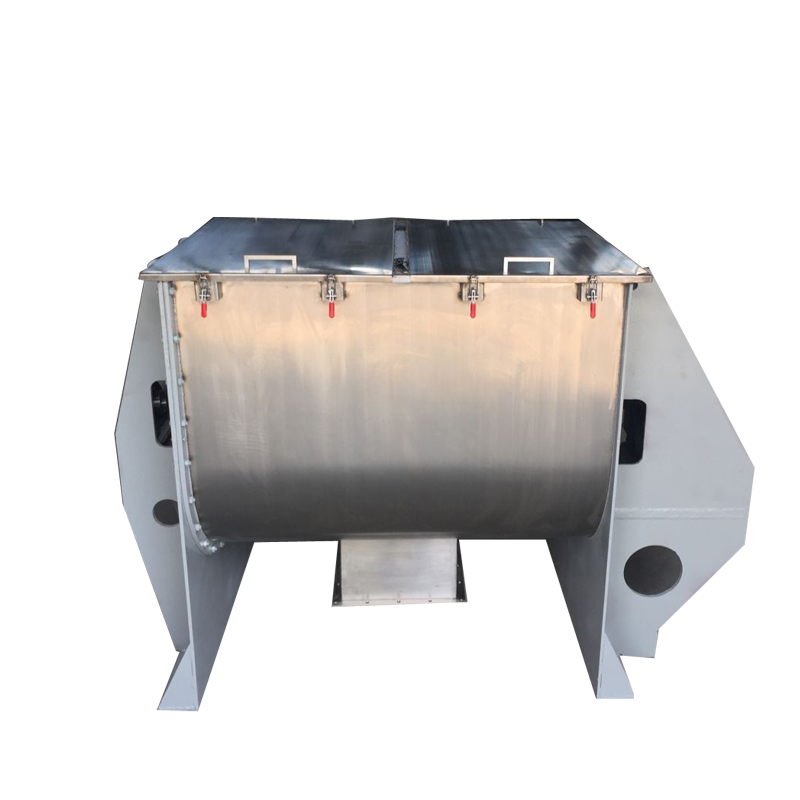

Stainless steel animal feed horizontal ribbon mixer for feed additives

Thursday October-16 2025 11:49:39

The feed equipment manufacturing company has launched a new stainless steel animal feed horizontal ribbon mixer for feed additives, aiming to provide efficient, hygienic and precise mixing solutions for the feed processing industry. Stainless steel animal feed horizontal ribbon mixer for feed additives adopts advanced mixing structure and food-grade stainless steel material, and is designed for uniform mixing of trace feed additives and main materials. It can significantly improve the mixing uniformity, ensure accurate feed nutrient ratio, and meet the dual requirements of modern feed companies for quality and efficiency.

Its horizontal U-shaped barrel structure with inner and outer double-layer spiral ribbon stirring blades can complete the efficient mixing of vitamins, minerals, enzyme preparations and other additives in a short time, and the CV value can be controlled within 5% to ensure the consistency of each batch of products.

Applicable materials

Stainless steel animal feed horizontal ribbon mixer for feed additives is particularly suitable for the uniform mixing of powdered and granular feed additives with the main ingredients, such as:

Trace elements, enzyme preparations, antioxidants, vitamins, etc. in premixes;

Nutritional additives, growth promoters, etc. in livestock and poultry and aquatic feed;

Farms, small feed mills, additive batching workshops, etc.

Structural composition and working principle

Stainless steel animal feed horizontal ribbon mixer for feed additives is a mixing equipment specially used for mixing feed additives with basic feed raw materials (such as corn flour, soybean meal, wheat bran, etc.). It adopts a horizontal barrel structure and double-layer spiral ribbon blades. It is made of stainless steel and has a certain volume (such as 500L, 1000L, etc.). It can be equipped with an upper cover, a feed port, and an observation port.

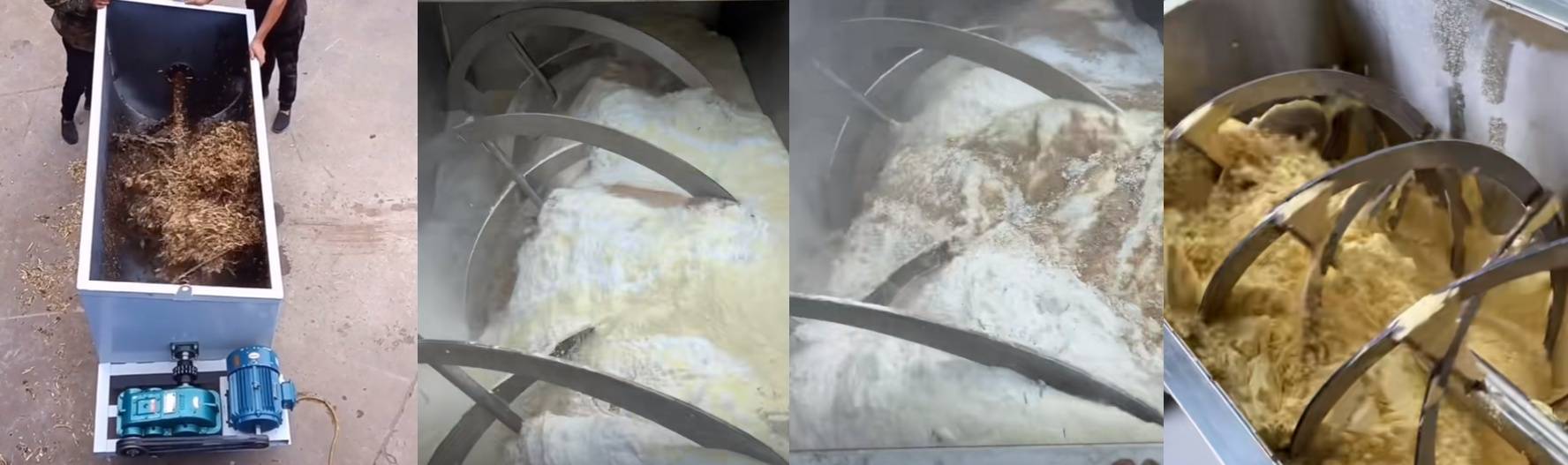

The motor drives the main shaft of the spiral ribbon to rotate through the reducer. The outer spiral strip moves the material to the center position, and the inner spiral strip pushes the material to a certain position or end plate. The two make the material diffuse, convect, shear, dislocate and radially move, so as to achieve a uniform mixing effect in a short time.

What are the advantages of stainless steel animal feed horizontal ribbon mixer for feed additives?

There are many kinds of feed additives. If they are not mixed evenly, it will lead to unbalanced nutrition of animals. Some additives are easy to agglomerate in a humid environment.

Stainless steel animal feed horizontal ribbon mixer for feed additives is usually equipped with double or multi-layer spiral ribbons. The inner and outer spiral ribbons rotate in different directions or speeds to form a convection cycle. This design allows the material to be mixed in all directions and dimensions in the mixing drum. Even trace amounts of additives can be evenly dispersed into a large amount of basic feed, thereby greatly improving the mixing uniformity. Its forced mixing effect can also effectively break potential agglomerations and avoid dead corners.

Different types and batches of additives often need to be mixed in feed production. If the mixer is not cleaned thoroughly, it is easy to cause the residues of the previous batch to contaminate the next batch, affecting product quality and safety.

The parts of the equipment that come into contact with the material are all made of stainless steel. The surface is smooth and non-porous, which is not easy to absorb the material and reduces the residue. Some are also designed with quick disassembly or cleaning ports, which effectively eliminate the risk of cross contamination.

Technical parameters of stainless steel animal feed horizontal ribbon mixer for feed additives

|

Model (LRB series) |

total volume (L) |

effective volume (L) |

production capacity (kg/batch) |

motor power (kW) |

mixing time (min) |

discharging method |

|

LRB-100 |

100 |

70 |

40–60 |

1.5 |

5–10 |

manual butterfly valve |

|

LRB-300 |

300 |

210 |

150–200 |

3 |

5–10 |

manual butterfly valve |

|

LRB-500 |

500 |

350 |

250–350 |

4 |

5–10 |

manual or pneumatic valve |

|

LRB-1000 |

1000 |

700 |

500–700 |

5.5 |

5–8 |

Pneumatic valve |

|

LRB-1500 |

1500 |

1050 |

750–1100 |

7.5 |

5–8 |

Pneumatic valve |

|

LRB-2000 |

2000 |

1400 |

1000–1400 |

11 |

5–8 |

Pneumatic valve |

|

LRB-3000 |

3000 |

2100 |

1500–2100 |

15 |

5–8 |

Pneumatic valve |

What can the stainless steel animal feed horizontal ribbon mixer for feed additives be used for?

Stainless steel animal feed horizontal ribbon mixer for feed additives is mainly used in the feed production links of livestock, poultry, aquatic products, ruminants, etc., to evenly mix trace or small amounts of feed additives (such as vitamins, enzyme preparations, mineral elements, growth promoters, etc.) with basic feed raw materials (such as corn flour, soybean meal, wheat bran, etc.).

Premix production workshop

Mixing before packaging of feed additive enterprises

Self-mixed feed system of farms

Aquatic feed mixing line

Veterinary drug additive feed processing plant

In the process of feed processing, feed additives (such as vitamins, minerals, enzyme preparations, antibiotics, trace elements, etc.) are small in addition, complex in composition, different in particle size, easy to stratify, easy to adsorb, etc. Stainless steel animal feed horizontal ribbon mixer effectively solves many common technical problems in the process of mixing feed additives through its efficient convection mixing structure, food-grade hygienic design, good adaptability and configurability, and is suitable for refined feed production needs.