Minerals Coarse Crusher

It can crush or finely grind medium-hard minerals to reduce their volume and achieve the required particle size. Depending on the Coarse Crusher model, its price ranges from $300 for a small one to $45,000 for a large one.

Crushing capacity: 50-1000 tons/hour

Feed size: 300-1600mm

Output size: 30-350mm

Applications: Suitable for coarse and fine crushing of various minerals, such as iron ore, copper ore, gold ore, granite, limestone, etc.

What is Minerals Coarse Crusher?

Minerals Coarse Crusher is a machine used for pre-crushing mineral raw materials. It can reduce the volume of mined mineral raw materials of different sizes by crushing them, so that they can be processed into sizes that can be processed in subsequent processes. Its feed particle size does not exceed 1600mm, and the output particle size is 25-350mm, which can be adjusted according to needs.

Minerals Coarse Crusher crushing capacities range from 50 to 1000 tons per hour, depending on the model. Common models include jaw crushers for crushing high-hardness minerals, gyratory coarse crushers with large crushing capacity and uniform crushing, and vertical crushers with a large crushing ratio suitable for crushing medium and low hardness minerals.

What types of Minerals Coarse Crusher are there?

There are three types of mineral coarse crushers: jaw, gyratory, and hammer. They can be used to crush minerals of varying hardness to standard particle sizes, but they differ in crushing capacity, output particle size, and operating principle.

Jaw Minerals Coarse Crusher: This type uses a fixed jaw plate and a movable jaw plate to open and close, crushing minerals. It has a simple structure, high wear resistance, and produces uniform particle size. It is suitable for primary crushing of high-hardness minerals such as granite, basalt, and quartzite with a particle size ≤1200mm. Its processing capacity can reach 50-500 tons per hour, with a crushed particle size of 80-350 mm.

Gyratory Minerals Coarse Crusher: This type uses an eccentric shaft to drive a rotating movable cone, which crushes minerals by squeezing them against a fixed cone. It produces finer crushed particles and a higher finished particle size. Its processing capacity is higher than that of a jaw crusher, reaching 100-800 tons per hour, with an output particle size of 50-200 mm. It can process medium-hard to hard minerals such as limestone, iron ore, and copper ore.

Hammer Minerals Coarse Crusher: This type of crusher uses a high-speed rotating hammer to strike minerals, resulting in high crushing efficiency and finer particles. It has a processing capacity of 30-300 tons per hour and a particle size of 30-150 mm. It can be used for coarse crushing of brittle minerals such as coal, gypsum, and shale.

What are the advantages of Minerals Coarse Crusher?

Minerals Coarse Crusher can handle various types and varieties of minerals, from brittle to high-hardness. Depending on the properties of the material being crushed, different models such as jaw crushers, rotary crushers, and hammer crushers can be selected. The crushed material has a particle size of 10-50mm, high uniformity, and a large processing capacity of 50-500 tons per hour. It can be used in small workshops to large mines. Customization is also available based on parameters such as product size, crushing chamber type, material, and power configuration.

Minerals Coarse Crusher parameters

| Model | Applicable hardness (Mohs) | Maximum feed (mm) | Discharge size (mm) | Production capacity (t/h) | Power consumption (kW·h/t) |

| Jaw crusher | 5-9 | 1200 | 100-350 | 60-1160 | 1.2-1.8 |

| Gyratory crusher | 5-8 | 1525 | 150-300 | 2000-10000 | 0.6-1.0 |

| Hammer crusher | 3-6 | 1000 | 30-80 | 60-3000 | 0.8-1.2 |

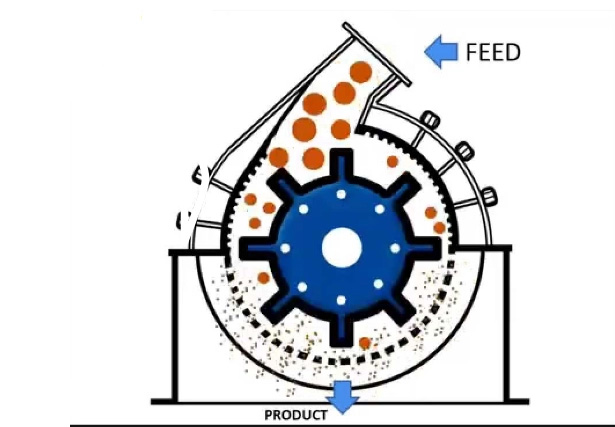

What is the principle of Minerals Coarse Crusher?

When the Minerals Coarse Crusher is in operation, the minerals enter the casing through the feed inlet and fall onto a high-speed rotating rotor equipped with a row of heavy hammers, reaching speeds of several hundred revolutions per minute. As the rotor rotates, the hammers, carrying inertia, forcefully strike the minerals, breaking large, irregular pieces into smaller ones. The crushed material repeatedly collides inside the casing and is further compressed and ground by the gaps between the hammers and the casing wall. Finally, the material that meets the requirements passes through the screen at the bottom and exits from the discharge outlet. Larger pieces that are not properly crushed remain in the crushing chamber and continue to be impacted until they can pass through the screen holes.

What types of ores can be crushed by Minerals Coarse Crusher?

Minerals Coarse Crusher can be used for crushing high-hardness, medium-low-hardness, high-mud content, and brittle minerals with a particle size ≤1600mm. The output particle size after crushing is adjustable from 25-300mm. It can be used for mineral crushing in mining, metallurgy, building materials, chemical and other industries.

For high-hardness ores with a Mohs hardness ≥7, such as granite, basalt, iron ore, and quartzite, a jaw crusher or gyratory crusher is recommended.

For medium-low-hardness minerals with a Mohs hardness of 3-6, such as limestone, gypsum, coal gangue, and phosphate rock, a heavy hammer crusher or impact crusher can be selected.

For ores with high mud content, such as clay minerals, an anti-clogging jaw crusher or a gridless heavy hammer crusher is required.

Minerals Coarse Crusher Customer Cases

In the aggregate production line of a highway construction project in China, the client used a jaw Minerals Coarse Crusher to process granite raw materials with a hardness of up to 320 MPa. The irregular ore particles were ≤450 mm in size. The equipment has a processing capacity of approximately 150 tons per hour and can operate continuously. The output particle size is precisely controlled between 50-80 mm. During the crushing process, a deep V-shaped crushing chamber is used to prevent material blockage. High-manganese steel liners enhance wear resistance. The finished product has a uniform particle size and cubic shape, without over-crushing, effectively reducing the load on subsequent processing. The equipment operates efficiently, consumes little energy, and requires minimal maintenance, helping the client increase raw material utilization to over 90% and successfully complete the project's aggregate supply task.

Minerals Coarse Crusher Manufacturer

MACHRISE Machinery is a strong manufacturer specializing in minerals coarse crushers, possessing mature production technology and a complete production capacity guarantee. Its main products include jaw crushers, hammer crushers, and gyratory crushers, all made of Mn18Cr2 high-manganese steel and high-chromium wear-resistant materials, with a hardness of HRC48-60, ensuring wear resistance and durability. Customization services are also available, optimizing liners and adjusting discharge port precision to suit different production scenarios based on the properties of minerals with varying hardness. Equipment processing capacities range from 50 to 3000 tons per hour, with adjustable crushing sizes from 10 to 350 mm, and prices ranging from $300 to $50,000.

Coarse crusher

Coarse crusher Agricultural Waste Coarse Crusher

Agricultural Waste Coarse Crusher

Ceramics Coarse Crusher

Ceramics Coarse Crusher