Multi-material vacuum weighing system

Multi-material vacuum weighing system is an advanced industrial weighing and conveying solution that can accurately weigh and batch a variety of powders, granules or other bulk materials under vacuum or inert atmosphere.

Weight (KG): 260/customizable

Conveying distance: up to 30 meters

Explosion-proof function: optional

Filter material: SUS304/SUS316

Air consumption: 10-20 liters

Hose material: SUS304/SUS316/plastic

Unloading time: adjustable

PLC control cabinet: optional

Applicable industries: manufacturing plants, food and beverage plants, energy and mining.

What is a Multi-material vacuum weighing system?

Multi-material vacuum weighing system is an automated equipment upgraded on the basis of single-material vacuum weighing technology. Through multi-channel weighing modules and intelligent sub-control systems, it can achieve synchronous metering and proportioning of 2-8 different materials, which is suitable for production scenarios that require precise mixing of multiple components. The core of the system solves the problems of large errors, low efficiency, and cross-contamination in traditional manual batching through the closed-loop design of "independent feeding - synchronous weighing - centralized unloading".

Advantages of Multi-material vacuum weighing system

It adopts a fully enclosed design to eliminate cross-contamination, has a one-button changeover function, is suitable for multi-variety production, and greatly improves production accuracy and efficiency.

Multi-component synchronous control: The proportioning error of 8 materials is controlled within ±0.3%, which is better than traditional manual step-by-step weighing.

Dynamic compensation technology: For powders with relatively high fluidity such as flour and calcium carbonate, the suction speed can be automatically adjusted through an automatic algorithm to ensure the consistency of the proportion.

High-speed cycle capability: The complete weighing-unloading cycle of multiple materials takes only 1 minute, and the annual production capacity can reach 1,500 tons.

One-button changeover function: More than 100 sets of production parameters can be stored through the recipe management system, and different product switching can be completed in 10 minutes, which is suitable for small-batch production of multiple varieties.

Fully enclosed isolation design: Each material channel has an independent vacuum circuit, and CIP online cleaning is automatically started after unloading.

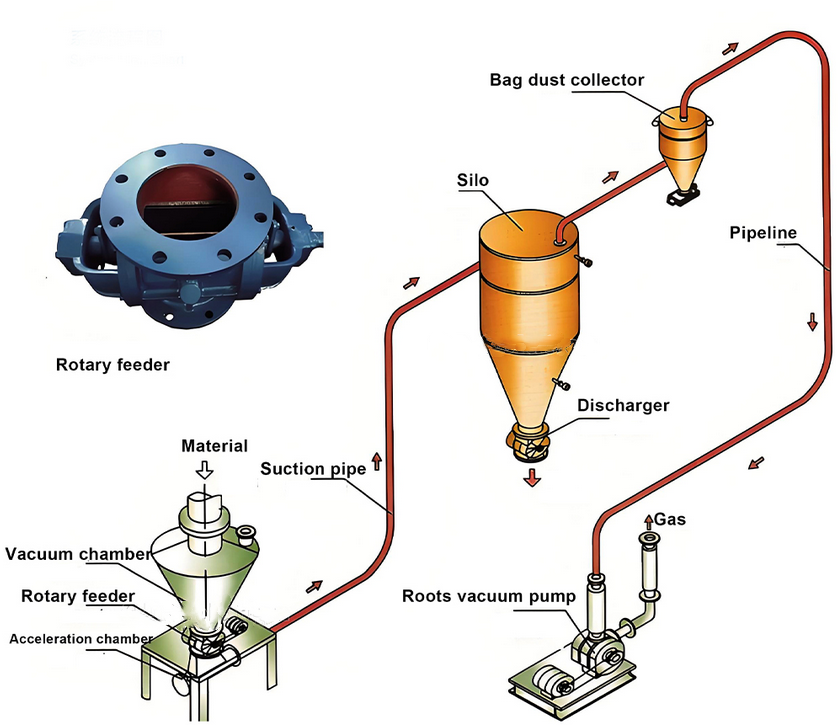

Multi-material vacuum weighing system composition structure

The multi-material vacuum weighing system is mainly composed of the following core components.

Feeding station or material storage silo: used to store different types of powder or granular materials, usually equipped with dust prevention devices to ensure that there is no dust leakage during the feeding process.

Vacuum feeder: The vacuum pump generates negative pressure to suck the material from the storage silo into the conveying pipeline to achieve fast and dust-free material transportation.

Weighing device: High-precision weighing sensor is used to monitor the material weight in real time to ensure that the measurement accuracy reaches one thousandth or even higher.

PLC controller: As the main system of the system, it is responsible for coordinating the work of various components to achieve automatic control and data recording.

Dust removal system: Through filter elements or bag dust collectors, dust generated during transportation is collected to keep the on-site environment clean.

Working principle of multi-material vacuum weighing system

After the vacuum pump is started, negative pressure is formed in the conveying pipeline, and the material is sucked from the storage bin and conveyed to the weighing hopper. The weighing sensor monitors the weight of the material in real time. When the set value is reached, the PLC controller turns off the vacuum pump to stop conveying. The system can accurately weigh and proportion multiple materials according to the preset formula in turn. Finally, the material is put into the downstream equipment through the discharge valve to complete the feeding process.

What materials can the multi-material vacuum weighing system convey?

With its multi-channel independent metering and precise proportioning capabilities, the multi-material vacuum weighing system is suitable for a wide range of material types and can meet different types of materials.

Powder materials: covering fine powders (such as flour, milk powder, carbon powder, particle size 50-200 mesh) and ultrafine powders (such as graphene, fumed silica, particle size <10μm).

Granular materials: suitable for regular particles (plastic particles, feed particles, etc., with a particle size of 0.5-3mm) and irregular particles (catalyst carriers, crushed materials).

Flake/fibrous materials: For flaky materials (mica flakes, dehydrated vegetables) and short fiber materials (cellulose, carbon fiber segments), flexible pneumatic conveying technology is used to prevent material entanglement and jamming, ensuring smooth conveying.

Mixed materials: can handle powder and particle mixtures (premixed feed, seasonings) and wettable powders containing trace amounts of liquid. Through a multi-stage separation and remixing system, the material ratio is accurately controlled.

What is the accuracy of the multi-material vacuum weighing system?

The multi-material vacuum weighing system achieves high-precision material ratio and metering with advanced sensors and intelligent algorithms.

Multi-component synchronous metering accuracy: The ratio error of 2-8 materials can be controlled within ±0.3%, which is 5 times higher than the ±1.5% error of traditional manual step-by-step weighing.

Accuracy after dynamic compensation: For materials with large fluidity differences (such as flour and calcium carbonate), the PID algorithm automatically adjusts the suction speed to ensure the consistency of the ratio and further guarantee the overall metering accuracy.

Industry-specific accuracy: In the pharmaceutical industry, when the proportion of acetaminophen, chlorpheniramine maleate and other ingredients used in cold compound tablets, the system weighing accuracy can reach ±0.2%, which significantly improves the content uniformity qualification rate of compound preparations.

Multi-material vacuum weighing system application scenarios

The multi-material vacuum weighing system has been widely used in many industries with strict material handling requirements due to its advantages such as high-precision metering, dust-free conveying and flexible ratio.

Application in the pharmaceutical industry: In the production of drugs, for the ratio of APIs and excipients, the system can accurately weigh a variety of raw materials to ensure accurate ratios, thereby ensuring the quality and efficacy of drugs.

Application in the food industry: The food industry also has strict requirements on the accuracy of raw material ratios. In the production of formula foods such as infant formula and nutritional supplements, multi-material vacuum weighing systems can ensure that the amount of each ingredient added is accurate, while avoiding dust pollution and ensuring food safety.

Battery material industry application: In the production of lithium batteries, multi-material vacuum weighing systems are essential for the preparation of positive and negative electrode materials and electrolytes. The system can achieve accurate weighing and mixing of multiple raw materials, which directly affects the battery's capacity, cycle life and other performance, thereby improving the overall performance of the battery.

Building materials industry application: In the building materials industry, multi-material vacuum weighing systems are also widely used. In concrete production, the system can achieve accurate weighing and mixing of multiple admixtures, which has an important impact on the performance of concrete and improves the quality of concrete.

Feed processing industry application: The accuracy of raw material ratios in the feed processing industry cannot be ignored. Multi-material vacuum weighing systems can achieve accurate weighing and mixing of multiple raw materials, ensure the accuracy of feed formulas, and directly affect the nutritional value of feed and animal growth performance.

What factors need to be considered when purchasing a multi-material vacuum weighing system?

When purchasing a multi-material vacuum weighing system, you need to consider multiple factors such as accuracy, applicability, and cost to ensure that the equipment meets production needs.

Weighing accuracy: The system's ratio error for multi-component materials should be controlled within ±0.3%, and the accuracy of high-precision sensors must reach ±0.1% FS to meet the precise measurement needs of different materials.

Number of channels: Select according to the number of types of materials to be processed in production. For example, compound preparation production may require 5-8 channels, while simple mixing scenarios require 2-3 channels.

Processing capacity: Pay attention to the system's weighing-unloading cycle and production capacity. For example, in the food industry, if the production capacity needs to be increased from 800kg/h to 2.5t/h, you need to choose equipment with corresponding processing capacity.

Material adaptability: Confirm the equipment's processing capacity for materials of different forms (powder, granules, flakes, etc.). For example, when processing ultrafine powders, it is necessary to have an anti-flying design, and when processing granular materials, it is necessary to ensure a low breakage rate.

Multi-material vacuum weighing system manufacturer

As a professional manufacturer of multi-material vacuum weighing system, Dahan Machinery provides customized solutions for simultaneous measurement of 2-8 materials, suitable for complex materials such as powders and granules, and has special configuration capabilities such as explosion-proof and aseptic. The company provides free material testing to help customers reduce production costs by an average of 35%, and is the preferred partner for intelligent measurement of powders.

The multi-material vacuum weighing system redefines the standard of multi-component material processing through the three-dimensional innovation of "precise measurement + intelligent linkage + pollution control", which is especially suitable for modern smart factories with strict requirements on ratio accuracy, production efficiency and compliance.