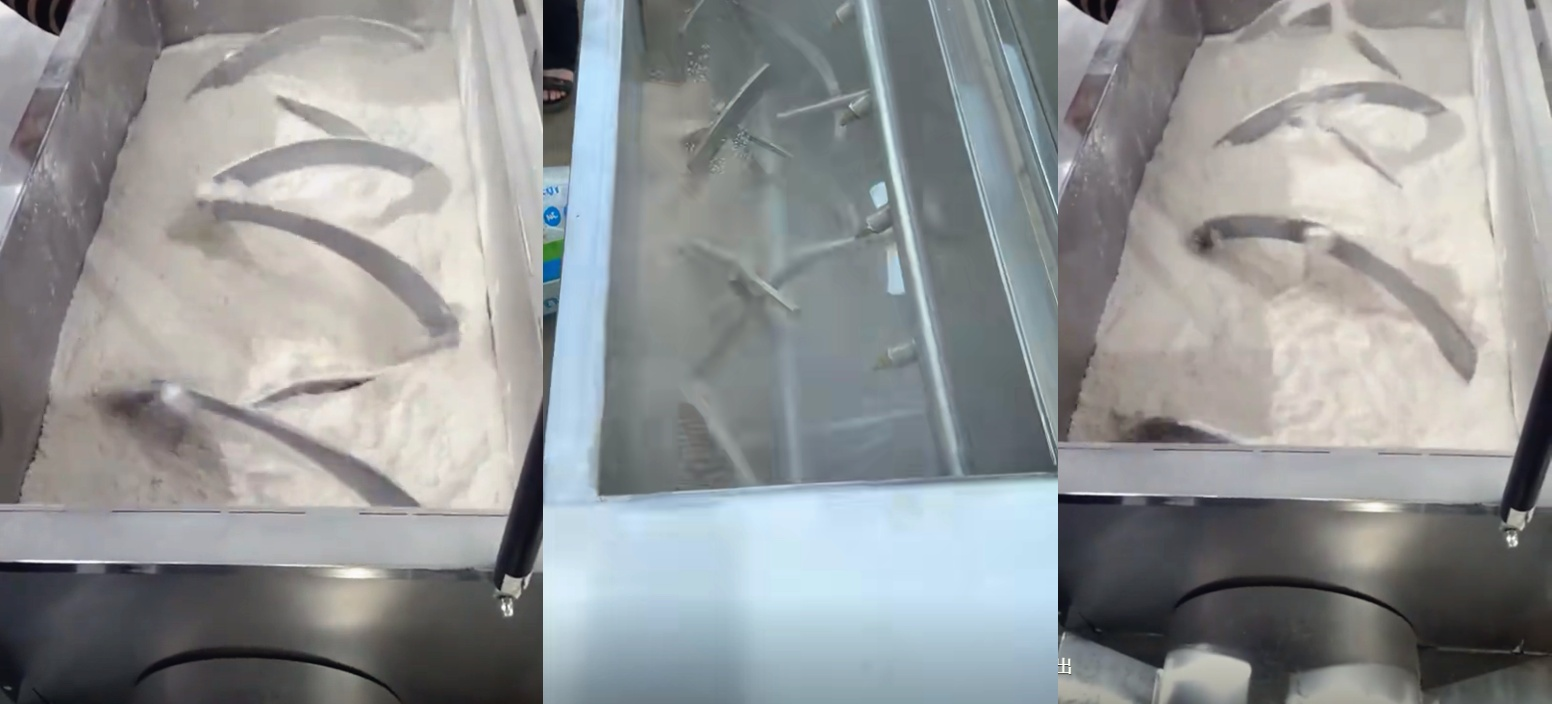

1000L stainless steel ribbon mixer for milk powder raw materials

Tuesday July-01 2025 15:19:41

Due to the fine particle size of milk powder, general fluidity, easy to absorb moisture and agglomerate, and easy to raise dust, the mixing process requires high mixing uniformity and mildness. 1000L stainless steel ribbon mixer for milk powder raw materials adopts a horizontal cylinder structure, with double-layer ribbon blades inside. The outer ribbon pushes the material from both ends to the center, and the inner ribbon pushes the material from the center to both ends, realizing the three-dimensional circulation mixing of the material in the radial and axial directions, effectively preventing stratification and segregation.

The main body of the equipment is made of SUS304 or SUS316L food-grade stainless steel, and the inner wall is mirror-polished to avoid residue and cross-contamination. The single batch loading volume is 600-800L, and a batch of milk powder raw materials can be evenly mixed within 10-15 minutes. It is suitable for production processes with high cleanliness and high uniformity requirements such as compound milk powder and infant nutrition powder.

Application Examples

A large milk powder production enterprise introduced a 1000L stainless steel ribbon mixer for milk powder raw material for uniform mixing of various milk powder raw materials. During the production process, powdered raw materials of different ingredients such as skimmed milk powder, whole milk powder, lactose, vitamin powder, etc. are accurately measured by the automatic weighing system according to the ratio, and then fed into the mixer in sequence.

After starting the equipment, the internal double spiral belt rotates at high speed, pushing the material to form a convection circulation motion, and realizing rapid and uniform mixing of the raw materials. The entire mixing process is generally controlled to be completed within 10 to 15 minutes, ensuring the full fusion of the milk powder raw materials and avoiding uneven ratios and agglomeration.

What is the working principle of the 1000L stainless steel ribbon mixer for milk powder raw material?

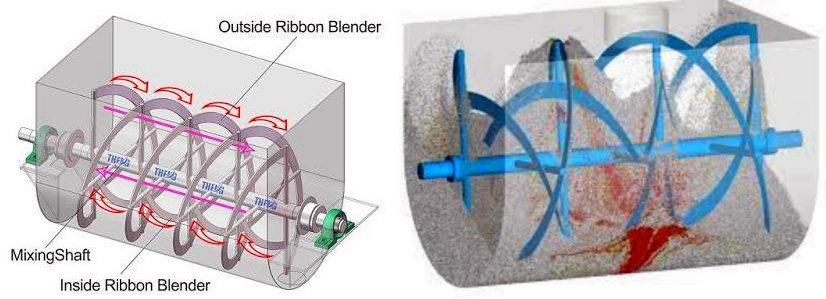

The working principle of the 1000L stainless steel ribbon mixer for milk powder raw material is mainly based on the ribbon mixing structure and convection mixing mechanism, which uses mechanical force to make the material form a three-dimensional motion in the container to achieve uniform mixing.

①Feeding stage: Milk powder raw materials (powder or granules) are put into the container through the top feed port, and the loading capacity is usually 40%-80% of the volume (about 400-800L, to avoid overloading).

②Mixing stage: The inner and outer spiral ribbons rotate in opposite directions (or in the same direction but at different speeds) to form forced convection. The outer spiral ribbon pushes the material to gather in the center, and the inner spiral ribbon spreads the material to both sides to form a circular flow. The material is subjected to shear force in the gap between the spiral ribbon and the container wall, breaking the agglomeration and enhancing the dispersion of the powder. Some models are designed with tilting or flipping functions to further promote the mixing of materials without dead ends.

③Discharging stage: After the mixing is completed, the bottom pneumatic valve or large opening discharge mechanism is started, and the material is quickly discharged under the push of the spiral ribbon, with a low residual rate (<1%).

What are the advantages of the 1000L stainless steel ribbon mixer for milk powder raw material?

When producing compound milk powder (such as infant formula milk powder, adult nutritional powder, etc.), the main ingredients and trace ingredients need to be mixed in proportion. A 1000L mixer can process a batch of standard raw materials at one time with high efficiency. The main raw materials (such as skimmed milk powder) and small proportion ingredients (vitamin powder, iron calcium powder, trace enzymes, etc.) are put into the mixing drum in turn. The motor drives the spiral blades to perform compound spiral motion, which promotes cross convection of the materials in the radial and axial directions, and achieves full and uniform mixing within 10-15 minutes.

The particle size and specific gravity of each component in the milk powder raw material vary greatly. If the stirring method is unreasonable, uneven mixing, stratification or segregation are prone to occur. The mixing method of the double-layer spiral structure with internal and external circulation effectively reduces the sedimentation of heavy components and the floating of light components, and improves the uniformity of the finished powder.

The equipment uses double-layer spiral blades. The inner spiral pushes the material from the center to the outside, and the outer spiral pushes the material from the outer edge to the center, forming an up and down convection cycle, so that powders, particles and other materials can be fully mixed in a short time, ensuring the uniform distribution of each component in the formula, and avoiding local uneven concentration or agglomeration.

Technical specifications of stainless steel ribbon mixer

|

Model |

500L |

1000L |

1500L |

2000L |

3000L |

4000L |

5000L |

6000L |

8000L |

10000L |

|

Volume(L) |

|

|

|

|

|

|

|

|

|

|

|

Loading Factor |

|

|

|

|

|

|

|

|

|

|

|

Motor Power |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Speed |

|

|

|

|

|

|

|

|

|

|

|

Dimension L*W*H(m) |

|

|

|

|

|

|

|

|

|

|

|

Plate thickness mm |

4 |

4 |

5 |

6 |

6 |

8 |

8 |

8 |

8 |

8 |

Selection suggestions for 1000L stainless steel ribbon mixer for milk powder raw materials

When selecting a 1000L stainless steel ribbon mixer for milk powder raw materials, the production demand, equipment efficiency and material characteristics should be comprehensively considered. This model is suitable for small and medium-sized milk powder production lines with a daily batch mixing volume of 15 tons. The single effective loading is about 600-800L. It can complete the uniform mixing of a batch of materials within 10~15 minutes. It is suitable for powder mixing tasks such as whole milk powder, lactose, and vitamin premixes. Its advantages are compact structure and small footprint. The internal and external double ribbon design can achieve high uniformity mixing, and the mixing process is gentle, does not destroy the particle morphology and nutritional activity of milk powder, and effectively prevents stratification and agglomeration.

The 1000L stainless steel ribbon mixer for milk powder is suitable for the mixing of most milk powder raw materials and their derivative powders, especially in the production of formula milk powder, nutritionally fortified milk powder, and special medical purpose milk powder. Its advantage is that it has good adaptability to materials of different density, particle size, and fluidity. When in use, the mixing time (usually 5-10 minutes) and speed can be adjusted according to the characteristics of the raw materials to achieve the best mixing effect.