Electromagnetic Silver Induction Furnace 2600 Degree Vacuum Melting Furnace

The melting temperature is precisely controlled up to 2600℃ and the operation is carried out in a high vacuum environment to effectively remove impurities and gases, ensuring that the smelted silver has extremely high purity and uniformity.

Price: $600.00-$76,000.00

Voltage: 380V three-phase

Power: 40kW

Vacuum chamber: stainless steel

Maximum temperature: 2800℃

What is Electromagnetic Silver Induction Furnace 2600 Degree Vacuum Melting Furnace?

Electromagnetic Silver Induction Furnace 2600 Degree Vacuum Melting Furnace, designed for high purity applications in jewelry manufacturing, electronic components and advanced materials research.

Unlike conventional melting systems, our Electromagnetic Silver Induction Furnace 2600 Degree Vacuum Melting Furnace creates an oxygen-free environment to prevent oxidation and contamination of precious silver, gold, platinum and other precious metals. Electromagnetic induction heating provides fast, uniform heating and precise temperature control up to 2600°C, far higher than standard industrial furnaces.

Ultra-high temperature capability (2600°C) for melting high melting point alloys.

Vacuum environment (5×10⁻³Pa) prevents oxidation and ensures metal purity.

Electromagnetic stirring to ensure uniform alloy composition.

Programmable temperature control with an accuracy of ±1°C.

Advanced safety systems, including over-temperature protection and emergency cooling.

What are the advantages of Electromagnetic Silver Induction Furnace 2600 Degree Vacuum Melting Furnace?

High purity: The vacuum environment (up to 5×10⁻³Pa) eliminates contact with oxygen, preventing oxidation and gas absorption that could affect metal quality.

Precise temperature control: The PID control system maintains temperature stability within ±1°C, and electromagnetic induction heating allows for rapid response to temperature adjustments.

Energy efficiency: Induction heating systems are 85-90% more energy efficient, much higher than resistance-heated furnaces. The focused electromagnetic field heats only the metal charge, not the entire furnace chamber.

Fast melting cycle: With direct energy transfer through electromagnetic induction, melting times are typically 40-60% faster than conventional furnaces. A 30 kg load of silver can reach pouring temperature in 20 minutes.

How does the Electromagnetic Silver Induction Furnace 2600 Degree Vacuum Melting Furnace work?

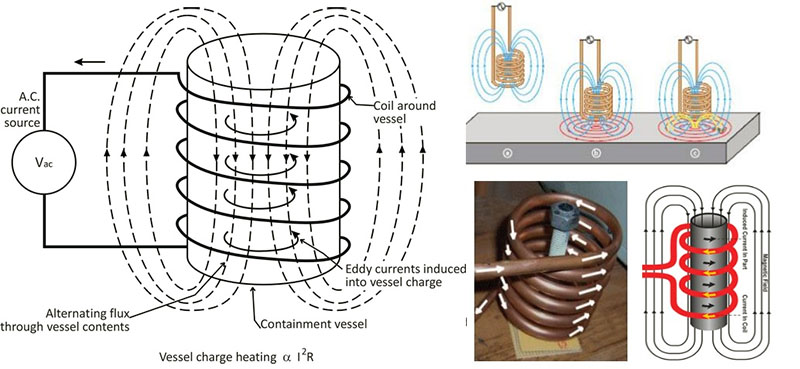

Electromagnetic Silver Induction Furnace 2600 Degree Vacuum Melting Furnace uses the principle of electromagnetic induction heating, whereby alternating current (2500Hz) is passed through a copper coil, creating a rapidly alternating magnetic field. When a conductive material such as silver is placed in this magnetic field, eddy currents are generated in the metal, resulting in resistive heating.

The vacuum system creates an oxygen-free environment by evacuating the furnace chamber to 5×10⁻³Pa, preventing oxidation and gas absorption during the melting process. This is particularly important for silver, which easily absorbs oxygen at high temperatures.

Electromagnetic Silver Induction Furnace 2600 Degree Vacuum Melting Furnace Parameters

General Specifications

| Parameter | Value |

| Model | ZG-0.03L (30kg capacity) 1 |

| Maximum Temperature | 2600°C |

| Working Temperature Range | 500-2600°C |

| Heating Rate | Up to 200°C/min |

| Temperature Control Accuracy | ±1°C |

| Chamber Material | 304 Stainless Steel |

Power System

| Parameter | Value |

| Total Power | 130KW 1 |

| Input Voltage | 380V 3-phase |

| Frequency | 50/60Hz |

| Induction Power | 100KW 1 |

| Induction Frequency | 2500Hz |

Vacuum System

| Parameter | Value |

| Ultimate Vacuum | 5×10⁻³Pa 1 |

| Working Vacuum | 5×10⁻²Pa |

| Leak Rate | <4.0Pa/h 1 |

| Pumping Time (to working vacuum) | ≤20min |

Cooling System

| Parameter | Value |

| Water Flow Rate | 15m³/h 1 |

| Inlet Water Temperature | ≤30°C |

| Outlet Water Temperature | ≤35°C |

| Water Pressure | 0.2-0.3MPa |

Physical Dimensions

| Parameter | Value |

| Furnace Dimensions (L×W×H) | 4500×3000×4000mm 1 |

| Net Weight | ~5000kg |

| Installation Area | ≥30m² |

What are the applications of Electromagnetic Silver Induction Furnace 2600 Degree Vacuum Melting Furnace?

Jewelry manufacturing: high-purity silver and gold casting, platinum group metal processing, custom alloy development, complex design investment casting

Electronics industry: silver contact production, solder alloy preparation, semiconductor material processing, sputtering target manufacturing

R&D: new material synthesis, metallurgical research, alloy phase diagram research, high-temperature material testing

Solar energy: silver paste for photovoltaic cells, conductive grid production, high-purity silicon processing

Medical devices: dental alloy preparation, surgical instrument manufacturing, implant material development

Aerospace: high-temperature alloy development, turbine component precision casting, special brazing materials

Vacuum environment is particularly suitable for: active metals (titanium, zirconium, hafnium), refractory metals (tungsten, molybdenum, tantalum), oxygen-sensitive alloys, ultra-high purity requirements