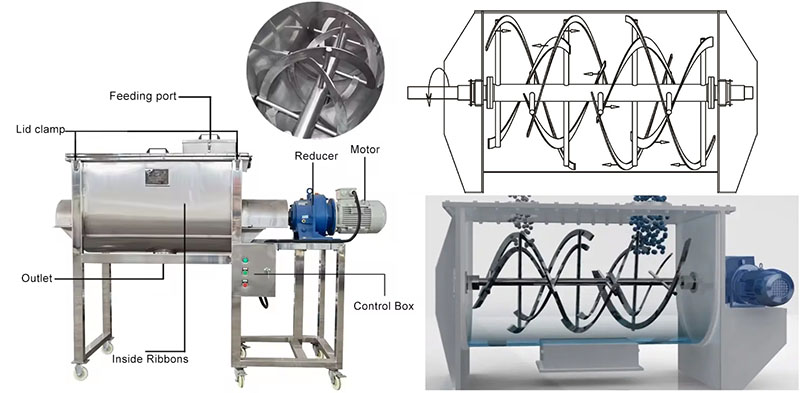

Horizontal dry powder mixer

The stirring device allows for uniform mixing of dry powder materials of varying composition and proportions, breaking up dry powder lumps and improving mixing uniformity. The price ranges from $300 to $3,500.

Mixing capacity: 100-6000kg

Mixing time: 8-20min

Capacity: 100-5000L

Weight: 100kg-7500kg

Voltage: 380 V

What is a Horizontal Dry Powder Mixer?

A horizontal dry powder mixer features a horizontal cylindrical structure. It uses a rotating ribbon or paddle to mix various types of dry powders in a relatively short time, breaking up lumps and eliminating stratification, ensuring a consistent mixture. It can be used for mixing various dry powders, including putty powder, dry mortar, flour, additives, powdered raw materials, pigment mixing for the chemical industry, dry powder feed for the feed industry, cement, gypsum powder, talcum powder, mosquito repellent powder, and other dry powders, as well as small amounts of additives.

Horizontal dry powder mixers have capacities ranging from 50L to 5000L, and mixing times generally range from 3 to 15 minutes, depending on the material characteristics and mixing requirements. Horizontal dry powder mixers are available in stainless steel (corrosion-resistant, suitable for food/chemical dry powders) and carbon steel (low-cost, suitable for general dry powders).

What types of horizontal dry powder mixers are there?

Horizontal dry powder mixers are divided into U-type and O-type according to the structure, depending on the materials being mixed and the application scenarios. They can be divided into small, medium and large types according to the powder capacity. They can also be customized according to needs, such as heating type, cooling type, corrosion-resistant type, etc.

| Classification | Type | Features | Applicable Scenarios |

| Structural Design | U-Type Mixer | Fully Circular Material Tumbling, High Loading Factor, Small Footprint | Limited Space Working Environment, High Mixing Uniformity Requirements |

| O-type mixer | Excellent sealing performance, reducing bottom gaps to 1-2 mm, and minimizing dead zones for materials | Higher requirements for sealing performance and minimizing dead zones for materials | |

| By capacity | Small (0-500L) | Low power consumption, small footprint, and flexible operation | For laboratories, small batch production, and new product development |

| Medium (500-2000L) | Balanced production capacity and flexibility, offering high cost-effectiveness | Production lines for small and medium-sized enterprises | |

| Large (2000L and above) | Large-scale production, high degree of automation | Large-scale production enterprises, continuous large-scale production | |

| By functional characteristics | General type | Basic mixing function, meeting general dry powder mixing needs | General dry powder material mixing |

| Heating type | Equipped with a heating jacket, capable of heating and drying | Processes requiring heating and drying | |

| Refrigeration type | Equipped with a cooling system, capable of mixing at a reduced temperature | Mixing of temperature-sensitive materials | |

| Corrosion-resistant type | Using special stainless steel | Acidic and alkaline materials, pharmaceutical raw materials, etc. |

What are the advantages of a Horizontal dry powder mixer?

The Horizontal dry powder mixer offers fast mixing speeds, typically completing a batch in 6-8 minutes. It also features a timer for precise control of mixing time. Its ribbon design and mixing principle ensure over 99% uniformity, with zero dead zones and residue. It is suitable for handling dry powders of varying specific gravities and particle sizes, including coarse, fine, and ultrafine powders. The wide-opening discharge port allows for quick, all-in-one discharge, avoiding carryover and cross-contamination, while also preventing material segregation caused by over-mixing.

What are the applications of a Horizontal dry powder mixer?

The Horizontal dry powder mixer is used in the building materials, chemical, food, pharmaceutical, and feed industries to mix various types of dry powders, including lightweight, easily airborne, fibrous, corrosive, and ultrafine powders. Building material dry powders: interior and exterior wall insulation mortar, crack-resistant mortar, plastering mortar, bonding mortar, self-leveling mortar, filler mortar, putty powder, tile adhesive, waterproofing materials, etc.

Chemical dry powders: dyes, pigments, resin powder, plastic powder, rubber additives, detergents, fertilizers, pesticides, insecticides, etc.

Food dry powders: seasonings, additives, vitamins, milk powder, salt, starch, food additives, etc.

Pharmaceutical dry powders: Traditional Chinese medicine powders, Western medicine raw materials, health supplement raw materials, capsule granules, etc.

Feed dry powders: fish feed, poultry feed, animal feed, bird feed, feed additives, etc.

Other specialty dry powders: ceramic powder, refractory materials, mining powder, metal powder, fireworks raw materials, etc.

How does a horizontal dry powder mixer work?

When the Horizontal Dry Powder Mixer is in operation, dry powder enters the horizontal drum through the feed port and is evenly spread across the drum bottom under the action of gravity. A motor, via a reducer, drives the twin helical blades or paddles inside the drum, pushing the powder toward the center and generating shear force to break up lumps. Partially counter-rotating helical blades create bidirectional convection, accelerating powder penetration. The paddles also scrape away residual material from the drum wall to prevent uneven distribution. Once the powder achieves a three-dimensional motion through "pushing, convection, and shearing" and a uniformity of over 95%, mixing is stopped for the set duration and the material is discharged through a valve.

Horizontal Dry Powder Mixer Specifications

| Parameter Model | 500 Model | 1000 Model | 1500 Model | 2000 Model | 3000 Model |

| Capacity | 0.5 Ton | 1 Ton | 1.5 Ton | 2 Ton | 3 tons |

| Mixing time | 6-8 minutes | 6-8 minutes | 6-8 minutes | 8-10 minutes | |

| Power | 5.5 kW | 7.5 kW | 11 kW | 15 kW | 22 kW |

| Speed | 480 rpm | 480 rpm | 480 rpm | 480 rpm | 360 rpm |

| Equipment Height | 2.3m | 2.7m | 2.9m | 3.2m | 3.5m |

| Weight | 200kg | 300kg | 350kg | 400kg | 600kg |

| Floor Area | 1 square meter | 2 square meters | 2.2 square meters | 2.2 square meters | 2.5 square meters |

Horizontal dry powder mixer customer case

| Application Scenario | Mixed Material | Single Batch Mixing Volume | Single Batch Mixing Time |

| Small Dry Mortar Production Plant (Building Materials) | Cement, Quartz Sand, Fly Ash, Hydroxypropyl Methylcellulose | 2m³ | 3-5 minutes |

| Medium-sized pigment additive processing plant (chemical industry) | Titanium dioxide, calcium carbonate, dispersant, stabilizer | 5m³ | 5-8 minutes |

| Large-scale livestock and poultry dry powder feed plant (feed) | Corn flour, soybean meal, premix, vitamins | 15m³ | 8-10 minutes |

| Medium-sized water-based dry powder paint plant (paint) | Heavy calcium powder, talc, emulsion powder, defoaming agent | 8m³ | 6-8 minutes |

Frequently Asked Questions about Horizontal Dry Powder Mixers

Q: How long does a horizontal dry powder mixer take to mix each batch of materials?

A: Typically, each batch takes 6-10 minutes, depending on the material characteristics and the required uniformity.

Q: Which is better, a horizontal or vertical dry powder mixer?

A: Each has its own advantages, and the choice depends on the material properties and the application scenario. Horizontal mixers are more suitable for handling extremely light, large-particle, fibrous, and moisture-sensitive materials, and are more durable. Vertical mixers are primarily used for smaller, dry, and non-abrasive materials. They are generally less expensive but offer lower abrasion resistance.

Q: Can a horizontal dry powder mixer mix dry powder with liquid?

A: Yes. Horizontal dry powder mixers can incorporate a certain percentage of liquid into the mix, up to 10%.