What is a purpose of Horizontal Stainless Steel Ribbon Mixer

Friday October-17 2025 11:04:17

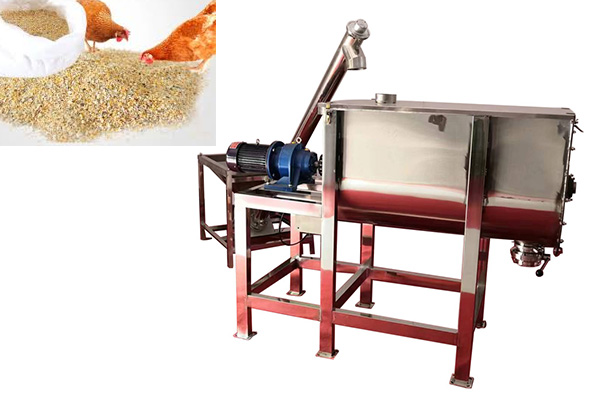

Horizontal Stainless Steel Ribbon Mixer purpose Use the Horizontal Stainless Steel Ribbon Mixer to mix various powders, powders and liquids, powders and granules, and dry solid materials. It is particularly good at dispersing and integrating sticky materials and materials that are prone to agglomeration. It is an effective and multifunctional mixer.

Application examples of horizontal stainless steel ribbon mixers in material mixing process

In many industrial production fields, such as food processing, pharmaceutical manufacturing, chemical industry and powder material processing, material mixing is a key process. Taking pharmaceutical powder mixing as an example, the production process usually includes raw material weighing → preliminary screening → mixing → granulation → tableting and other links. Among them, the horizontal stainless steel ribbon mixer is mainly used for the "mixing" link to ensure the uniform distribution of various powders or particles and to ensure the quality and stability of subsequent processes.

Process description:

Raw material preparation: Accurately weigh the powder or particle materials of each component according to the formula.

Pretreatment: Screen some materials to remove large particles or lumps to ensure the mixing effect.

Material mixing: Put the weighed materials into the cylinder of the horizontal stainless steel ribbon mixer in batches.

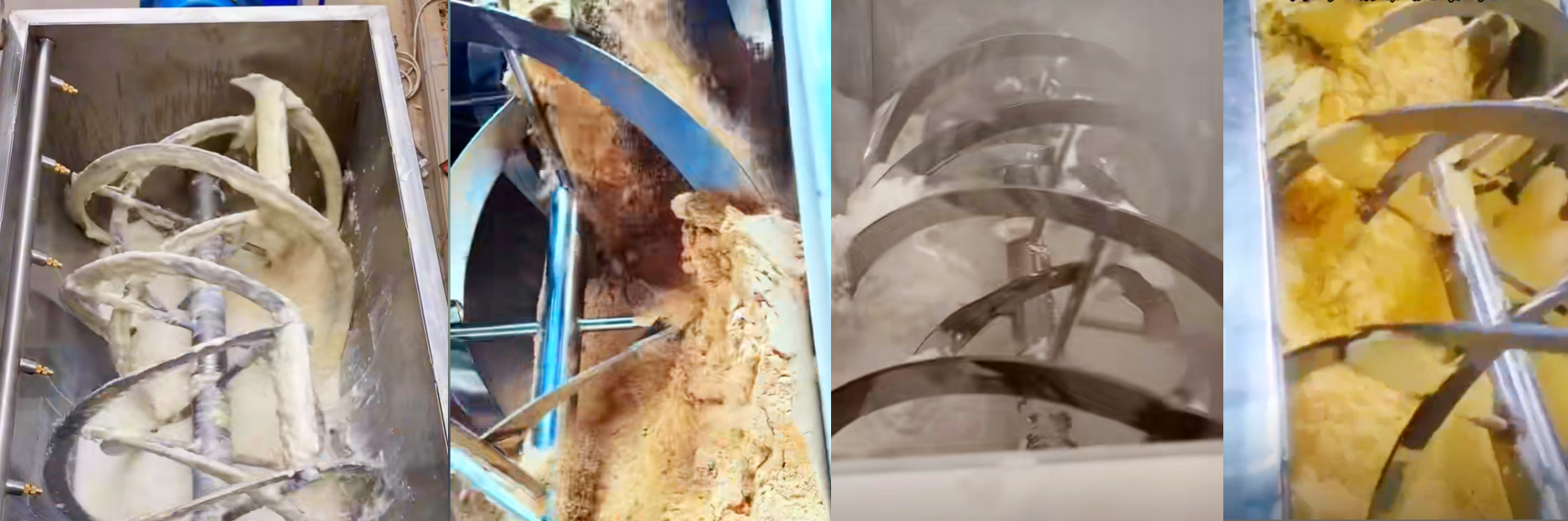

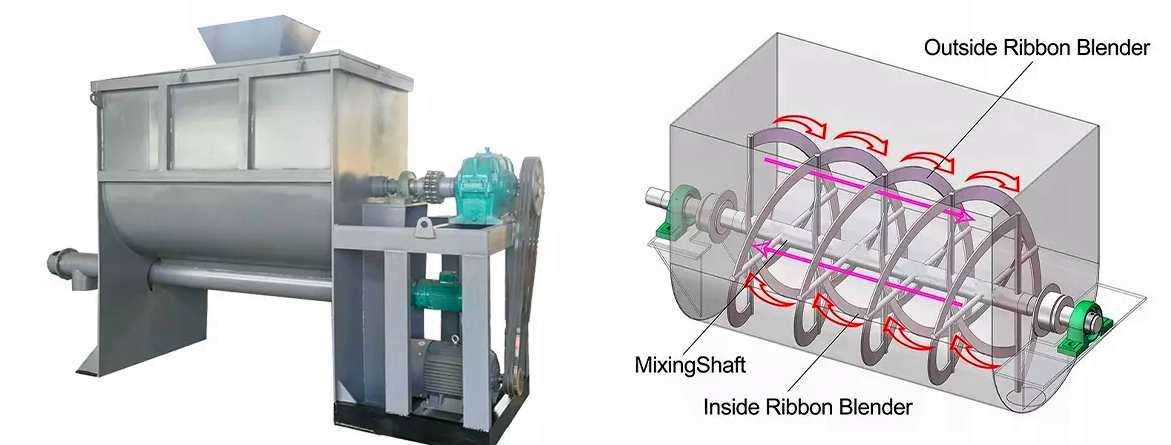

Mixing operation: Start the equipment, and the built-in double ribbon blades move in symmetrical and opposite directions to produce up and down and radial circulation, so that the materials are constantly turned over and mixed.

Mixing is completed: After a certain period of time, the mixer stops running, and the evenly mixed materials are discharged through the discharge port to enter the next process.

The specific role of the horizontal stainless steel ribbon mixer in the material mixing process

Even mixing: The double ribbon structure design pushes the material forward at one end and pulls the material backward at the other end to form a convection cycle, avoiding dead corners or stratification of the material, and achieving efficient and even mixing.

Protect material characteristics: The equipment is made of stainless steel to ensure food-grade or pharmaceutical-grade cleanliness requirements, and the mixing process is gentle and does not destroy the shape or properties of the material particles.

Strong applicability: It can handle materials in various forms such as powder, granular, and flake, and is suitable for mixing needs in various industrial fields.

Process adaptability Supports mixing of powder, granular, and paste materials (water content ≤30%), with adjustable speed (5-50rpm) to adapt to different material characteristics.

What is the use of horizontal stainless steel ribbon mixer?

Horizontal stainless steel ribbon mixer has a wide range of uses and plays a key role in the chemical, food, pharmaceutical, feed and other industries. In the chemical industry, it can efficiently mix pigments and resins to produce masterbatches with uniform color difference; in the food industry, flour, powdered sugar and additives can be mixed into baking powder with stable quality to ensure the consistent taste of the baked products; in the pharmaceutical process, it can gently mix drug particles and lubricants to ensure the integrity of the particles and meet the tablet content uniformity standards; in feed production, it can quickly and evenly mix bulk materials such as corn flour and soybean meal with trace vitamins to avoid nutritional grading.

The equipment not only achieves efficient mixing of materials of different densities and particle sizes, but also meets the stringent requirements of different industries for hygiene, efficiency and mixing uniformity, thanks to the corrosion-resistant and easy-to-clean properties of stainless steel, as well as the mixing principle of spiral ribbon convection and shear.

Application materials of horizontal stainless steel spiral ribbon mixer

| Flour | milk powder | sugar powder | starch |

| Cocoa powder | seasoning | spice powder | corn granules |

| Soybean powder | fish meal | vitamin powder | powder |

| Microcrystalline cellulose | slow-release agent | pigment powder | dye |

| Plastic additives | catalyst powder | cement powder | fly ash |

| Gypsum powder | mineral powder | fertilizer | seed treatment agent |

| Activated carbon powder | plastic powder | rubber powder | soil conditioner |

Case display of horizontal stainless steel spiral ribbon mixer

A large milk powder production enterprise uses a horizontal stainless steel spiral ribbon mixer to mix a variety of milk powder raw materials and vitamin additives. The bidirectional spiral blade design of the spiral ribbon mixer achieves uniform dispersion of the powder, avoids stratification and agglomeration caused by differences in material density, and ensures product quality stability and nutritional balance.

A pharmaceutical factory uses a horizontal stainless steel ribbon mixer to mix active drug powder and excipients. Since drugs have high requirements for mixing uniformity and cleanliness, the stainless steel material and closed structure of this model are selected to effectively avoid cross contamination and dust leakage. During the mixing process, the materials are evenly stressed, which prevents the breakage and performance changes of the active ingredients and ensures the consistency of the efficacy.

A paint manufacturer uses a horizontal stainless steel ribbon mixer to evenly mix a variety of pigment powders and additives to ensure the color uniformity and stability of the paint.

In short, the horizontal stainless steel ribbon mixer plays a key role in achieving uniform dispersion, protecting material quality and improving production efficiency in the material mixing process. It is an indispensable mixing equipment in modern industrial production.