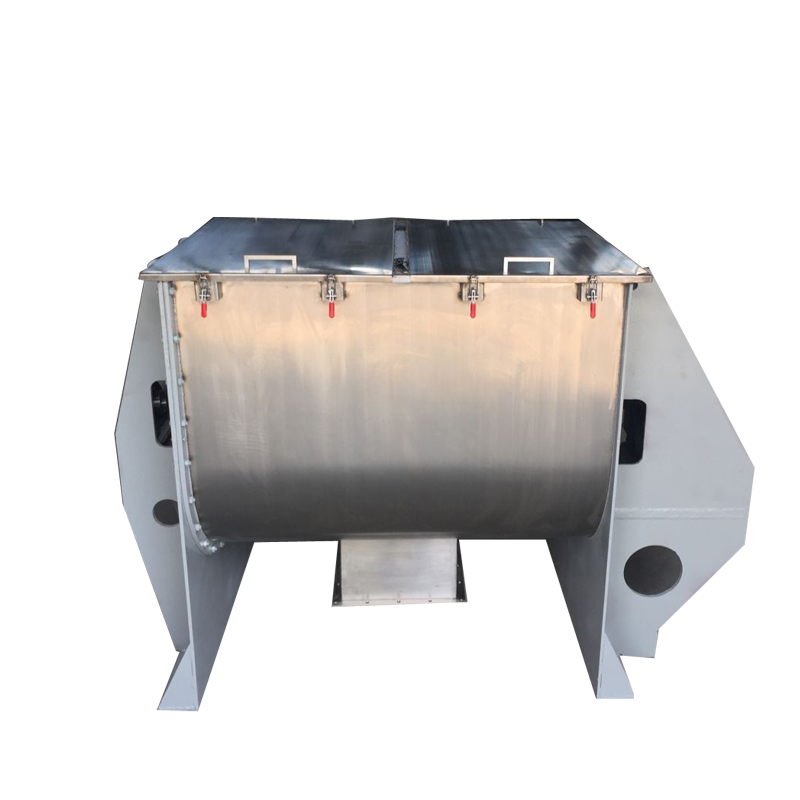

Fixed horizontal chicken feed mixer

Used for mixing powdered premixes, pellets, or chicken feed with added fat or liquid. Price ranges from $800.00 to $6,200.00

Mixing Volume: 100-6000 kg

Mixing Time: 8-20min

Voltage: 380V/220V/450V

What is a fixed horizontal chicken feed mixer?

A fixed horizontal chicken feed mixer is a feed processing machine with a fixed body and a horizontal mixing chamber. It is used to evenly mix various raw materials in chicken feed production. The rotation of an internal spiral belt or paddles quickly and evenly blends the various feed ingredients, ensuring nutritional balance in each batch and preventing uneven nutrient intake that can affect the growth of the chickens.

Fixed horizontal chicken feed mixers are primarily used in the feed preparation process for small and medium-sized chicken farms and feed processing plants. They can mix pellets, powders, premixes, energy feed (such as cornmeal), protein feed (such as soybean meal), and compound feed with vitamins, minerals, and other additives. The mixing capacity ranges from 0.5 to 5 tons per batch. The mixing time varies depending on the type and amount of material, but generally, uniform mixing is achieved in 5 to 15 minutes.

What types of fixed horizontal chicken feed mixers are there?

Fixed horizontal chicken feed mixers are categorized by mixing capacity into three types: small, medium, and large. The appropriate model can be selected based on the amount of chicken feed to be mixed and the application. Customized models are also available.

| Equipment Model (Vat Volume) | Maximum Single Mixing Volume (Dry Material, kg) | Hourly Production Capacity (Based on 80% Loading Rate, kg/h) | Applicable Scenarios |

| Small Fixed Horizontal Chicken Feed Mixer (500L) | 150-200L | 600-800L | Home chicken farm (500 chickens or less) |

| Medium-sized fixed horizontal chicken feed mixer (1000L) | 300-400L | 1200-1600L | Small and medium-sized chicken farm (500-2000 chickens) |

| Large fixed horizontal chicken feed mixer (2000L) | 600-800L | 2400-3200L | Large chicken farms (over 2,000 chickens) and feed processing sites |

What types of feed can a fixed horizontal chicken feed mixer mix?

A fixed horizontal chicken feed mixer can be used to mix powdered, granular, and mixed feeds commonly used in chicken farming, evenly blending all feed types.

| Feed type | Raw material composition example | Applicable flock stage | Mixing precautions |

| Powdered basic feed | Corn flour, soybean meal, bran, wheat bran, fish meal (powdered) | Chickens, young chickens, laying hens | Avoid moisture and clumping of raw materials; break up large chunks in advance |

| Pellets + powdered mixed feed | Pellets of corn, powdered soybean meal, powdered premix, shell powder (pellets) | Laying hens, broilers | Pellets should have a diameter of ≤5mm to prevent screw shaft jamming |

| Highly nutritious fortified feed | Basic powder + amino acids (powdered) + vitamin premix + salt | Laying hens at peak egg production and fast-growing broilers | Micro-ingredients (such as salt and premixes) should be premixed with a small amount of powder before adding to the equipment to avoid uneven mixing |

| Green feed mix | Chopped alfalfa and green leaves (≤3cm) + base powder | Free-range chickens and young chickens | Green feed should have a moisture content of ≤60% to prevent the feed from becoming too wet and clumping |

| Functional feed (such as disease-resistant feed) | Base powder + Chinese herbal powder (such as astragalus powder) + probiotic preparations | Flocks at various stages (as needed) | Functional ingredients (traditional Chinese medicine powder, probiotics) must be finely divided to avoid separation. |

What are the advantages of a fixed horizontal chicken feed mixer?

A fixed horizontal chicken feed mixer offers high mixing uniformity. The high-speed rotating blades within the horizontal mixing drum mix the feed in all directions and at multiple angles in a short period of time, ensuring uniform nutritional content in every grain. This is particularly suitable for chicken feed containing trace ingredients such as vitamins and minerals, ensuring their even distribution and providing precise nutrition for the flock. The mixer offers large capacity and high output, with a variety of sizes ranging from 1 cubic meter to 10 cubic meters. For example, the 5 cubic meter model can mix up to 3-4 tons of feed per batch, resulting in an hourly output of 10-15 tons. This fully meets the feed production needs of large-scale chicken farms, effectively reducing batch mixing and significantly improving production efficiency. The mixer is highly adaptable and compatible with a variety of feed types, whether dry powdered ingredients, semi-moist green feed, or feed supplemented with liquid nutrients. Its powerful mixing capacity easily handles a variety of complex formulas.

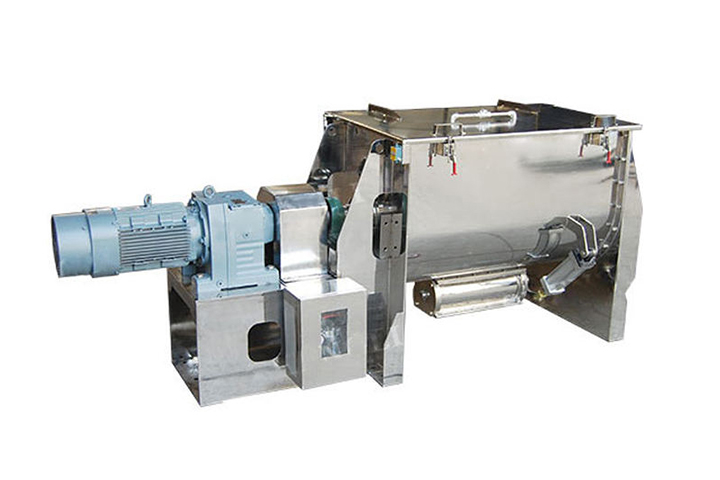

How does a fixed horizontal chicken feed mixer work?

When the fixed horizontal chicken feed mixer is operating, the chicken feed ingredients enter the horizontal mixing drum through the feed inlet. The mixing motor drives the mixing shaft at high speed, causing the mixing blades on the shaft to rotate accordingly. The unique shape and arrangement of the mixing blades create a complex motion path for the feed within the mixing drum, including axial displacement, radial tumbling, and circumferential rotation. These movements intertwine and mix the different feed ingredients until they reach a uniform consistency. The mixed feed is then discharged through the discharge port for distribution.

Specifications of Fixed Horizontal Chicken Feed Mixers

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

What are the applications of fixed horizontal chicken feed mixers?

Fixed horizontal chicken feed mixers are primarily used for processing chicken feed in small and medium-sized chicken farms, poultry feed processing plants, and breeding cooperatives. They can also be used in conjunction with small feed production lines to meet the needs of chicken farms of varying sizes. They can mix a wide range of chicken feed types, including powdered feed (such as a mixture of cornmeal and soybean meal), pelleted feed (granular feed that requires secondary mixing after crushing), and premixes (high-precision mixed feed with added trace elements and vitamins). They can also mix compound feeds containing green feed shreds and mineral additives, meeting the feed needs of chicks, layers, and broilers at different growth stages.

Fixed horizontal chicken feed mixer example

| Application scenarios | Mixed materials | Single mixing volume | Mixing time |

| Large chicken farms | Powdered main ingredients (corn, soybean meal, etc.), trace element additives, and a small amount of oil | ≥2 tons | 15-20 minutes |

| Small and medium-sized farms/specialized farmers | Dry powders, pellets, premixes, concentrates | 500 kg | 3-6 minutes |

| Feed processing plant | Various grains, meal, vitamin, and mineral additives | 1000 kg (1 ton) | 3-6 minutes |

| Home farming | Custom-mixed powdered feed, small amounts of premixes | 250 kg | 3-6 minutes |

| Aquaculture Cooperative | Corn, bran, soybean meal, trace additives, oils and fats | 500 kg | 3-6 minutes |

| General Farm | Dry powder, liquid additives (such as oils and fats) | 1000 kg (1 ton) | 3-6 minutes |