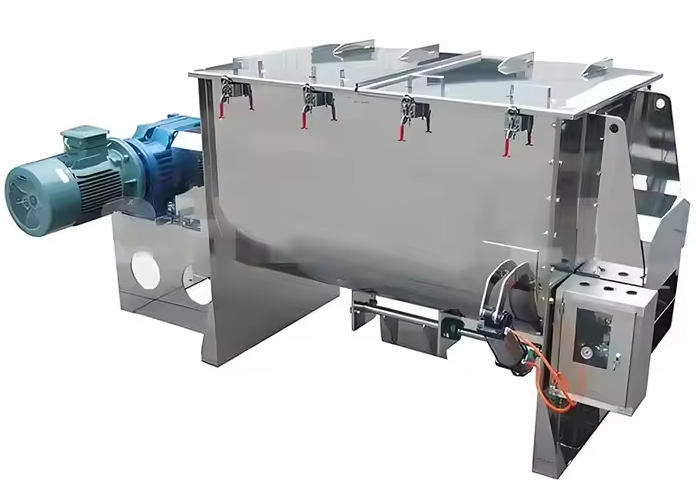

Pesticide Horizontal Mixer

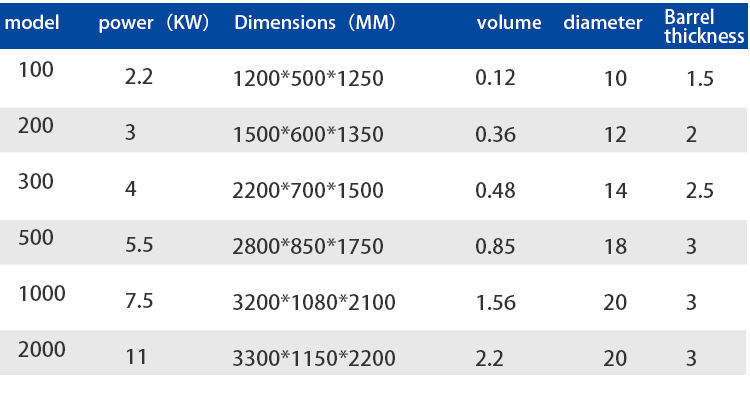

Pesticide horizontal mixers can accommodate a variety of material forms, including powders, granules, solids, liquids, and viscous materials, meeting the complex raw material combinations required in pesticide production. Capacity: 0.25m³-10m³ (customizable) Motor Power: 3-5.5kW for small units, 45-75kW for large units (A 1m³ unit typically uses a 7.5-15kW motor) Speed: 15-30 rpm Mixing Methods: Double blade type, spiral type, etc

What is a pesticide horizontal mixer?

A pesticide horizontal mixer is a horizontal mixing device used in pesticide production or processing. Its primary function is to uniformly mix different agricultural raw materials, ensuring uniform composition, stable performance, and meeting required quality standards. Pesticide horizontal mixers are commonly used in large-scale batch production and can accommodate the mixing of various raw materials, offering high efficiency and stable results.

What is the working principle of pesticide horizontal mixer?

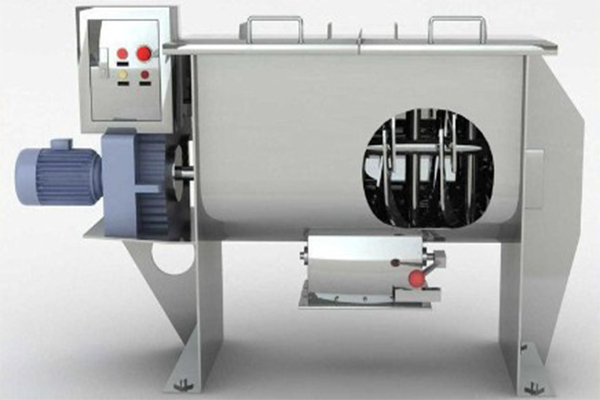

A horizontal pesticide mixer uses a stirring mechanism within a horizontal container to mix the materials fed into the container through convection, shear, and diffusion mixing. This ensures thorough mixing of the materials, achieving a uniform state. The mixed, homogeneous material is then discharged from the discharge port.

What are the relevant parameters of pesticide horizontal mixer?

What are the characteristics of pesticide horizontal mixer?

Excellent Mixing Effect and High Efficiency: The horizontal pesticide mixer's structural features allow the stirring mechanism to fully cover the entire cylinder volume, ensuring more thorough and uniform mixing of agricultural materials. A variety of cylinder capacities are available, enabling continuous batch production for medium and large-scale operations and improving production efficiency.

Easy Operation: The horizontal pesticide mixer can be equipped with a timing control function or an integrated PLC control system for semi-automated or automated operation, significantly improving ease of operation and production efficiency, making it suitable for large-scale production.

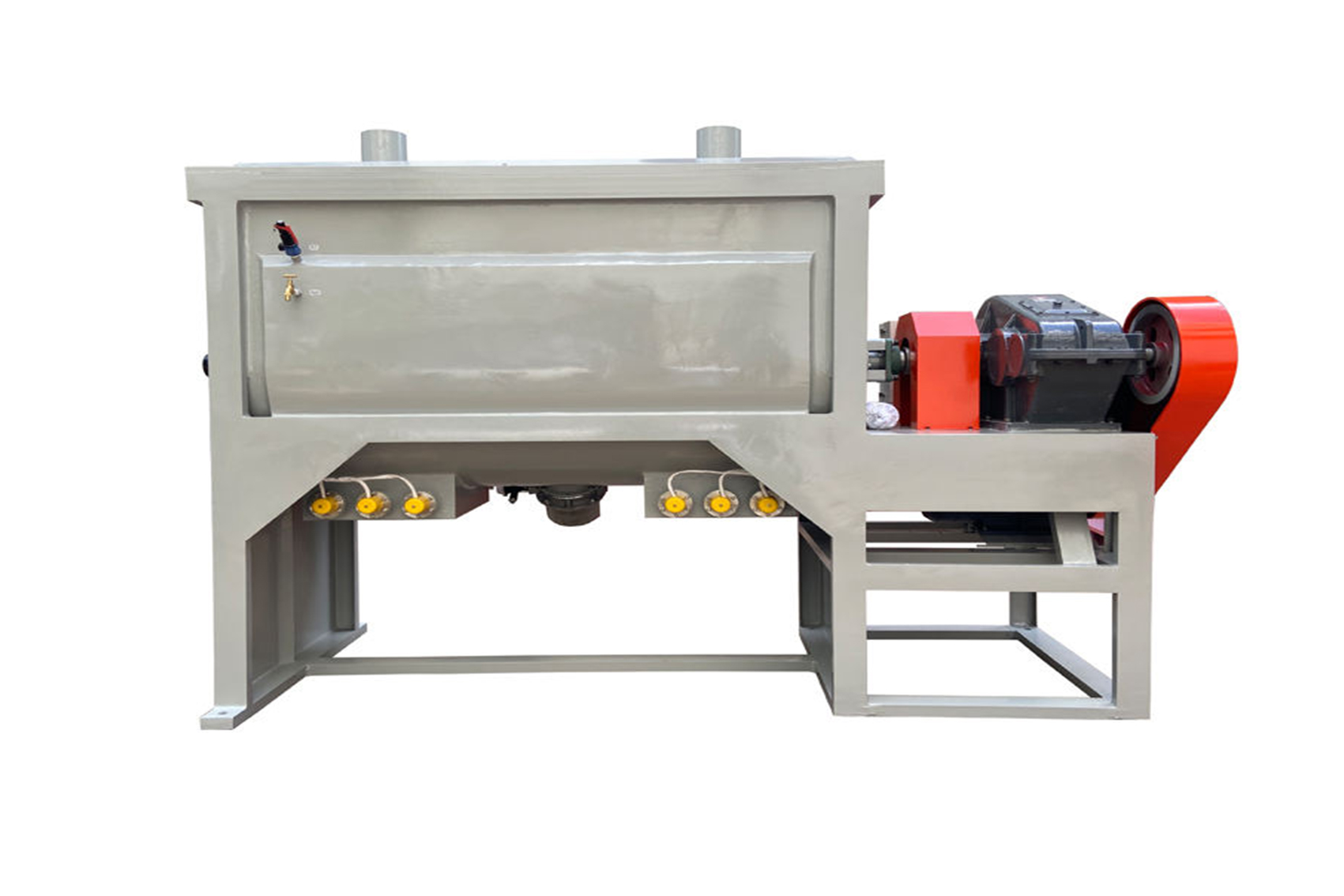

Stable and Durable Operation: The horizontal pesticide mixer's horizontal cylinder structure ensures stable operation, with low vibration and noise, ensuring continuous and stable operation during production. Key components are made of wear-resistant and corrosion-resistant materials such as stainless steel, reducing equipment wear and extending its service life.

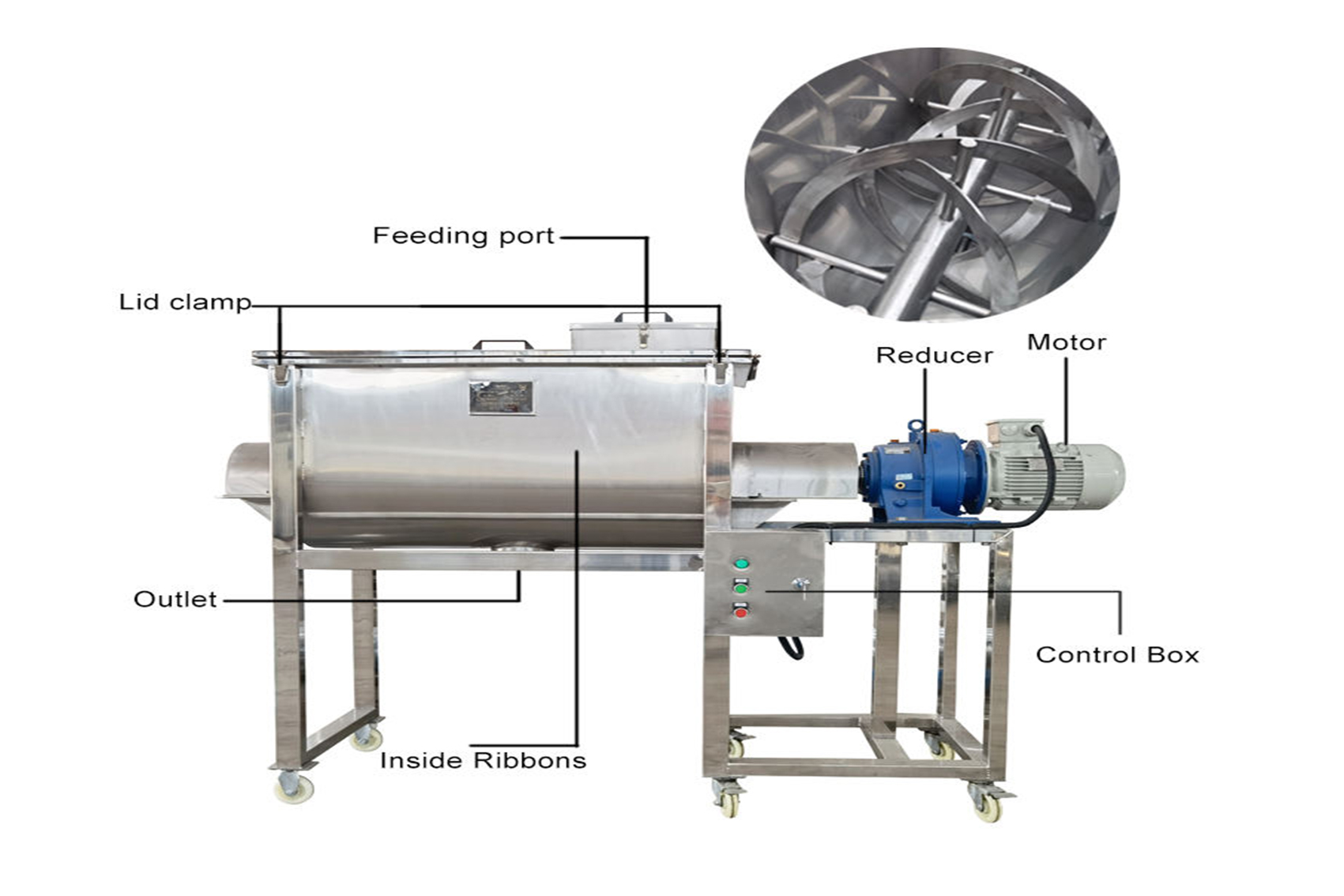

What are the components of a horizontal pesticide mixer?

Inlet and Outlet: The inlet is located at the top or end of the cylinder, while the outlet is located at the bottom or side.

Motor: The power source.

Reducer: Connects the motor and the main shaft.

Coupling:Connects the reducer output shaft to the agitator shaft, transmitting power.

Cylinder: Typically a long, U-shaped or round cylinder.

How to choose a horizontal pesticide mixer?

Material Handling Capacity: Select a motor with the appropriate capacity and power based on the amount of pesticide raw materials to be mixed.

Twin-Blade Mixer: Ideal for applications requiring high mixing uniformity, high throughput, and fast discharge. It is easy to clean and has low energy consumption.

Screw-Ribbon Mixer: Optimized for mixing pastes and highly cohesive materials. It is suitable for high throughput and a certain mix type (due to the complexity of cleaning, it is suitable for mixing viscous materials).

Material: For highly corrosive materials, choose a mixer made of high-grade stainless steel or one lined with a corrosion-resistant coating. Generally, ordinary stainless steel is suitable.

What are the applications of pesticide horizontal mixer?

Pesticide horizontal mixers uniformly mix pesticide raw materials, ensuring product quality meets industry standards and ensuring consistent quality and production efficiency. This equipment can accommodate a variety of material forms, including powders, granules, solids, liquids, and viscous materials. This equipment meets the complex raw material combinations required in pesticide production and ensures uniform composition of the final product.

Related news

- Horizontal ribbon mixer manufacturer

- Horizontal Ribbon Blender Price

- Stainless steel animal feed horizontal ribbon mixer for feed additives

- 1000L stainless steel ribbon mixer for milk powder raw materials

- PVC Plastic High Speed Mixer

- Ribbon dry mortar mixer

- 1000L stainless steel ribbon mixer

- 1000L stainless steel ribbon mixer for milk powder raw materials