Ton Bag Feeding Station Process Flow

Friday July-25 2025 17:25:56

Ton Bag Feeding Station is an automated or semi-automated equipment used for unpacking, feeding, and conveying bulk materials in ton bags. The Ton Bag Feeding Station Process Flow is mainly based on "ton bag handling → unpacking → material discharge → screening / crushing → conveying", which is suitable for large-scale powder and granular material processing in chemical, food, pharmaceutical, new energy and other industries.

Preliminary preparation of ton bag feeding station

Before the start of the ton bag feeding station, preliminary preparation is the basis for ensuring efficient operation. The ton bag needs to be accurately lifted to the feeding port by a forklift or a crane, fixed by a positioning device, and the integrity and material status of the ton bag are checked at the same time.

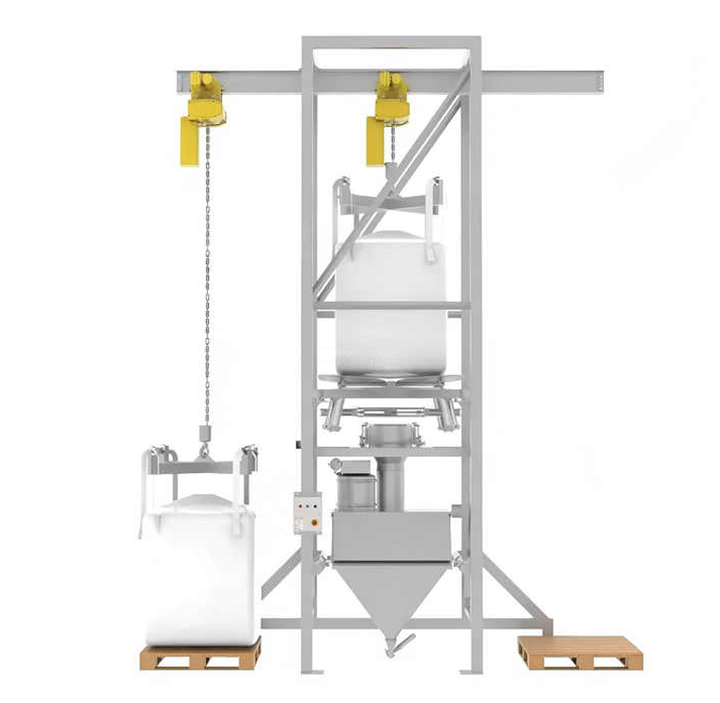

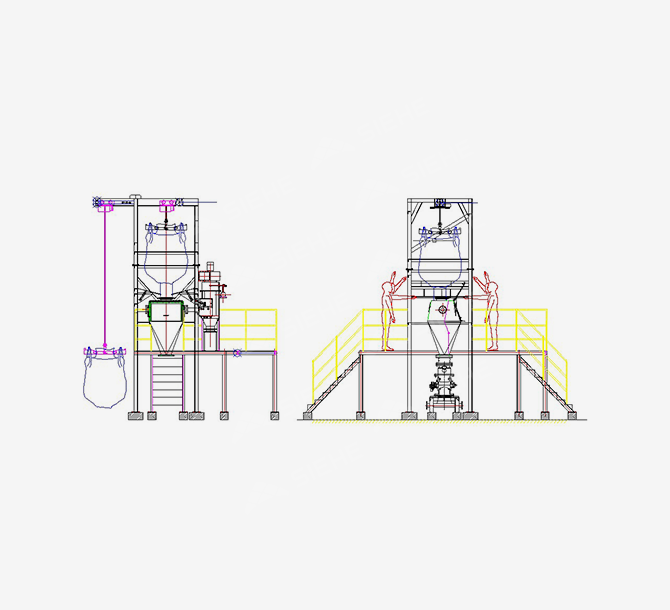

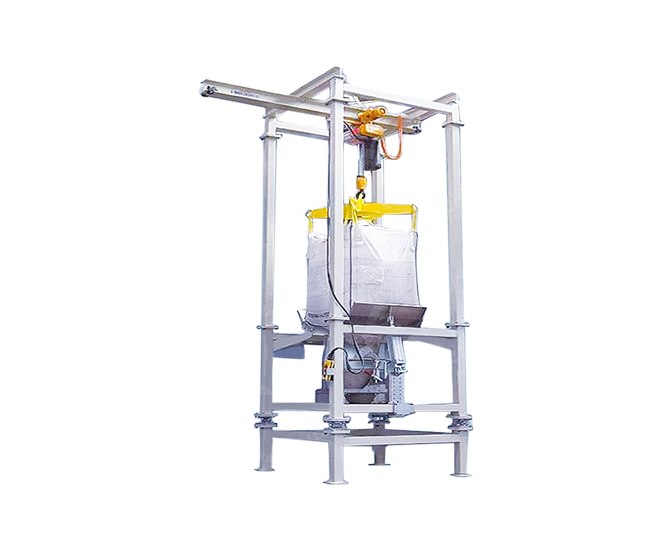

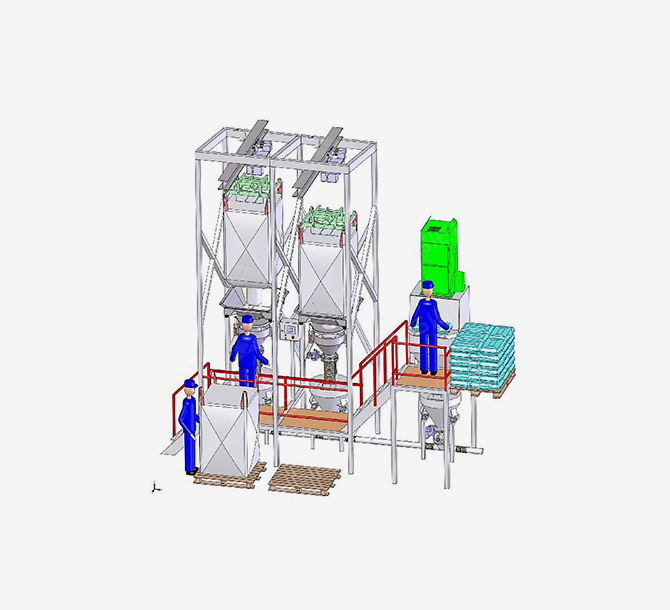

Ton bag transportation and positioning

Use a forklift, a crane or an electric hoist to lift the ton bag filled with materials to the top of the feeding station, and use the positioning device to accurately hang the ton bag directly above the feeding port to ensure that the ton bag is stable and not easy to shake.

Inspection and pretreatment

Check whether the ton bag is damaged and whether the material is agglomerated. If there is agglomeration, it may affect the subsequent feeding. If necessary, clean the surface of the ton bag.

Core feeding process of ton bag feeding station

The core feeding process of ton bag feeding station is the key link to convert bulk materials in ton bags into production-usable state at high speed. It starts with sealed unpacking, integrates leak-proof dust removal, auxiliary unloading, screening and crushing, and realizes the smooth transition of materials from ton bags to subsequent processes.

Unpacking of ton bags

Unpacking of ton bags is a key link in bulk material processing. It connects ton bag storage and transportation with subsequent processing, and disassembles the ton bag outlet manually or mechanically to allow the material to fall safely. This process needs to take into account efficiency and environmental protection, and is often used in conjunction with sealing and dust removal devices, and is widely used in many industries.

Manual/automatic unpacking

Manual operation: Untie the outlet tie at the bottom of the ton bag, or cut the bottom/side of the ton bag to allow the material to fall by gravity.

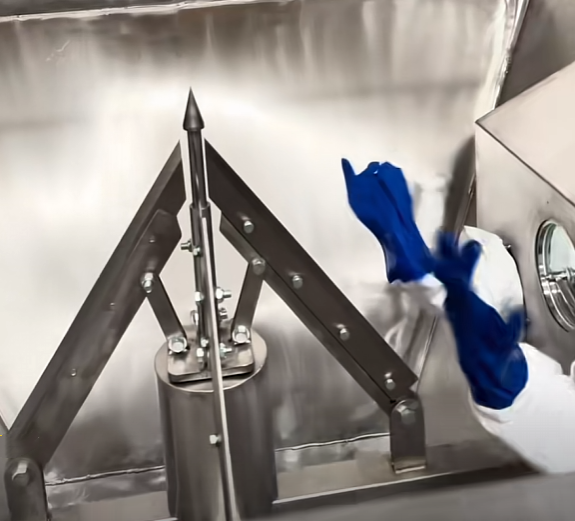

Automatic unpacking: Through mechanical devices such as cutting knives and bag clamps, the cable ties are automatically untied or the ton bags are cut open to reduce manual contact, which is suitable for dusty or toxic materials.

Dust leakage prevention: The feeding port is usually equipped with sealing devices, such as telescopic sleeves and dust covers, and is connected to the dust removal system to prevent the dust generated when the material falls from the outside and protect the working environment.

Material discharge and unloading at the ton bag feeding station

The material discharge and unloading of the ton bag feeding station is the key link between unpacking and subsequent processing. It relies on gravity to dominate, supplemented by vibration, beating and other devices to solve the problem of material retention.

Gravity unloading: The material falls from the ton bag discharge port into the hopper of the feeding station. The hopper is designed to be conical or with an inclined angle to reduce material retention.

Auxiliary unloading device: If the material is viscous and easy to bridge, the lumps can be broken by beating devices, vibration devices or stirring devices to ensure smooth material falling. Some equipment is equipped with the "ton bag lifting and compression" function, which squeezes the ton bag downward through a cylinder or hydraulic device to completely discharge the residual material and reduce waste.

Material screening and crushing of ton bag feeding station (optional)

In the material processing link of the ton bag feeding station, screening and crushing are key processes to ensure the purity and particle size of the material. In the face of impurities and lumps that may be mixed in when the ton bag is unloaded, the screening device accurately filters foreign matter, and the crushing equipment quickly resolves the agglomeration.

Screening:A vibrating screen or grid can be installed under the hopper to filter impurities in the material, such as ton bag fragments and large particle lumps, to ensure the purity of the material.

Crushing:If the material is severely agglomerated, a crushing device such as a toothed roller crusher or a hammer crusher can be added before screening to crush the large pieces of material to the required particle size.

Material transportation at ton bag feeding station

Material transportation at ton bag feeding station is the key link between unpacking and subsequent processes. It receives the materials dropped from the ton bags, and transports the materials accurately, quickly and cleanly to the designated location through pneumatic, mechanical and other methods, combined with pre-treatment such as screening and crushing.

Quantitative/continuous transportation

The processed materials enter the conveying equipment from the bottom of the hopper, and the conveying method is selected according to the subsequent process requirements:

Pneumatic transportation: The airflow is used to transport the materials to the storage tank or the next process through the pipeline, which is suitable for light and dry materials.

Mechanical transportation: Such as screw conveyors, belt conveyors, bucket elevators, etc., which are suitable for heavy or sticky materials.

Measuring transportation: With quantitative feeders and screw feeders, accurate feeding amount control is achieved.

Subsequent processing of ton bag feeding station

After the feeding is completed, the empty ton bag is removed from the hook. If the ton bag is recyclable, it is cleaned and reused; if it is a disposable ton bag, it is processed as required.

Process characteristics of ton bag feeding station

The process of ton bag feeding station is characterized by high speed, health and flexibility. It realizes rapid material feeding through automatic suspension positioning, sealed unpacking and dust control, combined with auxiliary unloading and screening and crushing.

Rapidity: The feeding time of a single ton bag is short, usually 5-15 minutes, and it can operate continuously, which is suitable for large-scale material processing.

Flexibility: It can adapt to ton bags of different specifications, 500-2000kg, and select materials according to material characteristics, including carbon steel and stainless steel.

Safety: Through sealing and dust removal design, the risk of dust explosion and health hazards to personnel are reduced.

The core of the ton bag feeding station is to achieve high-speed, clean and safe feeding of bulk materials through the coherent process of "stable suspension → sealed unpacking → smooth unloading → purification treatment → precise transportation". At the same time, different auxiliary devices can be configured according to industry needs to optimize production efficiency.