Seeds Coarse Crusher

It is a grinder used to crush seeds of different hardness or fibrousness to the ideal mesh size. It crushes the seeds through mechanical force without causing loss of nutritional value. The whole machine is made of 304 stainless steel, which is clean, hygienic and easy to clean. Its price ranges from $300 to $5800.

Discharge particle size: 1-300 mesh adjustable

Output: 5-300kg/h

Type: hammer type, claw type, laboratory use

What is Seeds Coarse Crusher?

The Seeds Coarse Crusher is a pulverizer designed to mechanically crush seeds to a size of 300 mesh or less. It is commonly used for seed pretreatment before processing, crushing whole seeds into uniform granules or powder, providing suitable raw materials for subsequent processes such as oil extraction, milling, feed pelleting, and breeding trials, while also reducing the inefficiency and nutrient loss of manual crushing. It can adjust the crushing fineness based on different seed characteristics, such as oil content and hardness, to achieve coarse, medium, or fine crushing. With a crushing capacity ranging from 5-500g per laboratory load to 0.1-5 tonnes/hour at industrial levels, it can be used in grain and oil processing, feed production, agricultural laboratories, and other applications to crush a variety of seed types, including wheat, corn, rapeseed, and soybeans.

What types of Seeds Coarse Crusher are there?

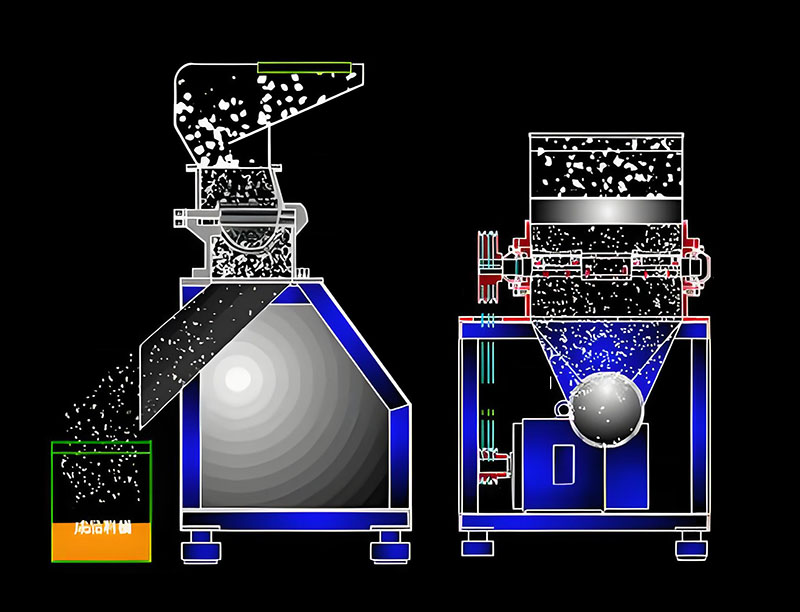

The Seeds Coarse Crusher has different models for crushing seeds of different hardness types, mainly including hammer type, claw type, and laboratory small sample seed crushing type. Choose the appropriate model according to the properties of the seeds and the application scenario.

Hammer-type Seeds Coarse Crusher: A motor drives a high-speed rotor at 5,000-10,000 rpm. The hammers on the rotor break the seeds into small pieces through impact and vibration. It is commonly used for crushing medium-hard, non-sticky seeds such as wheat, corn, rice, and sorghum. The crushing capacity ranges from 0.1 to 5 tons/hour, and the crushed particle size ranges from 1 to 5 mm.

Claw-type Seeds Coarse Crusher: The claws on the rotor work with fixed teeth inside the housing to shear, tear, and gently impact the seeds, resulting in finer particle size. It is suitable for oily, slightly fibrous, or hard-coated seeds, such as rapeseed, soybeans, and peanuts (after shelling). The crushing capacity ranges from 0.05 to 3 tons/hour, and the screen aperture is adjustable from 0.5 to 3 mm.

Laboratory Seeds Coarse Crusher: Generally, the model is relatively small, mostly desktop. It uses high-speed blade cutting, grinding or micro-hammer impact, combined with a fine screen, to achieve precise crushing of small batches of seeds. It is often used for small sample seeds in the laboratory, such as wheat, corn, rapeseed, and forage seeds for breeding experiments (single processing volume ≤ 500g). The crushing particle size is 0.1-2 mm and the crushing capacity is 0.1-1 kg/h.

What are the advantages of Seeds Coarse Crusher?

The Seeds Coarse Crusher has a fast crushing speed and can quickly complete large-scale seed processing. The crushed particle size is uniform, meeting the precise needs of subsequent germination experiments, ingredient extraction, etc.; at the same time, it reduces labor costs, is easy to operate, and can also reduce seed loss, effectively improving the efficiency and processing quality of seed crushing.

No cross-contamination: The whole machine is made of 304 stainless steel, which can ensure that different seed samples will not contaminate each other, and each sample can be quickly cleaned after processing

Strong adaptability: It can handle special seeds such as high moisture (such as freshly harvested seeds) and high oil content (such as rapeseed, peanuts)

Controllable particle size: By changing the screen or adjusting the parameters, different crushing finenesses of 20-300 mesh (0.075-0.8mm) can be obtained to meet different crushing needs.

Low moisture loss: The closed design reduces moisture evaporation during the crushing process, ensuring the accuracy of subsequent moisture measurement.

The difference between Seeds Coarse Crusher and ordinary Coarse Crusher

| Comparison items | Seeds Coarse Crusher | Ordinary crushing equipment |

| Particle size control | Precisely adjustable (1-300 mesh) | Usually fixed or limited adjustment |

| Sample adaptability | Optimized for seed characteristics | General design, regardless of seed characteristics |

| Heat-sensitive treatment | Low temperature option to prevent ingredient damage | Prone to heat, which may damage ingredients |

| Moisture retention | Closed system reduces losses | Usually open, moisture is easily lost |

| Cross contamination | Anti-contamination design | Prone to residue, difficult to clean |

| Data accuracy | Ensure detection accuracy | May affect the test results |

| Convenience of operation | Automation and humanized design | Usually manually operated |

| Safety performance | Multiple protection measures | Relatively simple safety design |

What is the principle of Seeds Coarse Crusher?

When Seeds Coarse Crusher is working, the seeds first enter the equipment from the feed port, and then the high-speed rotating blades or grinding beads apply shear force and impact force to the seeds to break the seed tissue. The seeds that meet the crushing specifications are discharged from the discharge port, and those that do not meet the specifications are crushed again.

Seeds Coarse Crusher parameters

| Parameters | TP-100 (laboratory type) | JFSD-200 (medium-sized general purpose) | GD-300 (high-yield type) | TAJ-500 (air flow milling type) |

| Applicable seed types | Grains such as wheat, rice, and corn | Beans, oil seeds (soybeans, peanuts) | Hard seeds (coffee beans, nuts) | High precision requirements (medicinal, scientific research) |

| Feed particle size | ≤10mm (whole seeds) | ≤15mm (can be crushed with shell) | ≤20mm (coarse crushing pretreatment) | ≤5mm (needs pre-crushing) |

| Discharge particle size | 20-100 mesh (0.15-0.8mm) | 40-120 mesh (0.12-0.4mm) | 10-60 mesh (0.25-2mm) | 100-300 mesh (0.05-0.15mm) |

| Processing capacity | 5-10kg/h | 20-50kg/h | 100-300kg/h | 5-15kg/h (ultra-fine grinding) |

| Motor power | 370W | 1.5kW | 5.5kW | 3kW (gas source separately) |

| Speed | 2800rpm | 2400rpm | 1800rpm | No rotor (air flow collision) |

| Screen configuration | Φ0.5/1.0/2.0mm optional | Multi-specification stainless steel screen | Customizable coarse crushing screen plate | No screen (classifying wheel control) |

| Noise level | ≤75dB | ≤85dB | ≤90dB | ≤70dB (enclosed design) |

| Equipment weight | 25kg | 80kg | 220kg | 150kg |

| Special functions | Anti-splashback design | Oil anti-stick coating | Continuous feeding + automatic slag discharge | Low temperature crushing (≤40℃) |

What are the applications of Seeds Coarse Crusher?

Seeds Coarse Crusher can crush a wide range of seed types, including cereals (such as wheat, corn, rice), oilseeds (such as soybeans, peanuts, rapeseed), grains (such as sorghum, oats, buckwheat), and various vegetable seeds (such as cabbage, radish), forage seeds (such as alfalfa, ryegrass), etc., whether it is hard nut seeds or softer seeds. It has a wide range of application scenarios. In the field of agricultural seed production, seeds can be crushed to a suitable particle size for seedling mixing; in feed processing, oilseeds can be crushed to make concentrated feed; in food processing, grain seeds can be crushed to make flour or beverage raw materials; in scientific research experiments, it can also be used for pretreatment before seed component analysis to meet the seed crushing needs in different fields.

What is the best way to crush seeds?

The best way to crush seeds is to use Seeds Coarse Crusher, because it can adjust the crushing particle size and crushing method (such as hammer type for impact crushing, claw type for shear crushing, etc.) according to the hardness, particle size, viscosity, moisture content and other characteristics of different types of seeds such as wheat, rapeseed, sesame, etc., which can reduce the loss of seed nutrients and reduce the damage to seed components caused by high temperature. In addition, the crushing is highly uniform, which is conducive to subsequent processing such as oil extraction and breeding. The machine is made of 304 stainless steel, which is easy to clean and can reduce cross contamination.

Different types of seed crushing solutions

| Seed Type | Applicable crusher type | Recommended Crushing Size | Subsequent Main Applications | Core Reason for Compatibility |

| Wheat | Hammer Mill | 2-3 mm | Flour Milling, Feed Making | The hammer's moderate impact force breaks hard grains into uniform, small pieces, preventing flour clumping caused by over-grinding. The efficiency reaches 1.5-2 t/h. |

| Rapeseed | Claw-Type Grinder | 1-1.5 mm | Oil Pressing and Extraction | The claw's precise shearing force breaks the seed coat without squeezing out excess oil, reducing residue blockage during subsequent oil extraction. The crushing uniformity reaches ≥95%. |

| Corn | Roller + Hammer Combination Mill | 3-5 mm | Feed pelleting, winemaking | The corn kernels are first crushed by rollers, then crushed by hammers to prevent whole kernels from being lost. Suitable for corn with a moisture content of up to 15%, with a production capacity of 3-4 t/h. |

| Soybeans | Claw-type crusher | 2-4 mm | For making soy flour and soy products | The claws cut through soybean fibers, leaving the crushed granules free of hard cores. The high protein content in soybeans also prevents them from sticking to the machine chamber, reducing cleaning frequency by 50%. |

Seeds Coarse Crusher Manufacturers

MACHRISE Machinery specializes in the research, development, and production of seed crushers. Our comprehensive product range includes hammer crushers, claw crushers, dust removal crushers, and ultrafine crushers, suitable for crushing all types of seeds in seed processing applications. We offer bottom and side discharge options to meet space constraints. We also offer customized services and add-on features, such as mobile, explosion-proof, and vacuum-operated models, depending on the type of seed being crushed and the application.

Coarse crusher

Coarse crusher Spice Crusher

Spice Crusher Chinese Herb Grinder Machine

Chinese Herb Grinder Machine