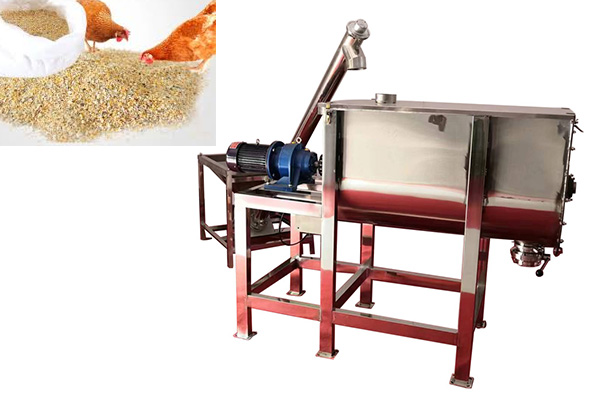

Horizontal Ribbon Blender Price

Saturday January-31 2026 16:18:55

Horizontal Ribbon Blender Price: $500-$7500. The specific price depends primarily on the model, material, capacity, and features. Prices vary depending on the capacity of the blender. A 50kg household blender costs significantly less than a 1000kg industrial blender. This is because larger blenders require a more robust structure, a more powerful drive, and more sophisticated craftsmanship.

Horizontal ribbon mixers have a wide price range, depending on the material, model, and mixing method, as well as the mixing volume, material, and configuration. Small units made of conventional carbon steel (e.g., 100-500 liters) cost approximately $200-$5,000, while those made of food- or pharmaceutical-grade stainless steel (e.g., 1,000-2,000 liters) range from $8,000-$20,000. Capacity should be determined based on production output. The key to selecting a model is matching the material characteristics. For dry granules or powders, a standard U-shaped barrel and ribbon mixer are sufficient. For viscous or heat-sensitive materials, a stainless steel model with jacketed heating and cooling is recommended. For materials requiring solid-liquid mixing or prone to dust generation, a model equipped with a liquid spray system or vacuum function should be selected.

Horizontal Ribbon Blender Price Table (for reference)

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 | |

| Price | $500-$1200 | $1000-$2200 | $1500-$3000 | $1800-$3500 | $2100-$4200 | $2500-$4900 | $3000-$5200 | $3500-$5900 | $4000-$6200 | $4500-$7000 |

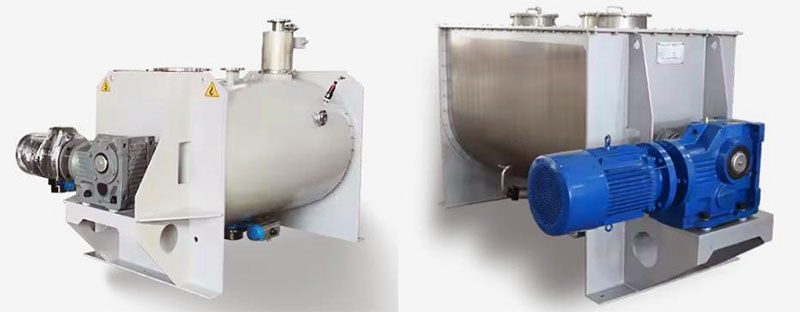

How do materials affect Horizontal Ribbon Blender Price?

Horizontal Ribbon Blender Price varies depending on the material, as different materials differ in corrosion resistance, wear resistance, and processing difficulty. Carbon steel Horizontal Ribbon Blenders are cheaper and are generally used to mix non-food grade, non-corrosive materials. Since carbon steel has poor corrosion resistance and is prone to rust, it is generally surface treated, such as painting and galvanizing, to improve its corrosion resistance, but this also increases costs. Stainless steel (304 stainless steel and 316L stainless steel) has good corrosion resistance and wear resistance and can be used in work environments with high hygiene requirements or strong corrosiveness. The price is also about 30%-50% higher than 304 stainless steel. Moreover, 316L stainless steel has molybdenum added to it, making it more resistant to corrosion and acid and alkali than 304 stainless steel.

| Capacity (L) | Processing capacity (kg) | Price range |

| 50–100 L | 20–50 kg | $300 – $1,000 |

| 200–300 L | 100–150 kg | $1,000 – $1,300 |

| 500 L | 200–300 kg | $1,000 – $3,200 |

| 1000 L | 400–600 kg | $3,500 – $4,000 |

| 1500 L | 600–900 kg | $4,200 – $5,500 |

| 2000 L | 900–1200 kg | $6,800 – $7,500 |

| 3000 L | 1200–1800 kg | $9,000 – $10,000 |

| 5000 L | 2000–3000 kg | $10,000 – $12,000 |

How does customization affect the Horizontal Ribbon Blender price?

In terms of customization, Horizontal Ribbon Blender Price is also different. When the ordinary Horizontal Ribbon Blender cannot meet the needs, it is necessary to customize the relevant product configuration, including heating/cooling jackets, liquid spray systems, vacuum structures, crushing blades and other components. For example, the basic mixer only has simple material mixing functions and is relatively cheap. However, special features such as heating, which allows the introduction of thermal oil or steam into the jacket to raise the material temperature for hot-melt mixing, cooling, which allows the introduction of cooling water into the jacket to control the material temperature, and explosion-proof features, such as explosion-proof motors and electronic control systems, for mixing flammable and explosive materials, can be added. Each additional feature increases the cost by $100-$800. A blender with heating can cost $500-$1,000 more than a standard blender, while explosion-proof blenders can cost several times more, reaching over $10,000.

When choosing a Horizontal Ribbon Blender, price is not the only factor to consider. You should also consider the material properties (powder, granules, viscosity, moisture content) to be mixed, the equipment capacity and size, the mixing volume per batch (kg/hour), and the configuration. Only then can you choose the right equipment. The single mixing volume is 50-5000 kg, and the equipment capacity is 10L, 100L, 200L, 500L, 1000L, etc., which can be customized according to your needs.