Vertical Single Shaft Ribbon Mixer

The vertical single shaft ribbon mixer consists of internal and external spiral ribbons, which are designed to continuously and fully mix materials. It is widely used as a mixing equipment in the chemical, food, pharmaceutical, building materials and other industries. It is mainly used for uniform mixing of dry powder, granules and other solid materials.

Mixing time: 8-20 minutes Frequency: 50HZ, 60HZ Mixing speed: 15-60r/min One-time mixing: 100-6000 (kg) (if more than 6000kg can be customized as needed) Use: It can handle a variety of materials, including powders, granules, pastes and viscous materials. Suitable for food processing, pharmaceuticals, chemicals, plastics and construction industries

What is a vertical single shaft ribbon mixer?

The vertical single shaft ribbon mixer is a common powder mixing equipment, which is mainly used to evenly mix powdery, granular or fibrous materials of different particle sizes and densities. Its main features are a vertical cylinder and a single vertically arranged ribbon stirring shaft. The ribbon is usually a double-layer or multi-layer structure, which lifts and throws the material in the barrel by rotating to achieve the purpose of mixing. The vertical single-shaft ribbon mixer is an ideal choice for mixing small and medium batches of multi-variety materials due to its compact structure, high mixing efficiency and easy maintenance.

Difference between vertical single shaft ribbon mixer and horizontal ribbon mixer

| Features | Vertical single shaft ribbon mixer | Horizontal ribbon mixer |

| picture |

|

|

| Structure | Cylindrical or conical vertical barrel, single vertical center shaft, spiral ribbon blades | Horizontal U-shaped or O-shaped barrel, single or double horizontal shaft, spiral ribbon blades |

| Mixing motion | Three-dimensional mixing, the material moves in the vertical direction and circumferential direction | Three-dimensional mixing, the material moves mainly in the horizontal direction and circumferential direction |

| Mixing uniformity | Usually can achieve good uniformity, especially for density differences Small materials | High mixing efficiency, strong adaptability to a variety of materials |

| Applicable materials | Applicable to powdery and granular materials, good mixing effect for light and fluffy materials | Applicable to powdery, granular, paste, and even small amounts of liquid materials |

Working principle of vertical single shaft ribbon mixer

Material circulation: When the outer ribbon rotates, the bottom material is lifted upward. The inner ribbon pushes the top material downward to form a two-way convection.

Mixing mechanism: The material circulates in the vertical direction to achieve a wide range of position exchange. As the spiral shaft rotates, the ribbon mixer produces a three-dimensional mixing effect. The friction between the ribbon and the cylinder wall and between the materials generates shear force. The outer ribbon usually moves the material upward along the edge, while the inner ribbon moves the material downward toward the center. This countercurrent flow ensures thorough and uniform mixing.

Mixing effect: By adjusting the speed, ribbon angle and mixing time, high uniformity mixing can be achieved (mixing uniformity can reach more than 95%).

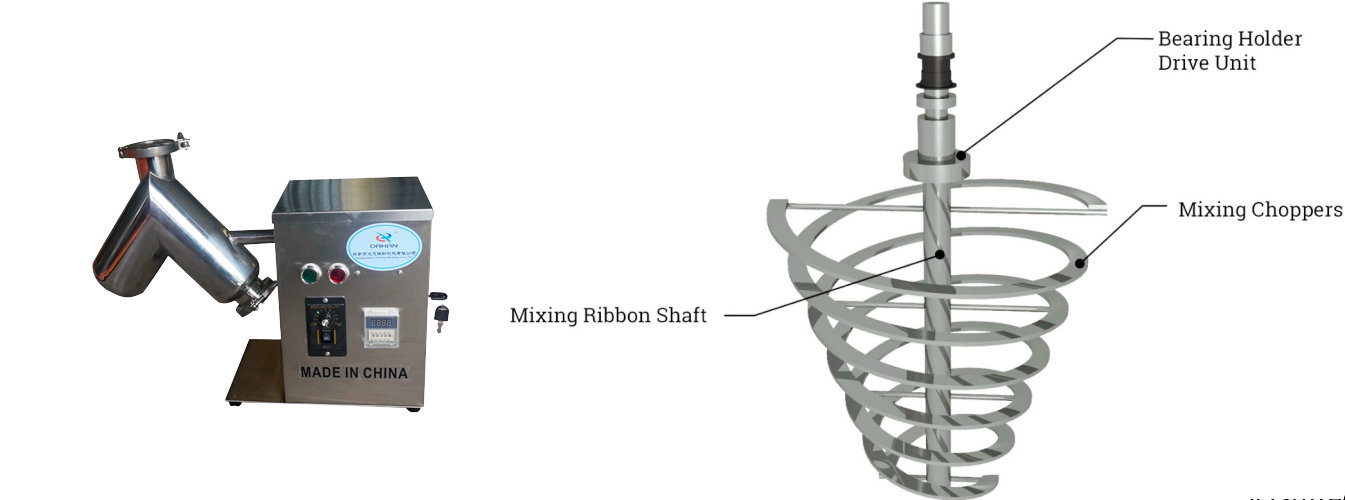

Structure of vertical single shaft ribbon mixer

Single-shaft design: The main shaft is simple, usually composed of a single shaft and a specially designed toothed ribbon, driven from the top

Spiral structure: The variable pitch, discontinuous spiral blades can exert different forces on the material at different positions, so that the material has both axial movement and radial diffusion during the mixing process, improving the mixing effect.

Barrel design: The working barrel is generally a cylindrical body with a conical bottom

Seal structure: A suitable shaft seal structure is used for each application, and the shaft seal is installed away from the product to ensure that the tried and tested agitator seal is well used to prevent material leakage

Discharging device: There is a flush-mounted discharge flap valve at the bottom of the barrel, and other types of valves can also be customized according to needs

What are the advantages of a vertical single shaft ribbon mixer

Good mixing effect: It can achieve a variety of mixing methods such as convection, turbulence and shear, so that the material can reach a high standard of mixing uniformity in a short time.

Solve the problem of serious residue: Many conveying equipment tends to leave a lot of material residue inside after unloading, causing waste. Many vertical single shaft ribbon mixers adopt a conical bottom design, which is conducive to the complete discharge of materials under gravity and reduces residue.

Effectively deal with the problem of material agglomeration: Many powdered or granular materials are prone to agglomeration due to factors such as humidity, static electricity, and pressure during transportation or storage, resulting in poor fluidity and difficulty in uniform mixing and unloading. The rotating ribbon will generate a certain shear force, which helps to break up smaller agglomerates and restore the fluidity of the material. The lifting and lowering movement of the ribbon forms a strong material convection, which continuously disperses the agglomerated materials.

Wide range of applications: It can be used to mix various solid powders such as fine chemicals, dyes, fertilizers, shear-sensitive crystalline powders, and can also be used in the process of mixing liquids into solids. It can also handle dry powders, wet suspensions, and various forms of materials such as liquids, pastes, and doughs.

Technical specifications of vertical single shaft ribbon mixer

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Application of vertical single shaft ribbon mixer

Vertical single shaft ribbon mixer is widely used in many industries due to its unique structure and mixing method, mainly in occasions that require gentle mixing, high uniformity, easy cleaning and space saving.

① Food industry: Mix flour, yeast, sugar, salt, oil and other raw materials to evenly distribute the various ingredients, lay the foundation for subsequent fermentation, baking and other processes, and ensure the taste and quality of bread and pastries.

② Pharmaceutical industry: For Chinese medicine compound preparations, mix various Chinese medicinal materials extracts, powders, etc. together to evenly distribute the effective ingredients and improve the quality stability and consistency of Chinese medicine preparations.

③ Chemical industry: Mix pigments, resins, solvents, additives and other raw materials to evenly disperse the pigments in the resins and solvents to form coating products with stable performance and uniform color. In the production of plastic particles, different types of plastic raw materials and additives (such as plasticizers, stabilizers, colorants, etc.) are mixed evenly to improve the performance of plastics and meet the needs of different application scenarios.

④ Feed industry: Mix corn, soybean meal, fish meal, minerals, vitamins and other feed raw materials to provide livestock and poultry with comprehensive and balanced nutrition and promote the growth and development of livestock and poultry.

Manufacturer of vertical single shaft ribbon mixer

Dahan Machinery specializes in the production of mixers, dryers, conveyors and other equipment. Its products are widely used in chemical, food, pharmaceutical, building materials and other industries. Our company focuses on high-efficiency and energy-saving equipment, low-residue design, and supports non-standard customization. When choosing a vertical single shaft ribbon mixer manufacturer, it is recommended to consider the following factors:

Technical strength: Choose a manufacturer with advanced technology and rich experience to ensure the performance and stability of the equipment.

Product quality: Pay attention to the manufacturer's product quality control system and choose products that have passed ISO and other quality certifications.

After-sales service: Choose a manufacturer that provides perfect after-sales service to ensure that the equipment receives timely technical support and maintenance during use.

I hope the above information can help you. When choosing, it is recommended that you make a comprehensive consideration based on your own needs and actual situation and choose the vertical single shaft ribbon mixer that best suits you.