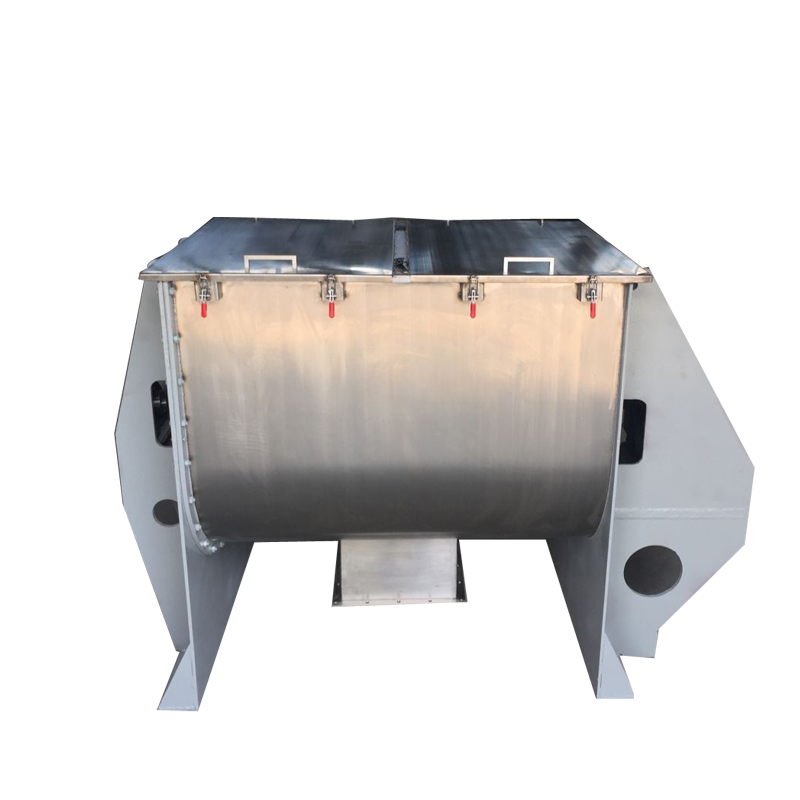

Horizontal ribbon mixer poultry feed

Used to mix and stir various ingredients of poultry feed raw materials, with a mixing uniformity of more than 95%. The price range is: $300.00-$$3,100.00

Mixing capacity per batch: 100-6000公斤

Mixing time: 8-20min

Capacity: up to 1000 liters

Voltage: 380V/220V/450V

What is a Horizontal Ribbon Mixer for Poultry Feed?

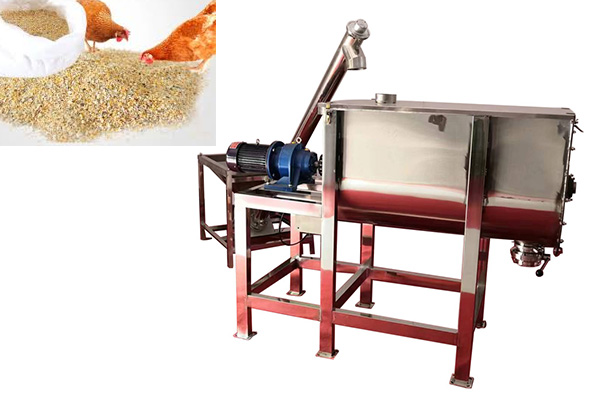

A Horizontal Ribbon Mixer for Poultry Feed is a device used to mix and agitate various poultry feeds. Using a rotating twin-screw ribbon within a horizontal drum, it evenly blends various poultry feed ingredients, including grain meal, soybean meal, premix, minerals, and vitamins, for chicken, duck, and goose feeds, improving the nutritional balance of the feed. Each batch of poultry feed can be mixed in quantities of 50-5000 kg, with a single mixing time of 3-20 minutes, adjustable depending on demand. Mixing uniformity exceeds 95%. The Horizontal Ribbon Mixer for Poultry Feed is commonly used in poultry farms and feed processing plants to mix feed ingredients for chickens, ducks, geese, quail, and other poultry.

What are the advantages of a Horizontal Ribbon Mixer for Poultry Feed?

The Horizontal Ribbon Mixer poultry feed utilizes a double-ribbon design, allowing feed ingredients to fully interpenetrate and shift positions quickly, ensuring highly even distribution of ingredients within the feed, preventing picky eating and malnutrition in poultry. Each batch of materials can be evenly mixed in just 3-10 minutes, improving production efficiency. Whether it's dry powdered grains, granular feed additives, wet feed with a certain amount of moisture, or even high-fiber forage, this horizontal ribbon mixer can easily handle the production of poultry feeds with varying formulations and production processes. Constructed of stainless steel, the mixer ensures clean discharge without residue.

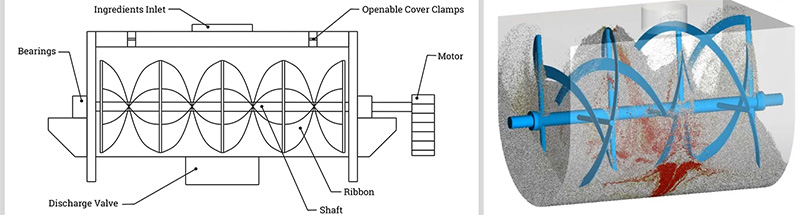

How does the Horizontal Ribbon Mixer poultry feed work?

When the Horizontal Ribbon Mixer Poultry Feed is in operation, various poultry feed ingredients are metered according to a specific ratio and then fed into the U-shaped drum of the horizontal ribbon mixer. The motor drives the transmission components, which in turn drive the ribbon mixing blades to rotate at high speed. The outer ribbon propels the material from the sides of the drum toward the center, while the inner ribbon directs the material from the center to the sides, creating intense convection. While this convection mixing occurs, the material is also sheared and squeezed by the ribbon blades, constantly shifting and intermingling materials at different locations. After multiple cycles, a highly uniform mix is achieved. The evenly mixed feed is discharged through the discharge device for further processing or direct use in poultry feeding.

Horizontal ribbon mixer poultry feed specifications

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

What are the applications of the horizontal ribbon mixer poultry feed?

The horizontal ribbon mixer poultry feed is suitable for mixing various types of powdered, granular, and crumb poultry feeds, such as complete feeds, premixes, and concentrates for broilers, laying hens, ducks, geese, and other poultry. It can also mix functional feeds with added fats and probiotics. It is commonly used in feed processing plants, small and medium-sized poultry farms, family farms, and individual farmers, meeting the needs of various farming scenarios.

How should I choose a horizontal ribbon mixer poultry feed for different types of poultry feed?

Complete feed (suitable for chicken, duck, goose, etc.): Requires mixing multiple components such as grain meal, soybean meal, oil, and minerals. Choose a standard carbon steel ribbon mill. The capacity is determined by daily production demand: 50-500 kg for small operations (such as the SLW-500), and 2000 kg or more for large operations (such as the SLW-3000). Ensure mixing uniformity ≥ 95%, suitable for mass production.

Concentrated feed (high protein): Contains a high proportion of soybean meal and fish meal and is prone to moisture absorption. Choose a stainless steel inner chamber mill (anti-corrosion) with a design that maintains a gap between the ribbon and the housing of ≤3 mm to minimize residue. A capacity of 1000-2000 kg is recommended for optimal efficiency and mixing accuracy.

Premix (vitamin/trace element type): For extremely high uniformity requirements (≥96%), a twin-screw reverse intensive mixer with variable frequency speed regulation (adjustable from 3 to 10 minutes) is required. 304 stainless steel is preferred. A small machine with a capacity of 50-500kg is recommended to avoid cross-contamination of materials and is suitable for small-batch precision mixing.

Horizontal ribbon mixer poultry feed case

| Application Scenarios | Mixing Materials | Mixing Amount | Mixing Time | Selected Models |

| Small Chicken Farms | Corn Flour, Soybean Meal, Premix | 200kg | 5 Minutes | WLH - 200 |

| Medium-sized duck farm | Grain meal, fish meal, oil, vitamins | 500kg | 6 minutes | WLH - 500 |

| Large goose farm | Corn, bran, minerals, probiotics | 1000kg | 8 minutes | WLH - 1000 |

| Small-sized feed processing plant (laying hen feed) | Various grain meal, concentrates, additives | 1500kg | 10 Minutes | WLH - 1500 |

| Family Farm (Quail Farming) | Corn Meal, Soybean Meal, Trace Element Premix | 100kg | 3 Minutes | WLH - 100 |

Frequently Asked Questions about the Horizontal Ribbon Mixer Poultry Feed

Q1: How much feed can a Horizontal Ribbon Mixer Poultry Feed mix per batch?

The mixing capacity varies depending on the model, ranging from 200-500 kg per batch for a small machine to 6,000 kg per batch for a large machine. Larger batches can also be customized to meet your needs.

Q2: How long does it take to mix a batch of feed?

The Horizontal Ribbon Mixer Poultry Feed completes loading, mixing, and unloading in a very short time, with the mixing time typically taking only 3 to 5 minutes, making it very efficient.

Q3: Can it mix feed containing liquids, such as grease?

Yes, if desired, the Horizontal Ribbon Mixer Poultry Feed can be equipped with an optional liquid addition system. This system evenly sprays grease or other liquid additives through pipes and nozzles, with an addition rate of up to 10%-20%.

Q4: Is the equipment difficult to clean? Is there a lot of residue?

Cleanup is easy, with minimal residue. The modern design focuses on low residue. The pneumatically operated wide-opening door and special ribbon design ensure quick and clean unloading, effectively reducing contamination between batches. The open design also facilitates manual cleaning and maintenance.

Q5: How much does a Horizontal Ribbon Mixer Poultry Feed cost?

The price of a Horizontal Ribbon Mixer Poultry Feed ranges from $300.00 to $3,100.00. The specific price depends on the material, mixing volume, model, and configuration. You can contact our online customer service or email sales@machrise.com for a quote based on your needs.