Feed single shaft horizontal mixer

Through a stirring device, various powdered, granular or flaky feed raw materials and trace additives are quickly mixed and evenly mixed. It can be used to mix various types of feed such as premixes, concentrates, complete feeds, etc. The price ranges from $500.00 to $4,900.00

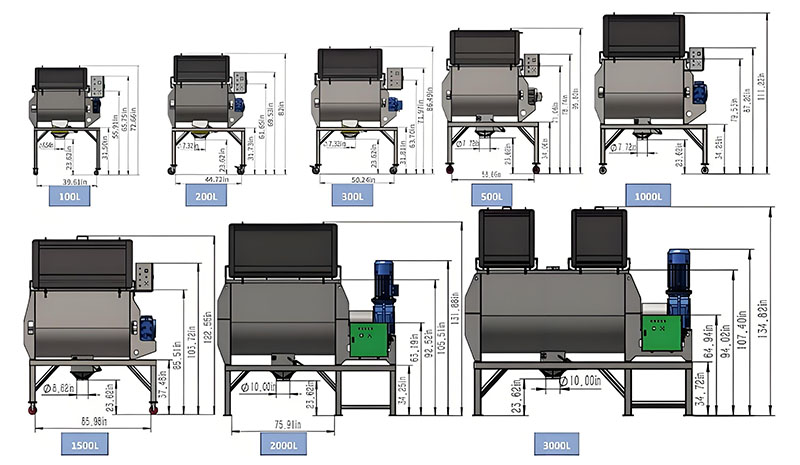

Mixing capacity per batch: 50-6000kg

Mixing time: 5-15min

Voltage: 380V/220V/450V

What is a Feed single shaft horizontal mixer?

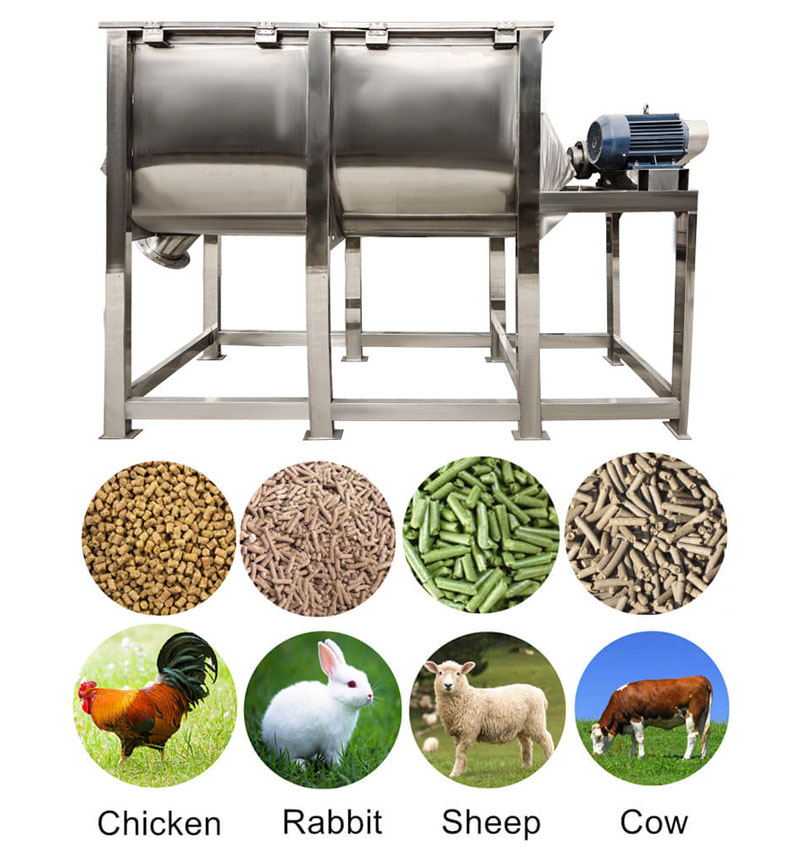

A Feed single shaft horizontal mixer is a mixer used for various feed processing applications. A single shaft drives a spiral blade or paddle to achieve uniform mixing of feed ingredients. It can thoroughly mix powders, granules, lumps, and compound feeds (such as grains, protein ingredients, and additives) with small amounts of oil or enzymes, according to the formulated ratio. This ensures a balanced nutritional profile in each portion of feed, thereby improving animal husbandry efficiency and growth quality. Each batch can mix 50 kg to 6,000 kg, and the mixing time is approximately 15 minutes.

A Feed single shaft horizontal mixer offers a capacity range of 1 to 10 cubic meters, meeting the needs of small to large feed processing plants. Available materials include 304 stainless steel and carbon steel. Customization is also possible based on the feed ingredients being mixed and the application requirements, such as adding wheels, a raised stand, or a sprayer.

What is the function of a Feed single shaft horizontal mixer?

In feed production, a single-shaft horizontal mixer ensures uniform mixing of feed ingredients, ensuring consistent nutritional content in each portion, improving palatability and digestibility. It also reduces raw material grading and prevents nutritional imbalances. Liquid additives (such as oils) can be added as needed to improve feed quality, reducing production costs and increasing efficiency. Mixing uniformity is a key indicator of feed quality, and a single-shaft horizontal mixer can easily achieve a mixing uniformity exceeding 93% (CV ≤ 7%), significantly exceeding traditional mixing methods.

What types of Feed single shaft horizontal mixers are there?

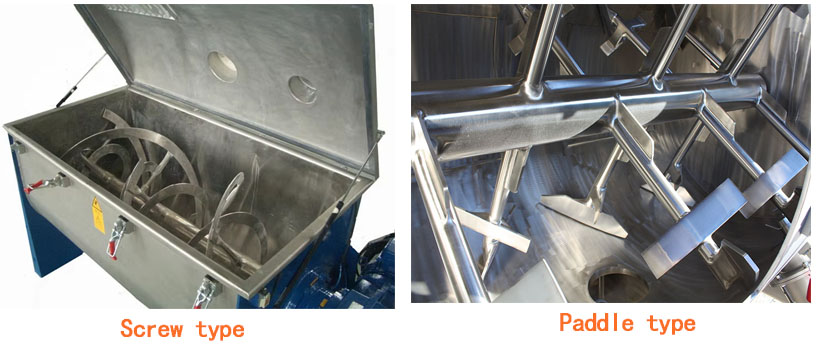

Feed single shaft horizontal mixers are categorized by blade type: ribbon and paddle. The appropriate model can be selected based on the type of feed being mixed and the intended application.

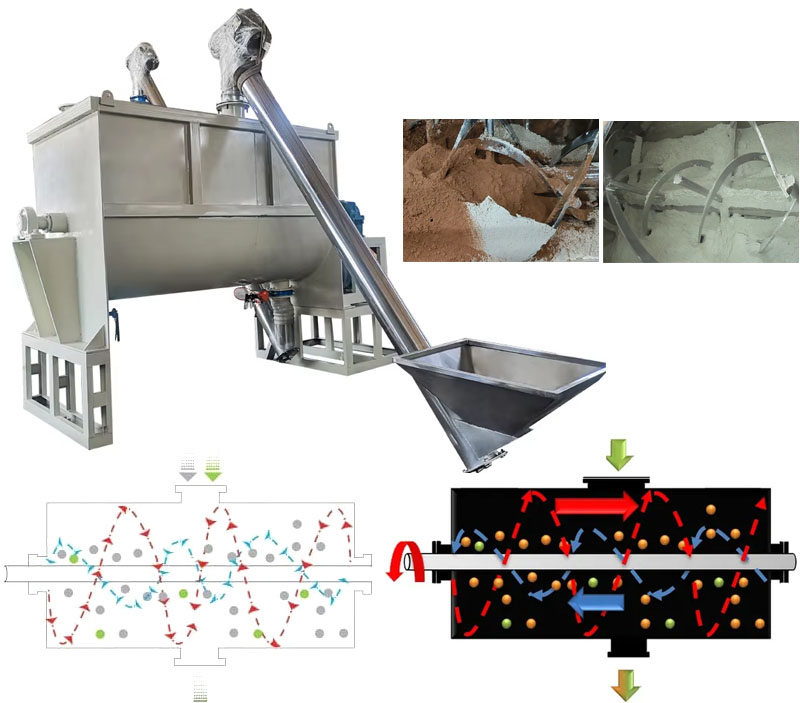

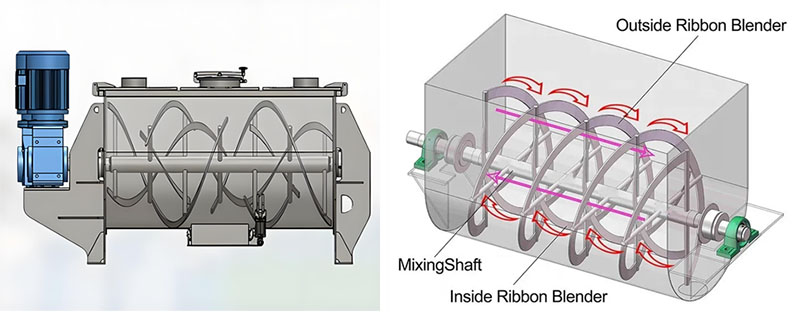

Ribbon-Type Feed single shaft horizontal mixer: Utilizing a double-layered ribbon design, the outer ribbon pushes the material inward, while the inner ribbon pushes it outward, achieving efficient mixing. Suitable for concentrated feed and complete powdered feed, it offers seamless mixing, minimal residue, and the ability to add liquids.

Paddle-Type Feed single shaft horizontal mixer: Equipped with specially designed impellers, it achieves high mixing uniformity (CV ≤ 5%10 or ≤ 7%), fast mixing speed, minimal residue, and the ability to add small amounts of liquid. Suitable for premixes (made of stainless steel), livestock and poultry compound feed, powders, granules, flakes, chunks, mixed materials, and viscous materials (when a small amount of liquid is required).

What types of materials can be mixed with a Feed single shaft horizontal mixer?

The physical properties of different feed ingredients vary significantly, placing varying demands on mixing equipment. Our Feed single shaft horizontal mixer efficiently processes a variety of feed materials, including grains, proteins, fibers, premixes, additives, and liquids:

Grain-based feeds: These include cereal grains such as corn, wheat, and sorghum (comprising 30%-60% of the feed formula). These materials have uniform particle size and good flowability, requiring sufficient contact with other ingredients during mixing. The equipment utilizes a spiral push mechanism to ensure uniform distribution of the grains and additives, preventing localized concentrations.

Protein-based feeds: High-protein materials such as soybean meal, rapeseed cake, and fish meal (comprising 5%-20% of the feed formula) tend to be dense and prone to sedimentation during mixing. Our equipment utilizes optimized blade angles to create a tumbling flow field, ensuring thorough integration of the protein ingredients and the base grains.

Fiber-based feeds: Crude fiber materials such as corn stover meal, hay meal, and bran (comprising 1%-25% of the feed formula) are prone to agglomeration and are difficult to process with conventional mixers. For this type of material, our Feed single shaft horizontal mixer can be equipped with specialized mixing blades with rectangular cutouts. Combined with a controlled wall clearance (5-10mm), this effectively breaks up fiber clumps and ensures uniform mixing.

Premixes and additives: Trace ingredients (typically less than 5%) such as vitamins, minerals, and pharmaceuticals require extremely high mixing precision. This equipment utilizes a 304 stainless steel mixing chamber and a low-speed mixing design (28 rpm) to ensure uniform dispersion of additives while preventing material denaturation caused by high-speed friction.

Liquid feed additives: When adding liquid ingredients such as oils and nutrient solutions to dry powder, a Feed single shaft horizontal mixer with a spray mechanism is recommended. This mixer utilizes a dust-screen-designed nozzle system to evenly distribute the liquid during mixing, preventing clumping and making it particularly suitable for producing high-energy feed.

Why choose a Feed single shaft horizontal mixer?

The Feed single shaft horizontal mixer utilizes either ribbons or paddles to achieve a mixing uniformity exceeding 93%, effectively ensuring balanced feed nutrition. It has a wide range of applications, processing dry powders, granules, and pastes, and can effectively mix liquid feeds with a liquid content below 70%. Compared to twin-shaft mixers, the single-shaft design offers a simpler structure, resulting in lower initial investment, lower maintenance costs, and lower energy consumption. It also minimizes material damage, with its gentle mixing action making it particularly suitable for handling delicate feed ingredients, avoiding nutrient loss due to excessive shearing. It also offers flexible adjustments, allowing for the addition of liquid addition systems and heating devices to meet diverse feed formulation requirements.

How does a Feed single shaft horizontal mixer work?

When a Feed single shaft horizontal mixer is in operation, the motor drives the main shaft through a reduction gear mechanism, and the agitating blades (paddles or ribbons) attached to the shaft begin to rotate. During this rotation, they continuously push the feed ingredients from both ends of the mixing chamber toward the center, simultaneously causing the feed ingredients to tumble up and down and left and right. This combined motion of convection, shear, and diffusion allows even ingredients with widely varying specific gravities and particle sizes to achieve highly uniform mixing in a short period of time.

Feed single shaft horizontal mixer Specifications

| Parameter items | 0.25 ton type | 0.5 ton type | 1 ton type |

| Cylinder size (length × width × High) | 2650×800×1800mm | 3200×1000×2000mm | 3400×1100×2000mm |

| Supporting Power | 4kW | 7.5kW | 11kW |

| Spindle Speed | 28 rpm | 28 rpm | 28 rpm |

| Mixing Uniformity | ≥98% | ≥98% | ≥98% |

| Single Mixing Time | 3-5 minutes | 3-5 minutes | 3-5 minutes |

| Equipment Weight | 600kg | 800kg | 1100kg |

| Material Options | Carbon Steel / 304 Stainless Steel | Carbon Steel / 304 Stainless Steel | Carbon Steel / 304 Stainless Steel |

| Discharge Method | Manual / Pneumatic | Pneumatic | Pneumatic |

| Liquid Addition System | Optional | Standard | Standard |