Heavy-Duty Ribbon Blender Ceramic Powder And Glaze Mixing

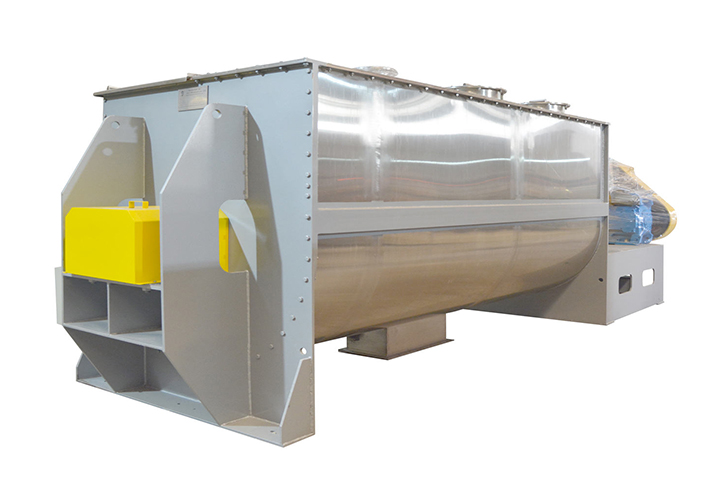

The heavy-duty ribbon blender ceramic powder and glaze mixing is a large-scale mixing and stirring equipment specifically designed for ceramic production. It's used not only in ceramic production but also in the building materials and chemical industries. Capacity: 10,000L Voltage: 220-660V Power: 55kW Material: SUS304, SUS304L, SUS316, SUS316L

What is a heavy-duty ribbon blender ceramic powder and glaze mixing?

The heavy-duty ribbon blender ceramic powder and glaze mixing features an internal and external speed differential mixing system. Its wear-resistant materials and anti-stick treatment achieve forced convection, shear, and dispersive mixing of the materials. This ensures consistent particle size and composition distribution after mixing, effectively solving the problem of mixing ceramic powders and glazes. It also supports continuous and batch production, reduces labor costs through automated parameter control, stabilizes mixing quality, and improves the efficiency and stability of ceramic production.

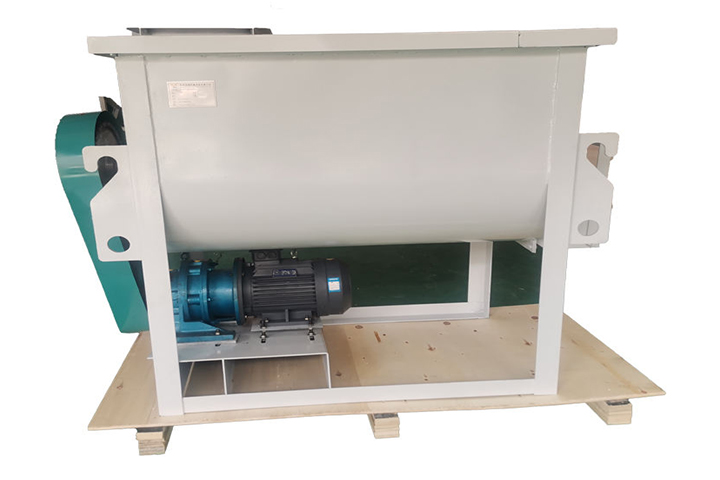

How does a heavy-duty ribbon blender ceramic powder and glaze mixing work?

The heavy-duty ribbon blender ceramic powder and glaze mixing operates by creating continuous axial convection circulation within the cylinder through the differential rotation of inner and outer ribbons, breaking down the stratified state of the material when it is stationary. The shearing and tumbling of the material by the ribbons allows for full contact between the different components, ensuring uniform particle size and composition distribution after mixing. The entire process utilizes a sealed container and controllable speed, adapting to the high density and viscosity of ceramic materials. This minimizes material residue and equipment wear, ensuring efficient and high-quality mixing.

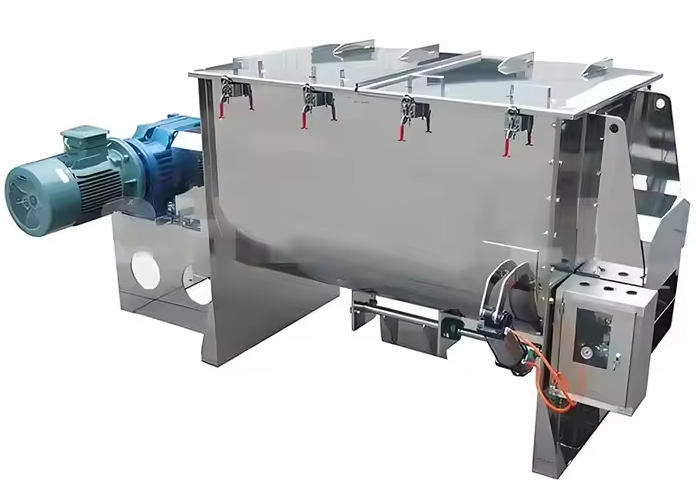

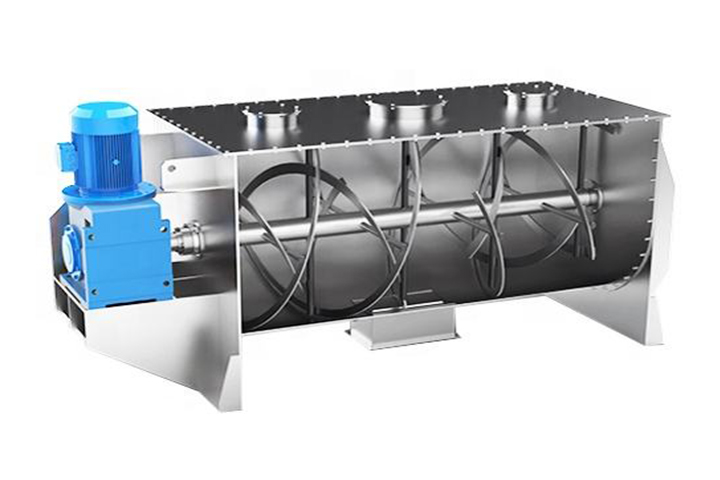

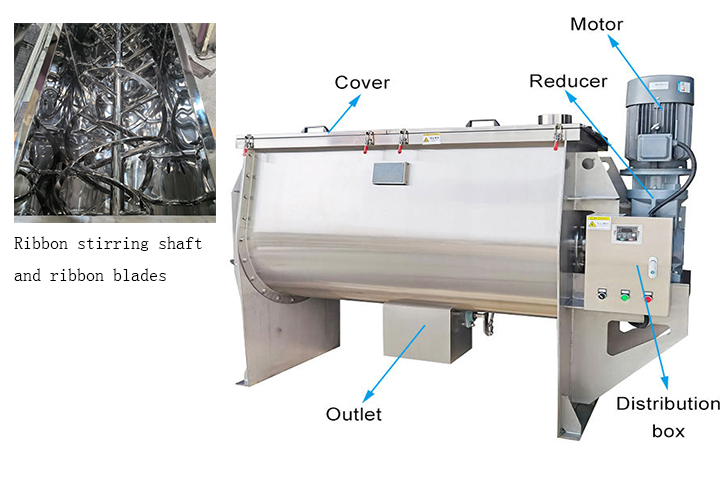

What is the structure of the heavy-duty ribbon blender ceramic powder and glaze mixing?

Container: The cylinder is constructed of thickened steel plates or a wear-resistant alloy welded together in a U-shaped structure.

Inlet and outlet ports: Located at the upper and lower ends of the container.

Ribbon agitator shaft:Made of high-strength alloy steel, it extends through the cylinder.

Ribbon Blades: The outer ribbon spirals along the inner wall of the cylinder. The inner ribbon is located near the shaft and spirals in the opposite direction to the outer ribbon. A middle ribbon (some have one) enhances radial shear and dispersion.

Motor: Provides power.

Reducer:Converts motor speed into the low-speed, high-torque output required by the ribbon.

Frame: Supports the entire equipment.

What are the material characteristics of a heavy-duty ribbon blender ceramic powder and glaze mixing?

Ceramic powders:Mostly high-hardness inorganic powders with high density and prone to agglomeration. They tend to fly when dry and stick to the wall when wet.

Glazes:Mostly slurries or powders containing a glassy phase and exhibit a certain degree of stickiness.

High mixing uniformity requirements:Must exceed 95%, with high-precision ceramics requiring over 98%.

Susceptible to wear: Ceramic powders are high in hardness and can wear the inner wall of the container and the ribbon during mixing.

Susceptible to adhesion:Glazes tend to adhere to the ribbon and the inner wall of the container.

What are the parameters of a heavy-duty ribbon blender ceramic powder and glaze mixing?

Capacity:Common sizes include 0.25m³, 0.5m³, and 1m³ (corresponding to mixing capacities of 100-150kg, 200-300kg, and 400-600kg), with larger sizes reaching up to 10m³ (4,000-6,000kg).

Power:3-3.5kW for a 0.25m³, 7.5-15kW for a 1m³, and 45-75kW for a 10m³.

Speed:Generally 10-30 rpm.

Mixing time:20-30 minutes (for mixing ceramic powder and glaze).

Weight:Approximately 500kg for a 0.25m³ and 8,900kg for a 10m³.

What are the characteristics of a heavy-duty ribbon blender ceramic powder and glaze mixing?

Material:Key components are coated with wear-resistant alloy or ceramic for high hardness and wear resistance, extending equipment life. The ribbon surface and the inner wall of the barrel are Teflon-coated or mirror-polished to reduce material adhesion.

Mixing Capacity:The differential rotation of the inner and outer ribbons creates a complex motion of axial pushing, radial diffusion, and vertical flipping, effectively breaking up powder agglomerates. Mixing uniformity can reach over 95%.

Precise Control:Equipped with a PLC control system, mixing parameters can be preset to ensure consistent mixing conditions for different batches of materials. The fully sealed design prevents impurities from entering, and inert gas can be used when necessary to prevent oxidation during mixing.

What are the applications of heavy-duty ribbon blender ceramic powder and glaze mixing?

The advantages of heavy-duty ribbon blender ceramic powder and glaze mixing lie in their adaptability to materials with high viscosity and hardness, meeting the needs of industrial mass production.

Ceramic Production:They can be used in the production of household ceramics, artistic ceramics, architectural ceramics, sanitary ceramics, structural ceramics, functional ceramics, and ceramic pigments, resolving the problem of difficult mixing of ceramic powders and glazes. They provide quality assurance throughout the ceramic production process and are an indispensable key piece of equipment in ceramic chemical production.

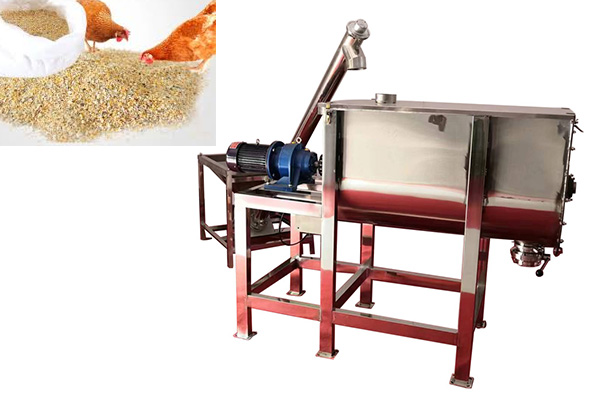

Other fields:chemical industry, building materials and mining industry, food and pharmaceutical industry, metallurgical industry, feed and agricultural industry, etc.

Related news

- Horizontal ribbon mixer manufacturer

- Horizontal Ribbon Blender Price

- Stainless steel animal feed horizontal ribbon mixer for feed additives

- 1000L stainless steel ribbon mixer for milk powder raw materials

- Pesticide Horizontal Mixer

- PVC Plastic High Speed Mixer

- Ribbon dry mortar mixer

- 1000L stainless steel ribbon mixer