Crushing and Mixing Machine Fertilizer Production

A crushing and mixing machine fertilizer production is a key piece of equipment in the fertilizer processing process. Its core function is to transform raw materials into uniform, qualified semi-finished or finished fertilizer products through both pulverizing and mixing. Agitator speed:10-50 rpm. Pulverizer speed:1000-3000 rpm. Processing capacity:0.5-5 t/h for small units, 10-50 t/h for large units.

What is a crushing and mixing machine fertilizer production?

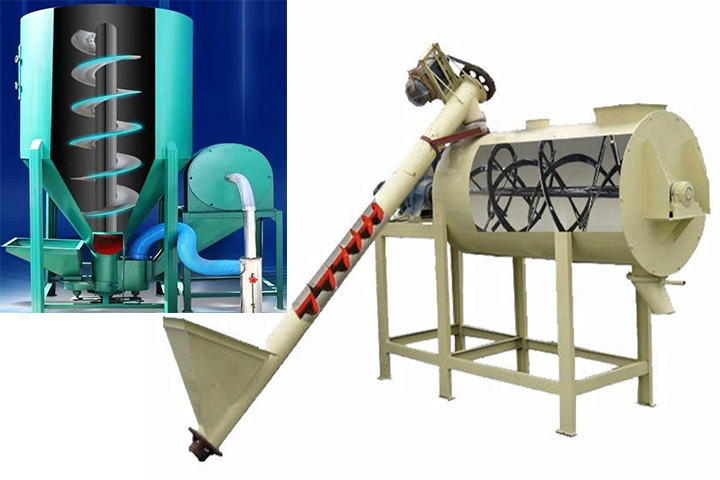

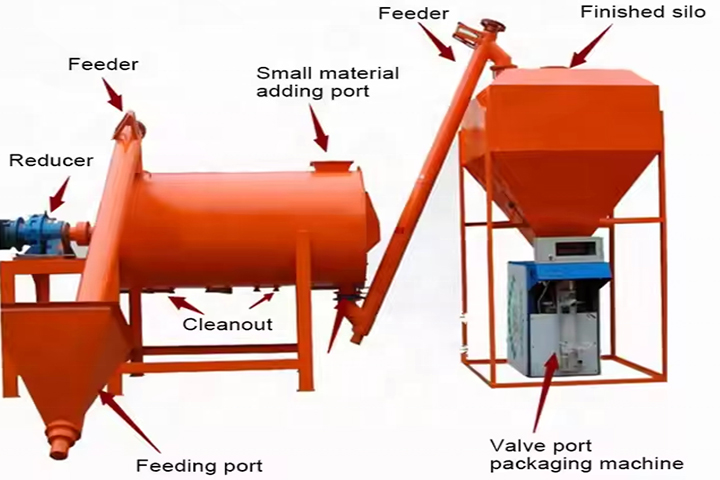

A crushing and mixing machine fertilizer production utilizes an integrated pulverizing and mixing design to pulverize and uniformly mix the raw materials required for fertilizer production. This completes the entire process from initial raw material processing to mixing in one operation, streamlining the fertilizer production line, improving production efficiency, and shortening production cycles. This ensures that qualified raw materials are produced for subsequent fertilizer processing.

How does a crushing and mixing machine fertilizer production work?

A crushing and mixing machine fertilizer production uses a pulverizing element to pulverize lumpy, fibrous, or large-particle raw materials to the desired particle size. At the same time, the crushed raw materials enter the mixing bin. The crushing and mixing machine fertilizer production uses a stirring mechanism to thoroughly mix the various raw materials, ensuring uniform distribution of the materials, ensuring the quality of the fertilizer, and ensuring the stability of the nutrients in the fertilizer. Improving the quality and application efficiency of the final fertilizer product is a key device for ensuring quality and efficiency in industrial fertilizer production.

What is the crushing and mixing machine fertilizer production?

Feeding device:Feed hopper, conveyor device

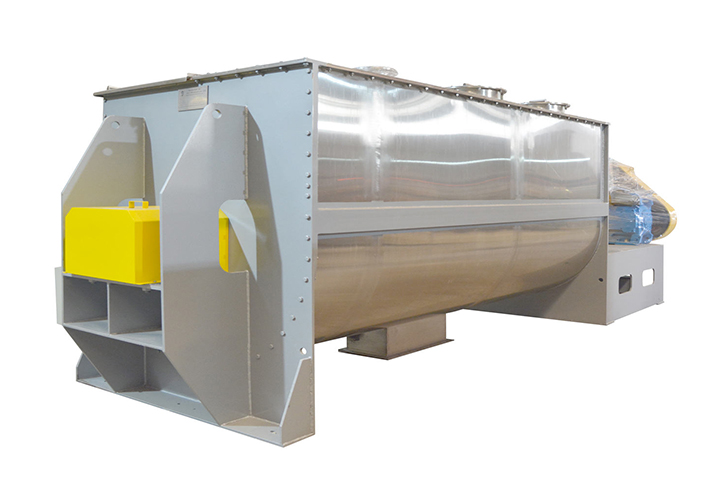

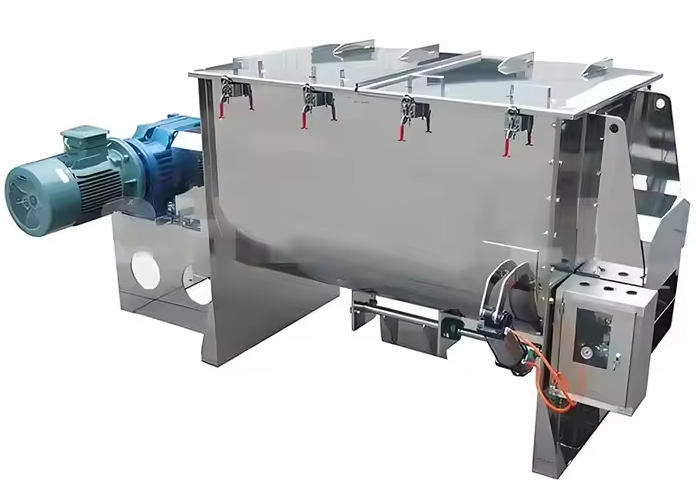

Grinding device:Grinding chamber, grinding cutters or components, screen

Mixing device:Mixing chamber, stirring components, guide plate

Power unit:Motor, transmission equipment

What are the characteristics of a crushing and mixing machine fertilizer production?

Integrated design:Combining grinding and mixing into one machine, the grinder-mixer can complete the process from coarse to uniformly mixed materials in one device, reducing production steps and improving overall fertilizer production efficiency.

High adaptability:The high-speed shearing action of the grinding element in the fertilizer production grinder-mixer can adapt to the grinding requirements of a variety of fertilizer raw materials.

Adjustable Parameters:The degree of material pulverization can be controlled by replacing screens (of varying apertures) or adjusting the speed of the pulverizing element.

Durable Material:Parts contacting the material are made of corrosion-resistant materials.

Suitable for Modular Production:Large continuous units can be connected to automatic loading and conveying systems to achieve large-scale continuous production.

What are the parameters of a crushing and mixing machine fertilizer production?

Power:5.5-75kW for the pulverizing section, 3-30kW for the mixing section. This varies depending on the equipment specifications.

Pulverizing Methods:Hammer (for medium- and low-hardness materials), Claw (for fibrous organic fertilizers), Impactor (for impactor-type materials).

Pulverization Degree:Typically 20-60 mesh.

Mixing Methods:Ribbon (horizontal, for high mixing uniformity), Paddle (for sticky materials), Drum (for impactor-type materials).

Mixing Time:2-10 minutes for a loading rate of 60%-80%.

What are the applications of crushing and mixing machine fertilizer production?

The crushing and mixing machine fertilizer production directly impact the fertilizer's nutrient uniformity and application effectiveness. It is a key piece of equipment for achieving large-scale, standardized fertilizer production and is widely applicable to the processing of various fertilizer types, including compound fertilizers, organic fertilizers, organic-inorganic compound fertilizers, and water-soluble fertilizers (pre-treatment of solid raw materials).

Grinding:Solid raw materials used in fertilizer production are crushed into fine particles through grinding, reducing variations in hardness and particle size, paving the way for subsequent mixing, reactions, or granulation. For some inorganic raw materials with low solubility, grinding increases the contact area between the material and the solvent, accelerating dissolution and improving subsequent dissolution or reaction efficiency, thereby ensuring nutrient uniformity.

Mixing:In the production of compound and formulated fertilizers, grinder/mixers use stirring and shearing to uniformly mix trace elements with elemental fertilizers in specific proportions, preventing the occurrence of excessive or insufficient nutrient concentrations in certain areas of the fertilizer.

Related news

- Fully Automatic Vertical Molding Soft Candy Packaging Machine Introduction

- Tablet and powder packaging machine

- Standard Side-Sealing Packaging Machine

- Fully Automatic Vertical Molding Soft Candy Packaging Machine

- Heavy-Duty Ribbon Blender Ceramic Powder And Glaze Mixing

- Pesticide Horizontal Mixer

- PVC Plastic High Speed Mixer

- Ribbon dry mortar mixer