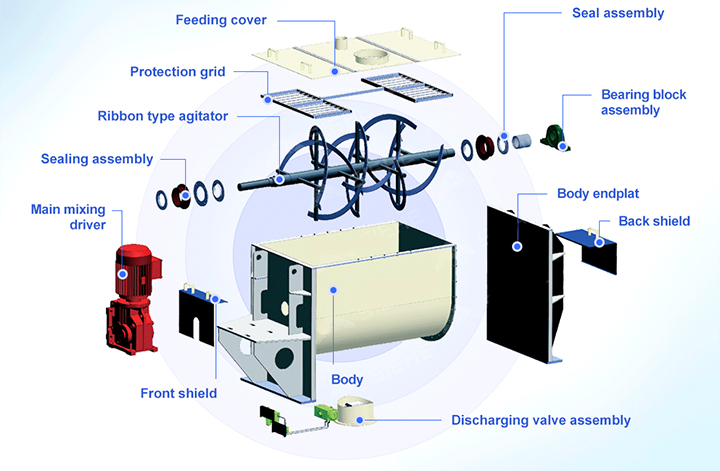

What is the structure of the 100kg spice horizontal mixer?

Body:The cylinder is a U-shaped or cylindrical horizontal cylinder welded from food-grade stainless steel with a mirror-polished interior to minimize spice residue and bacterial growth. The entire unit is sealed to prevent dust leakage and aroma volatilization.

Mixing System:The mixing shaft consists of one or two solid steel shafts running horizontally through the tank. The mixing elements are available in ribbon, plowshare (suitable for easily clumping spices), or paddle (suitable for mixing lightweight powders).

Power Unit:Consists of a motor, reducer, and coupling, providing power for the equipment.

Inlet and Outlet:The inlet is located at the top of the tank; the outlet is located at the bottom.

Control Box:Equipped with a touchscreen or push-button control cabinet, it allows for setting mixing time and mixing speed, and supports automatic start/stop and emergency stop functions.

Support Frame:A carbon steel or stainless steel frame located below the tank.

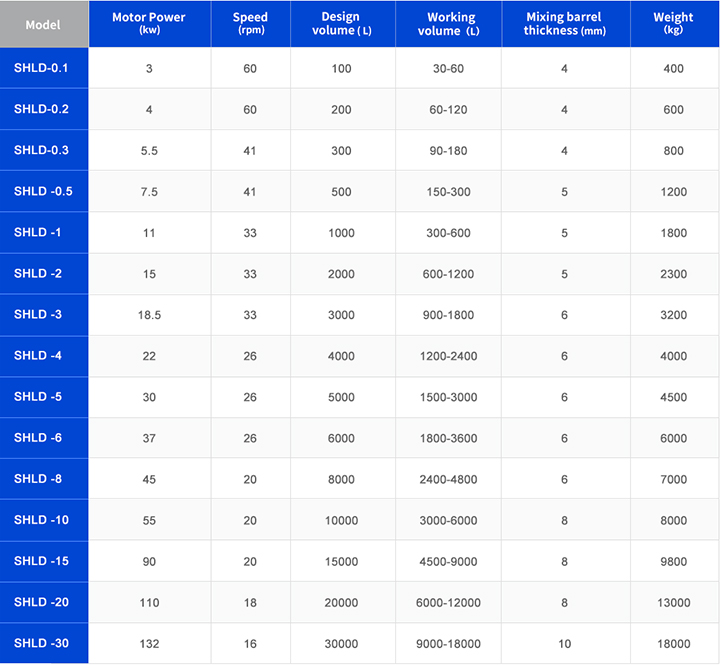

What are the parameters of a 100 kg horizontal spice mixer?

What are the advantages of a 100 kg horizontal spice mixer?

High Mixing Uniformity:The mixing uniformity (CV value) is ≤5%, making it particularly suitable for mixing multi-component, high-fiber spices.

Material:All parts that come into contact with the material are made of food-grade stainless steel (304 or 316), which is wear-resistant and corrosion-resistant.

Easy Operation:Supports variable frequency speed regulation and preset mixing times, meeting the needs of small and medium-sized continuous production.

Wide Compatibility:Capable of mixing pure powder spices or adding liquid additives via atomizer nozzles.

Low Energy Consumption:The low-power motor consumes less energy than large-scale mixing equipment, while maintaining high mixing efficiency.

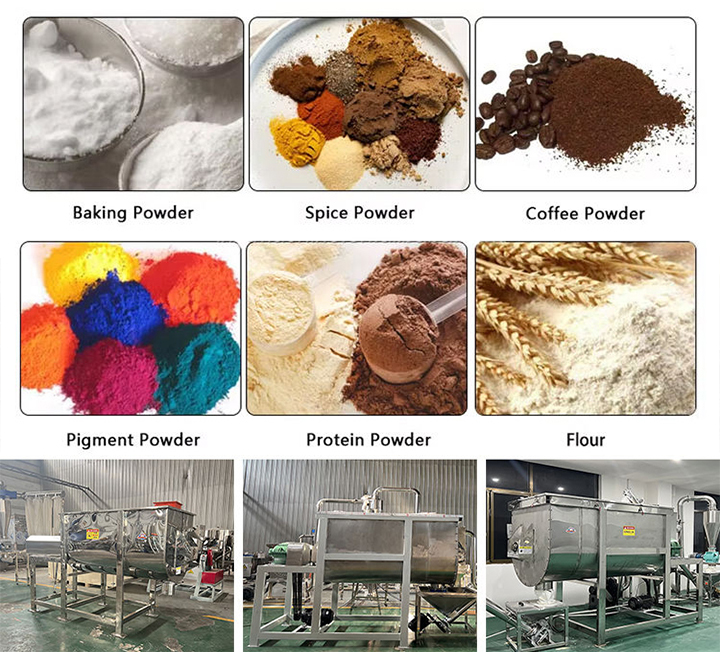

What are the applications of 100kg spice horizontal mixer?

The 100kg spice horizontal mixer is widely used in spice production, food processing and other fields due to its adaptability to small and medium batches, uniform mixing, and hygienic and safe characteristics. It is especially suitable for the diversified and customized needs of small and medium-sized enterprises:

Applications include preparing compound spices (five-spice powder, hot pot base spices, spices and additives), seasoning for baked goods (mixing spices with flour, sugar, milk powder, and other ingredients), marinating and seasoning meat products (mixing spices with salt, sugar, soy sauce powder, and other ingredients), stuffings (mixing chili powder, star anise powder, and ground meat), preparing compound seasonings (mixing spices with basic ingredients), and standardizing catering recipes (precise mixing ensures consistent flavor).

Related news

- Horizontal ribbon mixer manufacturer

- Horizontal Ribbon Blender Price

- Stainless steel animal feed horizontal ribbon mixer for feed additives

- What is a purpose of Horizontal Stainless Steel Ribbon Mixer

- Food Grade Spice Mixer

- Crushing and Mixing Machine Fertilizer Production

- Heavy-Duty Ribbon Blender Ceramic Powder And Glaze Mixing

- Pesticide Horizontal Mixer