Horizontal ribbon mixer manufacturer

Saturday January-31 2026 16:18:01

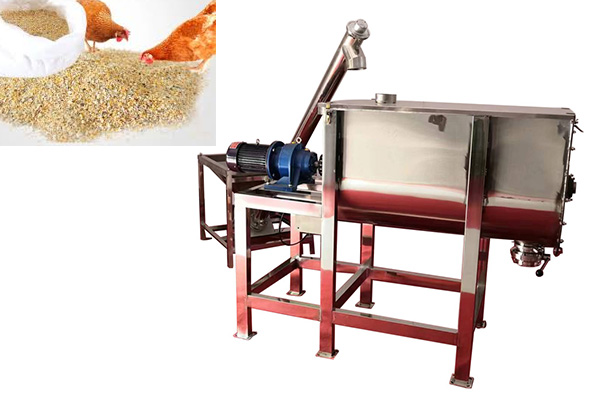

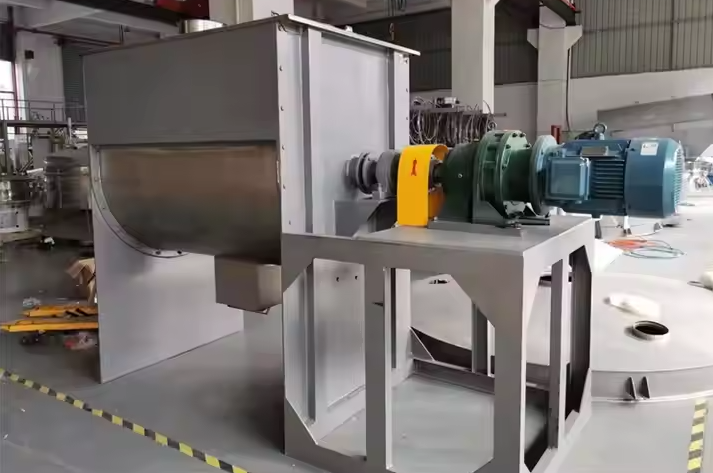

When choosing a horizontal ribbon mixer manufacturer, different manufacturers offer varying specifications and materials, but all are used to mix powders, granules, and liquids. Some manufacturers may only produce carbon steel or stainless steel models, and the mixing capacity for each unit may vary, ranging from 100 kg, 500 kg, or 1000 kg. Therefore, it's crucial to choose a manufacturer that can provide customized products. Our horizontal ribbon mixers are available in stainless steel and carbon steel only. Other materials can be customized based on user needs, with single-batch mixing capacities ranging from 50 kg to 6000 kg. In addition to standard horizontal ribbon mixers, we also offer custom designs for different materials, such as liquid spray, heating, water-cooled jacketed, and corrosion-resistant models.

How to choose a model based on the Horizontal ribbon mixer manufacturer?

To select the appropriate horizontal ribbon mixer model based on a manufacturer, we first need to determine the properties of the material being mixed (powder, granules, liquid, or paste, temperature requirements, and viscosity). This directly determines the equipment material. The required mixing volume per cycle (kg/time) is key to selecting the equipment capacity and size. Furthermore, different machine models and mixing devices are often required for different types of materials.

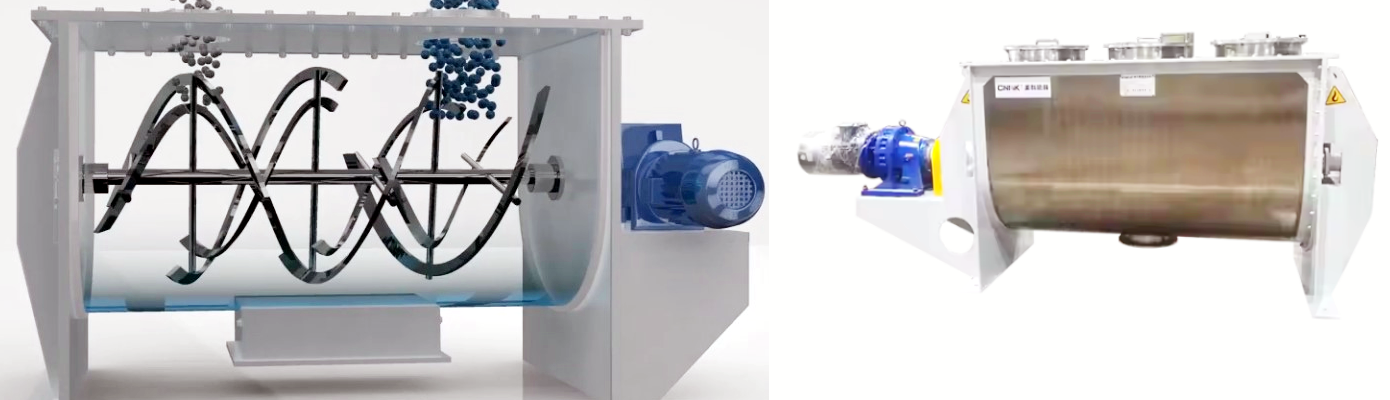

Standard horizontal ribbon mixer adopts a double ribbon (inner and outer ribbon) structure. The inner ribbon transports the material from both ends to the center, and the outer ribbon diffuses the material from the center to both ends to form a convection mixing to ensure that the material mixing uniformity is ≥99%. It is mainly suitable for the mixing of dry powder and granular materials (such as cement, feed, plastic particles). The processing capacity ranges from 50L to 10000L, and the model can be customized according to the production capacity requirements.

Heating/cooling horizontal ribbon mixer: A heating or cooling jacket is installed outside the barrel, which is suitable for materials that require temperature control, such as hot melt adhesives, food additives, etc. There are various forms of electric heating and thermal oil heating. Some materials require precise temperature control during the mixing process. We provide jacket heating or cooling functions, which can heat or cool the materials through media such as thermal oil, steam, cooling water, etc. to ensure the mixing effect and product quality.

Liquid-spraying horizontal ribbon mixer: equipped with a spraying system, quantitative liquid can be added simultaneously during the powder mixing process, which is suitable for processes such as adding oil, water, and flavors. When liquid or viscous materials need to be added to the powder for mixing, our liquid-spraying mixer is equipped with a precise nozzle system that can evenly spray the liquid into the powder to achieve fast and uniform liquid-solid mixing.

Corrosion-resistant horizontal ribbon mixers: Material-contacting parts are lined with 304/316L stainless steel, titanium alloy, or polytetrafluoroethylene (PTFE), providing resistance to acid and alkali corrosion and preventing material contamination. These mixers are widely used in industries requiring high corrosion resistance, such as chemical raw materials (such as dyes and additives), food additives, and pharmaceutical intermediates. Surface treatments such as mirror polishing are also available.

Horizontal ribbon mixer specifications

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

What are the applications of horizontal ribbon mixers?

Typically, horizontal ribbon mixer manufacturers will provide case studies based on user needs. For example, if a user wants to mix cocoa powder, the manufacturer will explain that stainless steel is the ideal material for mixing cocoa powder. (For example, a food factory ordered a stainless steel horizontal ribbon mixer from our factory with a single batch capacity of 50 kg to mix cocoa powder with other ingredients.) This is because stainless steel is not only clean and hygienic for food powders with high hygienic requirements, but also prevents contamination and ensures the quality of the finished product. For general materials, carbon steel is sufficient, offering both cost-effectiveness and durability.

MACHRISE Machinery Manufacturer offers a comprehensive range of Horizontal ribbon mixers. As a professional Horizontal ribbon mixer manufacturer, we can meet the requirements for efficient mixing of powders, granules, and viscous materials with varying production capacity requirements. We achieve uniform dispersion of powders, granules, and liquid additions, with mixing uniformity exceeding 98%. For specialized process requirements, MACHRISE can provide customized twin-ribbon configurations to handle high-viscosity materials or develop single-ribbon configurations for gentle mixing of fragile materials. All mixers are constructed of mirror-polished 304/316 stainless steel and support customized features such as jacket heating and cooling, spray dosing, and PLC control, offering a complete solution from laboratory pilot to large-scale production.