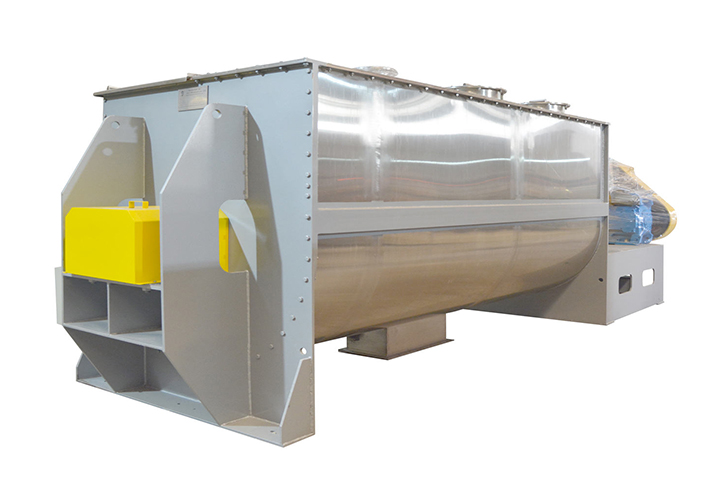

Food Grade Spice Mixer

Food grade spice mixers are widely used in seasoning factories, food processing plants, and catering central kitchens, providing core support for standardized food flavors. Capacity: 10-5000L Power: 0.25kW-18.5kW Speed: 11-17 rpm

What is a food grade spice mixer?

A food grade spice mixer is standardized mixing equipment designed specifically for the food processing industry. Based on materials and structures that meet food hygiene and safety standards, it achieves uniform mixing of various spices and seasonings through mechanical stirring, tumbling, or shearing. It is primarily used in the production of compound seasonings and food pretreatment.

How does a food grade spice mixer work?

Spices enter the mixer's sealed chamber through a manual feed port or an automated feeder. A motor drives the mixing and stirring elements within the chamber to rotate at high speed. By pushing, shearing, and tumbling the materials, the various spice types are thoroughly contacted, diffused, and blended within the equipment, achieving cross-mixing of the spices.

What is the structure of a food grade spice mixer?

Cylinder: A symmetrical "V"-shaped structure.

Spiral agitator: The core of the mixing process.

Drive system: Driven by a motor.

Inlet and outlet: The components that allow spices to enter and exit the equipment.

What are the types of food grade spice mixers?

V-type mixers: Suitable for mixing powdered or granular materials in the food industry, offering fast mixing speeds and suitable for mixing materials with varying specific gravities and high mixing efficiency.

Ribbon mixers: Suitable for mixing materials containing small amounts of liquid, offering high throughput and mixing efficiency. They are suitable for mixing spices with small specific gravity differences and ensuring a uniform mixing ratio.

Double-screw cone mixers: Minimize damage to fragile and heat-sensitive materials and are suitable for materials with large specific gravity differences and high viscosity. The conical bottom discharge design ensures thorough material discharge.

What are the advantages of a food grade spice mixer?

High mixing uniformity: The symmetrical "V"-shaped cylinder effectively prevents material accumulation. This is particularly suitable for spices with small specific gravity differences.

High mixing efficiency: Mixing spices in typical conditions takes only 4-10 minutes.

Simple structure and easy maintenance: The stainless steel main body is corrosion-resistant, reduces discharge residue, and can be rinsed directly with water.

Stable operation and low energy consumption: Driven by a motor and reducer, it offers low noise, low vibration, and lower energy consumption than some forced mixing equipment.

What are the parameters of a food grade spice mixer?

Maximum loading capacity: 40%-60%.

Mixing time: 4-10 minutes.

Dimensions:Small unit: 1600*1000*1500mm; large unit: 4000*2000*3000mm.

Weight:Small unit: 100kg-300kg; medium unit: 300kg-1000kg; large unit: 1000kg-5000kg.

What are the applications of a food grade spice mixer?

Food grade spice mixer is widely used in the field of food processing. Their core function is to evenly blend a variety of spices and seasonings in proportion through precise and hygienic mixing operations, providing a stable and consistent flavor for food, achieving standardization, scale, and hygienic safety of spice mixing, and providing a stable flavor foundation for compound seasonings, pre-prepared dishes, snack foods, etc. They are an indispensable key equipment in the industrial production of food flavors.

Related news

- What is a Food conveyor belt?

- How much does food packing machine cost?

- What are the categories of food packing machines?

- Food packing machine price

- Crushing and Mixing Machine Fertilizer Production

- Heavy-Duty Ribbon Blender Ceramic Powder And Glaze Mixing

- Pesticide Horizontal Mixer

- PVC Plastic High Speed Mixer