Self-dusting pulverizer

It can crush all kinds of materials and automatically remove dust simultaneously to prevent dust pollution. The whole machine is made of stainless steel

Price: $150-$5600

Feed size: greater than 20mm

Production capacity: 60-500kg/h

Discharge particle size: 12-120 mesh

What is a self-dusting pulverizer?

Self-dusting pulverizer is a pulverizer that integrates crushing and dust removal. It can crush dry and brittle materials through high-speed rotating blades or hammers. At the same time, the built-in dust removal system automatically collects dust. Its feed particle size is 6-20mm, and the fineness of the output after crushing can reach 200 mesh, which can meet different process requirements. The output ranges from 50kg/h to 3000kg/h, suitable for small batch or large-scale production. The equipment is made of stainless steel, which is corrosion-resistant and easy to clean, ensuring no pollution and meeting GMP standards.

Compared with traditional crushers, Self-dusting pulverizer has the advantages of high degree of automation, simple operation, energy saving and environmental protection, which can greatly improve material utilization and reduce enterprise production costs.

What types of self-dusting pulverizers are there?

Self-dusting pulverizer can be divided into vertical, horizontal, high-speed and explosion-proof types. You can choose the appropriate equipment according to the crushing material and application scenario.

Vertical Self-dusting pulverizer: suitable for fine crushing, such as medicines, food additives, etc.

Horizontal Self-dusting pulverizer: suitable for high-yield crushing, such as chemical raw materials, feed, etc.

High-speed Self-dusting pulverizer: suitable for ultra-fine crushing, such as metal powders, pigments, etc.

Explosion-proof Self-dusting pulverizer: suitable for flammable and explosive materials, such as certain chemical raw materials

What are the characteristics of a self-dusting pulverizer?

Self-dusting pulverizer is made of all stainless steel, which is clean and sanitary, has high crushing efficiency, automatic dust removal, and no dust pollution. The specific advantages are as follows:

No dust pollution: using bag dust removal + cyclone separation technology, dust recovery rate ≥ 99%, ensuring a clean production environment.

High efficiency and energy saving: optimizing blade design, crushing efficiency increased by 30%, energy consumption reduced by 20%.

All stainless steel material: in line with GMP standards, corrosion-resistant, easy to clean, suitable for food and pharmaceutical industries.

Intelligent control: some models support PLC automatic adjustment, realizing one-button start and stop, fault alarm and other functions.

Low noise operation: adopting shock absorption design, noise ≤ 75dB, improving working environment

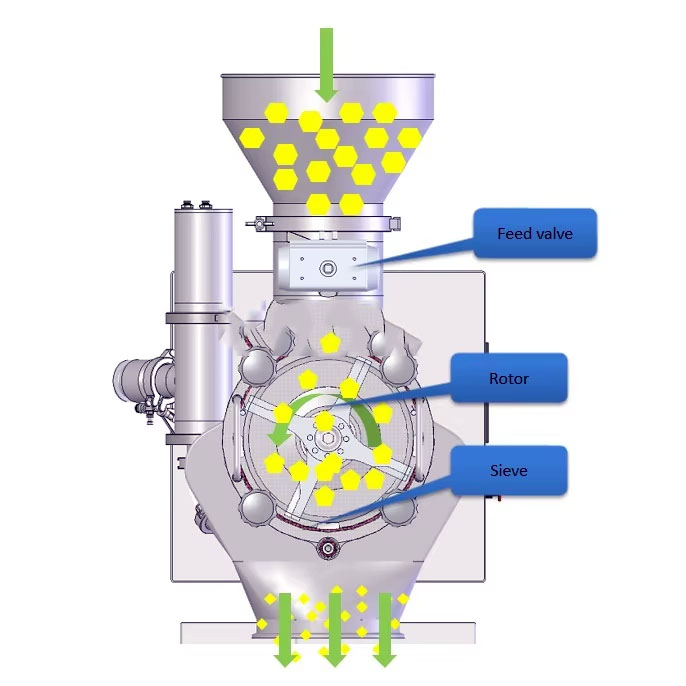

How does a self-dusting pulverizer work?

When the self-dusting pulverizer is working, the material enters the crushing chamber through the hopper. Under the interaction of the high-speed rotating blade and the fixed toothed disc, the material is crushed by shearing, impacting and friction. The crushed material enters the capture bag under the action of centrifugal force, the dust is recovered after being filtered by the bag, and the clean air is discharged. The material that meets the particle size is discharged through the screen, and the coarse particles continue to be crushed.

Self-dusting pulverizer parameters

| Model | Production capacity (kg/h) | Feed size (mm) | Discharge size (mesh) | Power (kW) | Size (mm) |

| JB-20 | 60-180 | ≤6 | 12-120 | 5.88 | 1200×1150×2570 |

| JB-30 | 100-400 | ≤10 | 12-120 | 9.38 | 1250×1200×2570 |

| JB-40 | 200-800 | ≤12 | 12-120 | 12.88 | 1400×1350×2890 |

| GXF-30B | 100-300 | ≤10 | 60-120 | 5.5 | 1200×650×1650 |

Self-dusting pulverizer application

Self-dusting pulverizer is suitable for crushing dry and brittle materials with feed size ≤20mm, including Chinese herbal medicines, food raw materials, chemicals, minerals, etc. Its discharge fineness is adjustable (12-200 mesh) to meet different fineness requirements. It is mainly used in pharmaceutical, food processing, chemical and other industries to achieve the dual goals of efficient crushing and environmentally friendly production.

Pharmaceutical industry: crushing Chinese and Western medicine particles to ensure no cross contamination.

Food industry: processing sugar powder, milk powder, starch, etc., in compliance with food safety standards.

Chemical industry: crushing resin, pigment, titanium dioxide, etc., explosion-proof design to ensure safety.

New energy industry: crushing lithium battery materials, dust controllable.

Environmental protection industry: recycling and reuse of construction waste and slag

Chinese Herb Grinder Machine

Chinese Herb Grinder Machine Pin Grinding Crusher

Pin Grinding Crusher Cyclone pulse vacuum crusher

Cyclone pulse vacuum crusher Spice Crusher

Spice Crusher